Treatment technology for recycling reverse osmosis concentrated water

A reverse osmosis concentrated water and treatment process technology, which is applied in the field of reverse osmosis concentrated water reuse treatment process, can solve the problems of limited reuse water, huge investment, and increased salinity of influent water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

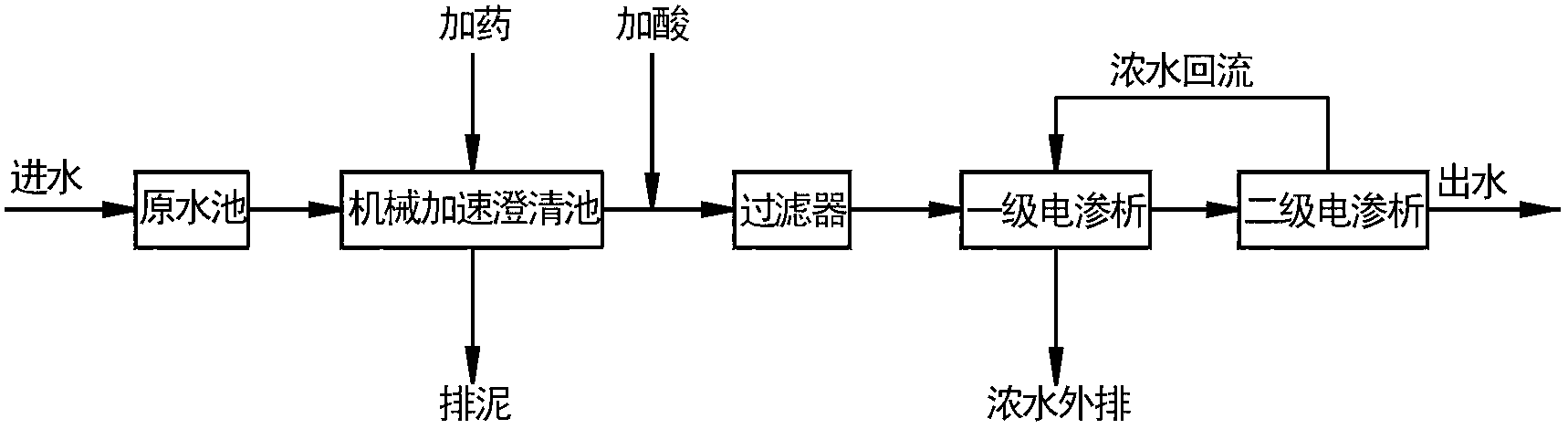

[0021] Such as figure 1 Shown, a kind of reverse osmosis concentrated water reuse treatment process comprises the following steps:

[0022] 1) The reverse osmosis concentrated water with a TDS of about 2000mg / L and a hardness of 12.4mmol / L is added to the raw water tank, and the water quality and water quantity are homogenized by stirring and mixing;

[0023] 2) The effluent from the raw water tank is lifted by the raw water pump and added to the mechanical acceleration clarification tank. The softening reaction and flocculation clarification process are carried out in the mechanical acceleration clarification tank. Calcium hydroxide and calcium carbonate are added to form metal ions to precipitate, so as to remove the temporary hardness and Permanent hardness; adding polymerized ferric sulfate flocculant, under the action of flocculant, the precipitated matter forms a larger alum flower precipitate, the precipitate is collected by pressure filtration, and the supernatant ente...

Embodiment 2

[0029] Such as figure 1 Shown, a kind of reverse osmosis concentrated water reuse treatment process comprises the following steps:

[0030] 1) The reverse osmosis concentrated water with a TDS of about 2500mg / L and a hardness of 15mmol / L is added to the raw water tank, and the water quality and water quantity are homogenized by stirring and mixing;

[0031] 2) The effluent from the raw water tank is lifted by the raw water pump and added to the mechanical acceleration clarification tank. The softening reaction and flocculation clarification process are carried out in the mechanical acceleration clarification tank. Calcium hydroxide and calcium carbonate are added to form metal ions to precipitate, so as to remove the temporary hardness and Permanent hardness; add polyaluminum chloride flocculant, under the action of flocculant, the precipitated matter forms a larger alum flower precipitate, the precipitate is collected by pressure filtration, and the supernatant enters the nex...

Embodiment 3

[0037] Such as figure 1 Shown, a kind of reverse osmosis concentrated water reuse treatment process comprises the following steps:

[0038] 1) The reverse osmosis concentrated water with a TDS of about 3000mg / L and a hardness of 15mmol / L is added to the raw water tank, and the water quality and water quantity are homogenized by stirring and mixing;

[0039] 2) The effluent from the raw water tank is lifted by the raw water pump and added to the mechanical acceleration clarification tank. The softening reaction and flocculation clarification process are carried out in the mechanical acceleration clarification tank. Calcium hydroxide is added to precipitate metal ions to reduce the total hardness in the water. Ferric sulfate and polyacrylamide flocculants, under the action of flocculants, the precipitated matter forms larger alum precipitates, the precipitates are collected by pressure filtration, and the supernatant enters the next treatment process;

[0040] 3) Adjust the PH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com