Nanometer composite scaffolds assembled by adopting chitosan scaffold, preparation method and applications thereof

A nano-composite and chitosan technology, applied in the field of nano-materials, can solve the problems of difficult to prepare three-dimensional nano-assembled structures, and achieve the effects of wide applicability, simple operation and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

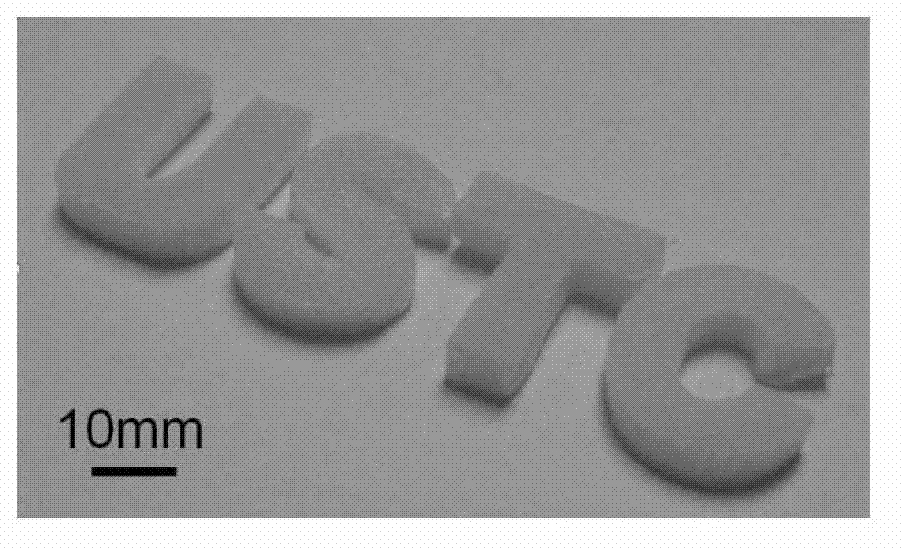

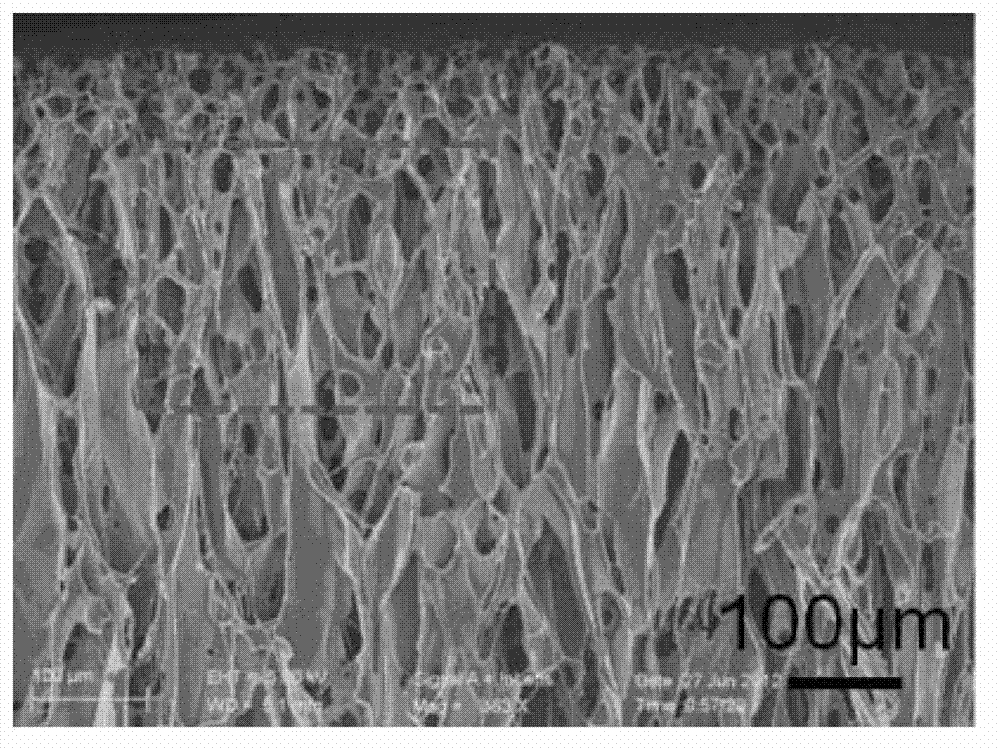

[0059] Dissolve 1.0 g of chitosan powder in 50 mL of 2% aqueous acetic acid to prepare a chitosan solution with a concentration of 20 mg / mL. The frozen metal sheet was pre-frozen to -40°C with liquid nitrogen, and the silicone mold was placed on the stainless steel metal sheet, and then the chitosan solution was poured into the mold, and after freezing and forming, as for the freeze dryer (Labconco-195,-45 ℃) freeze-dried. The lyophilized chitosan scaffold was soaked in NaOH solution with a concentration of 1.0mol / L to neutralize excess acetic acid, and the excess NaOH solution was washed away with distilled water.

