Method for producing dimethyl ether by carrying out gas-phase dehydration on methanol

A technology of dimethyl ether and dimethyl ether distillation column, which is applied in the field of methanol gas-phase dehydration to produce dimethyl ether, can solve the problems of easy overheating, large volume, increased methanol energy consumption, etc., and achieves easy operation and control, and simple process , The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

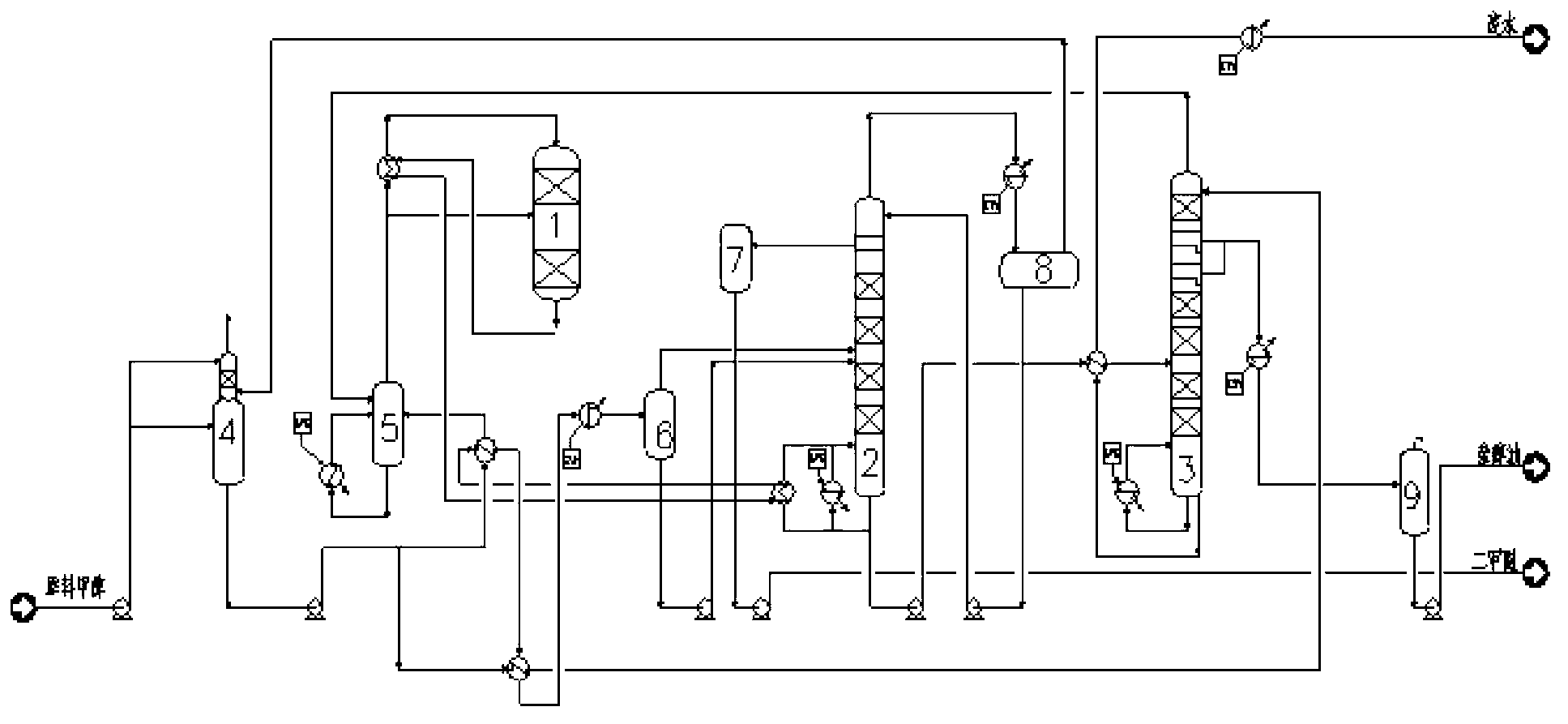

[0037] Such as figure 1 As shown, the raw material methanol flow rate is 206672kg / h, of which the methanol flow rate above the methanol buffer tank is 9613kg / h, the top pressure of the methanol buffer tank is 0.16MPa, and the temperature is 47.1℃; the non-condensable gas flow rate after washing is 3012kg / h, which is directly sent to Torch or fuel gas pipe network. One stream of methanol liquid from the methanol buffer tank is used for the top feed of the methanol rectification tower, and the other stream is sent to the reactor after multi-stage heat exchange and vaporization. It is preheated to about 148°C and enters the methanol gas. The gasification tank uses medium-pressure steam to vaporize the methanol liquid through the methanol vaporizer. The pressure of the methanol vaporization tank is 1.33MPa and the temperature is 148.2℃; the feed flow rate of one section is 153015kg / h, and the heat is exchanged with the outlet gas of the reactor to 260 It enters the reactor with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com