Method for processing surfaces of composite antimicrobial coatings coated with copper layer substrates

A composite antibacterial and surface treatment technology, applied in the field of surface treatment of composite antibacterial coatings on copper-coated substrates, can solve the problems of poor sustained antibacterial effect, poor wear resistance of the coating, easy oxidation, etc. High bacterial efficiency and long-term effective antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

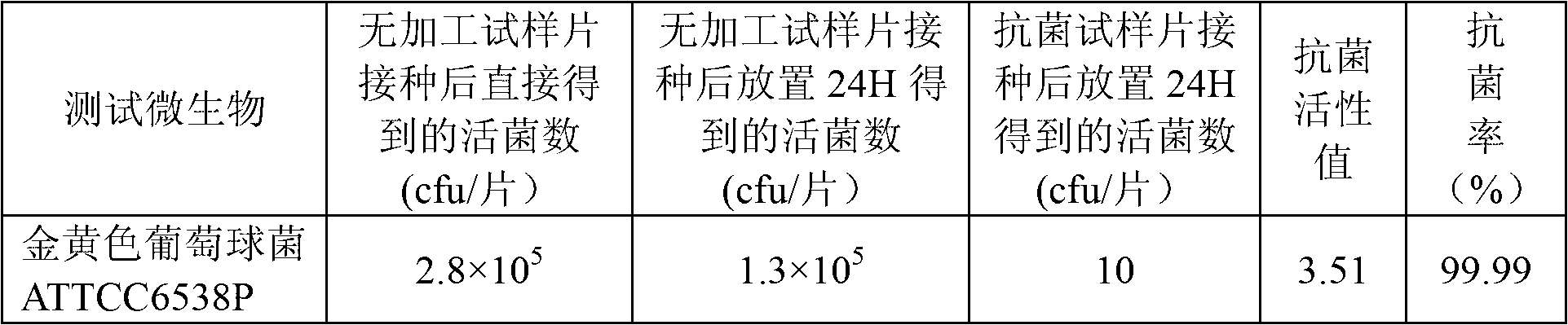

Embodiment 1

[0025] An example of PC / ABS mirror case coated with antibacterial coating, its technological process is as follows:

[0026] (1) Clean and activate the surface of the PC / ABS mirror case after acid copper plating

[0027] The cleaning process can be: rinse with pure water for 1min. The activation treatment method can adopt the formulation of the activation plating solution provided by Renyuan Company in Japan as follows: activator V-3745g / L, activation time is 1min, and the temperature is room temperature.

[0028] (2) Plating semi-gloss nickel

[0029] The semi-bright nickel plating solution can adopt the formula of electroplating semi-bright nickel provided by Renyuan Company in Japan as follows: nickel sulfate NiSO 4 280~300g / L, nickel chloride NiCl 2 30~40g / L, boric acid H 3 BO 3 35~45g / L, pH 4.2~4.3, brightener CF-24T 1~3ml / L, brightener 82-K 1~3ml / L, bath temperature 50℃, DC current density 2A / dm 2 , Plating time is 30min.

[0030] (3) Plating antibacterial nickel ...

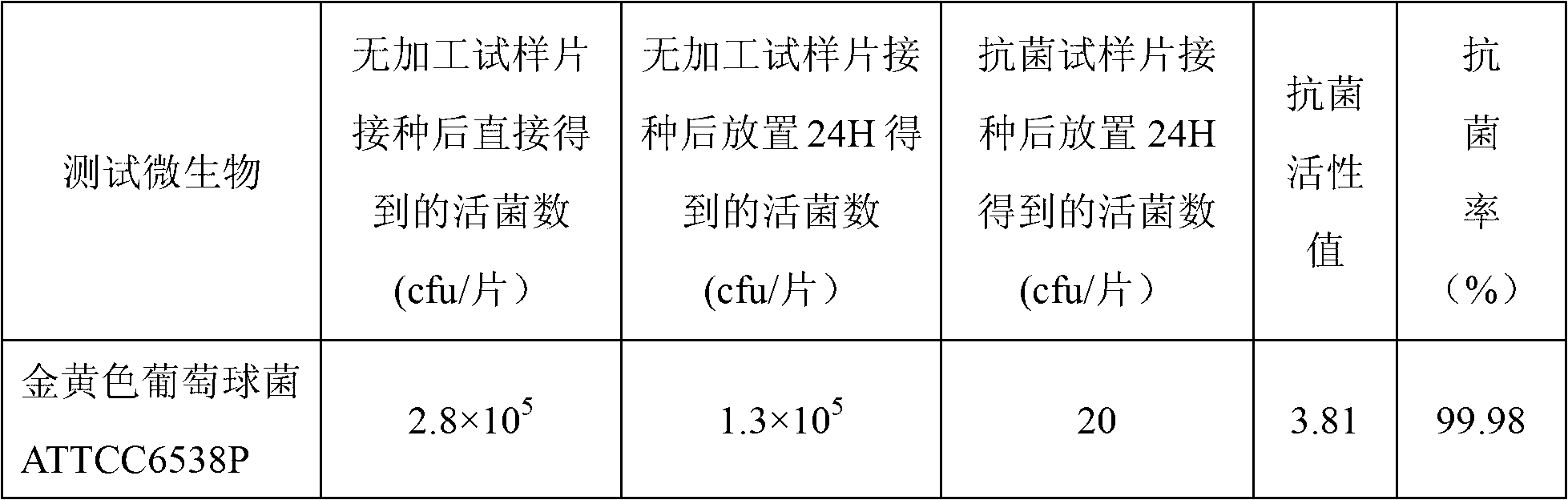

Embodiment 2

[0042] Application example of antibacterial coating on metal copper faucet base material, the process flow is as follows:

[0043] (1) Cleaning and surface activation of the copper faucet surface after acid copper plating

[0044] The cleaning process can be: rinse with pure water for 2 minutes. The activation treatment method can adopt the formulation of the activation plating solution provided by Renyuan Company in Japan as follows: activator V-3745g / L, activation time is 2min, and the temperature is room temperature.

[0045] (2) Plating semi-gloss nickel

[0046] The semi-bright nickel plating solution can adopt the formula of electroplating semi-bright nickel provided by Renyuan Company in Japan as follows: nickel sulfate NiSO 4 280~300g / L, nickel chloride NiCl 2 30~40g / L, boric acid H 3 BO 3 35~45g / L, pH 4.2~4.3, brightener CF-24T 1~3ml / L, brightener 82-K 1~3ml / L, bath temperature 60℃, DC current density 5A / dm 2 , plating time is 5min.

[0047] (3) Plating antibac...

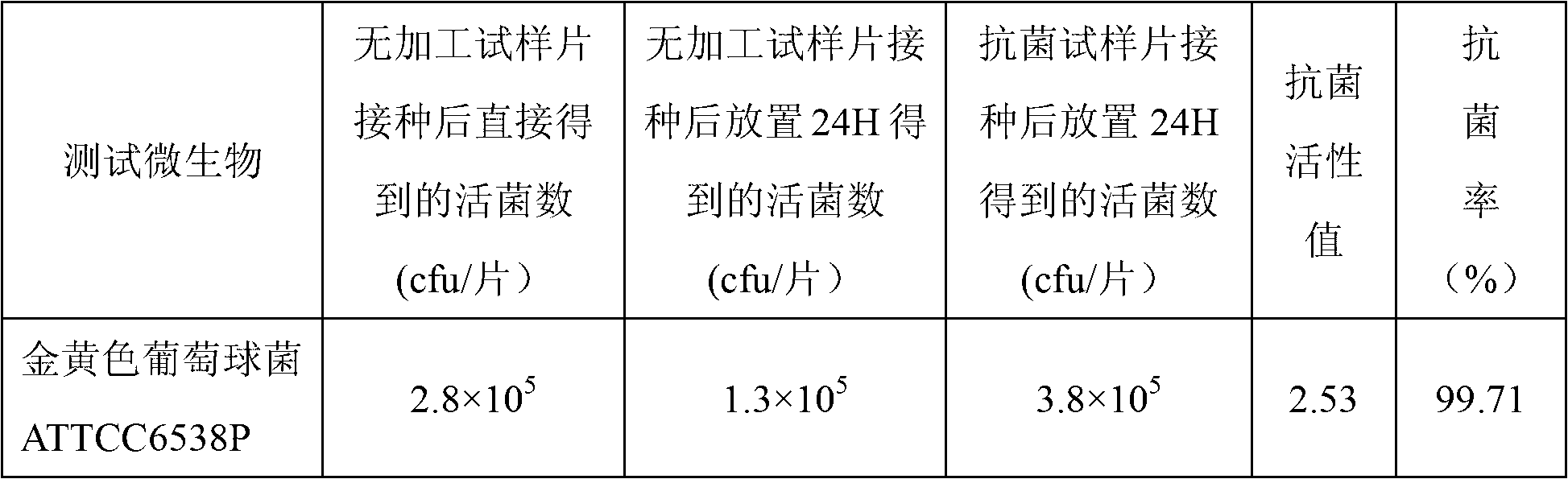

Embodiment 3

[0059] An example of an ABS substrate antibacterial coating shower body, the process flow is as follows:

[0060] (1) Clean and activate the surface of the ABS substrate shower body after acid copper plating

[0061] The cleaning process can be: rinse with pure water for 1min. The activation treatment method can adopt the formulation of the activation plating solution provided by Renyuan Company in Japan as follows: activator V-3745g / L, activation time is 1min, and the temperature is room temperature.

[0062] (2) Plating semi-gloss nickel

[0063] The semi-bright nickel plating solution can adopt the formula of electroplating semi-bright nickel provided by Renyuan Company in Japan as follows: nickel sulfate NiSO 4 280~300g / L, nickel chloride NiCl 2 30~40g / L, boric acid H 3 BO 3 35~45g / L, pH 4.2~4.3 brightener CF-24T 1~3ml / L, brightener 82-K 1~3ml / L, bath temperature 55℃, DC current density 3A / dm 2 , Plating time is 30min.

[0064] (3) Plating antibacterial nickel

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com