[0060] Fe 3 o 4 Preparation of nanoparticles: first prepare solution 1: weigh 2 grams of sodium hydroxide and add it to 20 milliliters of diethylene glycol, vacuumize, vent nitrogen, add a reflux tube, heat to 120 ° C for one hour, and then keep the temperature at 70 ° C. Prepare solution 2: Weigh 0.064 g of anhydrous ferric chloride, 0.288 g of PAA (Mw: 1800),...

Embodiment 2

[0064] The chitosan scaffold was prepared as in Example 1.

[0065] Preparation of Au nanoparticles: Measure 96mL of deionized water into a round bottom flask, add 2mL of 50mM chloroauric acid solution, transfer to 120°C oil bath and boil for half an hour, weigh 0.1144g of trisodium citrate and dissolve in 2.5ml of water , and added to the above reaction system, continued to boil for 10 minutes, took out the flask to stop the reaction. The whole process adds the reflux of the condenser tube. (G. Frens, Controlled Nucleation for Regulation of Particle-Size in Monodisperse Gold Suspensions. Nature-Physical Science 241, 20 (1973).)

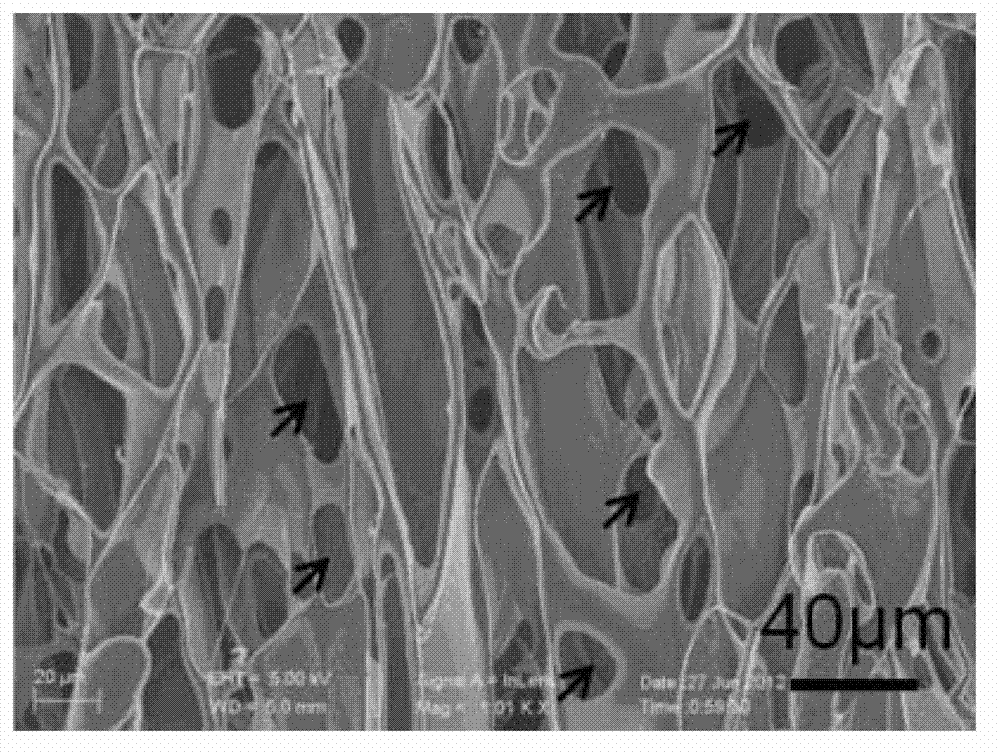

[0066] Immerse the chitosan foam with acetic acid removed into the 5ml aqueous solution of Au nanoparticles prepared above at a concentration of 1mg / mL, repeatedly squeeze and release the foam until the solution is almost clear, so that the Au nanoparticles are adsorbed to the inner wall of the foam channel, and the assembled The composite scaffold...

Embodiment 3

[0069] The chitosan scaffold was prepared as in Example 1.

[0070] Preparation of Ag nanoparticles: measure 96mL of deionized water to a round bottom flask, add 1mL of 50mM silver nitrate solution, transfer to 120°C oil bath and boil for half an hour, weigh 0.1144 grams of trisodium citrate and dissolve in 2.5 milliliters of water, And add in the above reaction system, continue to boil for 5 minutes, take out the flask to stop the reaction. The whole process adds the reflux of the condenser tube. (G. Frens, Controlled Nucleation for Regulation of Particle-Size in Monodisperse Gold Suspensions. Nature-Physical Science 241, 20 (1973).)

[0071] Immerse the chitosan foam with acetic acid removed into the 5ml Ag nanoparticle aqueous solution prepared above at a concentration of 1mg / mL, repeatedly squeeze and release the foam until the solution is almost clear, so that the nanoparticles are adsorbed to the inner wall of the foam channel to obtain an assembly Composite support ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com