Method for removing sulfur dioxide from fruit distilled wine

A technology for sulfur dioxide and distilled wine, which is applied in the field of food processing, can solve problems such as waste, and achieve the effects of improving the removal rate, avoiding influence and preventing corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A certain dry white wine, its basic index:

[0029] Alcohol: 11.5%Vol

[0030] Total acid: 6.0g / L (calculated as tartaric acid)

[0031] pH: 3.38

[0032] Total sulfur dioxide: 125.4mg / L.

[0033] 1) First distillation

[0034] Take 1L of distilled base wine, distill and collect 400ml of distilled liquid to obtain a distilled wine, and measure its basic indicators:

[0035] Alcohol: 27.5% Vol

[0036] Total acid: 0.49g / L (calculated as acetic acid)

[0037] pH: 2.80

[0038] Total sulfur dioxide: 214.2mg / L.

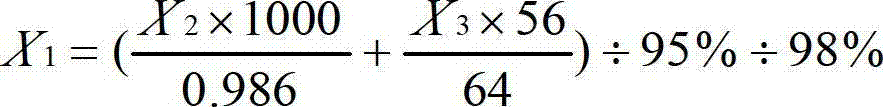

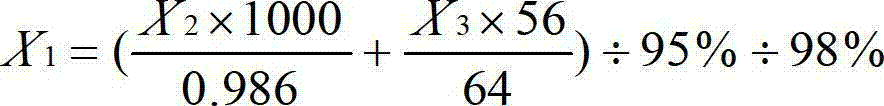

[0040] According to the formula X 1 = ( X 2 × 1000 0.986 + X 3 × 56 64 ) ...

Embodiment 2

[0050] A certain sweet red wine, its basic index:

[0051] Alcohol: 11.0%Vol

[0052] Total acid: 7.2g / L (calculated as tartaric acid)

[0053] pH: 3.24

[0054] Total sulfur dioxide: 49.7mg / L.

[0055] 1) First distillation

[0056] Take 1L of distilled base wine, distill and collect 400ml of distilled liquid to obtain a distilled wine, and measure its basic indicators:

[0057] Alcohol: 28%Vol

[0058] Total acid: 0.45g / L (calculated as acetic acid)

[0059] pH: 2.67

[0060] Total sulfur dioxide: 63.6mg / L.

[0062] According to the formula X 1 = ( X 2 × 1000 0.986 + X 3 × 56 64 ) ...

Embodiment 3

[0072] A dry red wine, its basic indicators:

[0073] Alcohol: 12%Vol

[0074] Total acid: 7.0g / L (calculated as tartaric acid)

[0075] pH: 3.32

[0076] Total sulfur dioxide: 110.5mg / L.

[0077] 1) First distillation

[0078] Take 1L of distilled base wine, distill and collect 400ml of distilled liquid to obtain a distilled wine, and measure its basic indicators:

[0079] Alcohol: 28%Vol

[0080] Total acid: 0.7g / L (calculated as acetic acid)

[0081] pH: 2.74

[0082] Total sulfur dioxide: 198.2mg / L.

[0083] 2) Add calcium oxide

[0084] According to the formula X 1 = ( X 2 × 1000 0.986 + X 3 × 56 64 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com