Heat tranferring circular reactor with external heat exchanging center and application

A reactor and heat removal technology, applied in ion exchange, other chemical processes, ion exchange regeneration, etc., can solve the problems of large-volume monolithic materials that have not been successfully industrialized, difficulties in scaling up technology, and reduction of reaction heat, etc., to achieve good product quality , good application effect and high mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

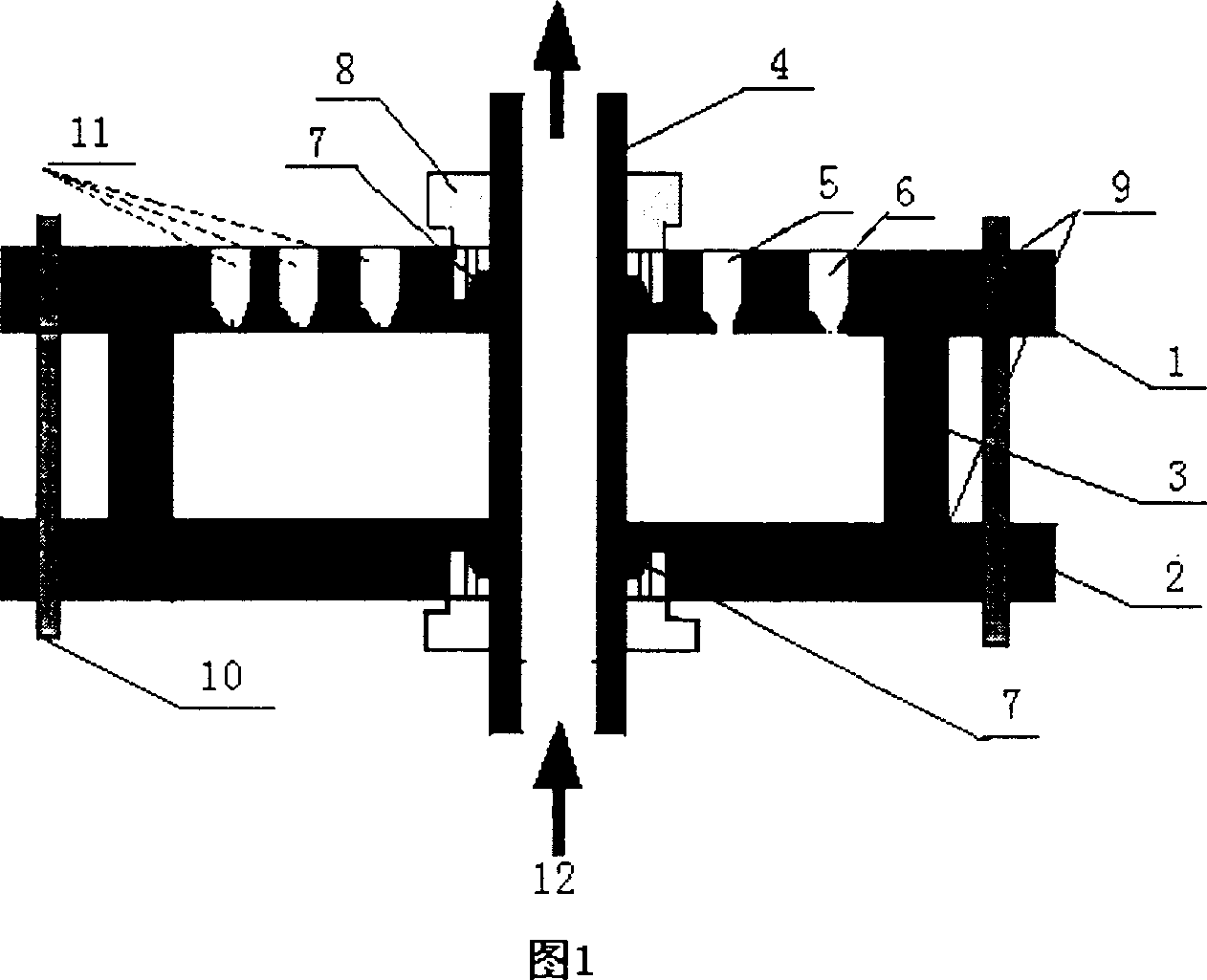

[0029] A heat-removing annular reactor with an external heat exchange center, comprising an upper gland 1, a lower gland 2, and an annular cylinder 3 placed therebetween, a circulating water pipe 4 placed in the middle of the annular cylinder 3, and Through the upper gland 1 and the lower gland 2, the upper gland 1 is provided with a feed port 5, an exhaust port 6 and a thermocouple insertion port 11; the circulating water pipe 4 is connected to the upper gland 1 and the lower gland 2 There is a T-shaped sealing ring A7 on the outside of the T-shaped sealing ring A7, and an external pressure cap 8 is arranged on the outer side of the T-shaped sealing ring A7; a T-shaped sealing ring B9 is also provided at the connection between the upper gland 1 and the lower gland 2 and the annular cylinder 3 ; A locking bolt 10 is provided between the upper gland 1 and the lower gland 2 .

[0030] The preparation process of large-volume annular monolithic porous materials:

[0031] (1) Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com