Preparation method and application of novel adhesive antibacterial temperature-tolerant functional hydrogel

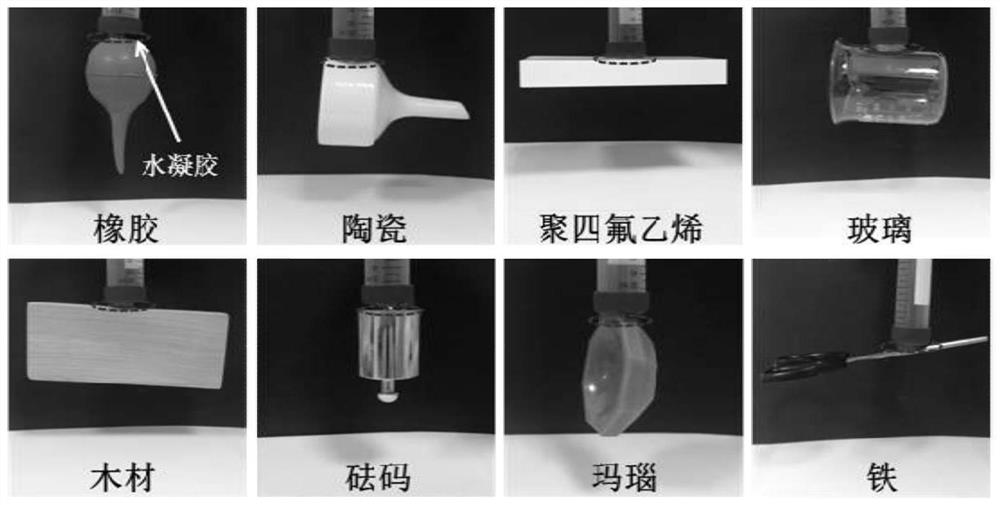

A functional water and hydrogel technology, applied in bandages, medical science and other directions, can solve the problems of sticking wounds, easy infection, easy scabs, etc., and achieve the effects of lasting antibacterial properties, avoiding secondary damage and easy preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

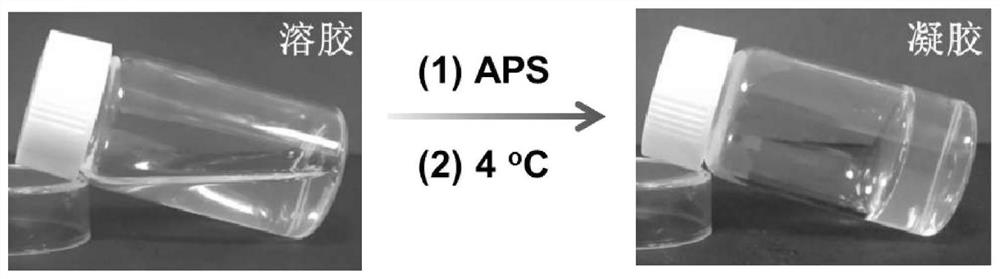

[0019] (1) Add 1.0 g of gelatin to a round bottom flask containing 20 mL of deionized water / glycerol (volume ratio 7:3) mixed solution, stir continuously at 60°C for half an hour, after the gelatin is completely dissolved, slowly add 2.0 g of polylysine (ε-PL, molecular weight 4000–4300 kDa), stirring was continued for 20 minutes. After cooling to room temperature, 6.0 g of acrylamide (AM) monomer, 6.0 mg of N,N'-methylenebisacrylamide (MBA) and 120.0 mg of ammonium persulfate (APS) were added in sequence, and stirred evenly. Then the obtained mixed solution was poured into a mold and reacted at 60°C for 5 h to form a semi-penetrating network hydrogel.

[0020] (2) Put the above hydrogel in a refrigerator at 4° C. for 60 minutes to react to form the final multifunctional double network hydrogel.

Embodiment 2

[0022] (1) Add 1.0 mL of gelatin to a round bottom flask containing 20 mL of deionized water / glycerin (volume ratio 4:1) mixed solution, and stir continuously at 60°C for half an hour. After the gelatin is completely dissolved, slowly add 2.0g quaternary ammonium chitosan, continue to stir for 20 minutes. After cooling to room temperature, 6.0 g of acrylamide (AM) monomer, 6.0 mg of N,N'-methylenebisacrylamide (MBA) and 120.0 mg of ammonium persulfate (APS) were added in sequence, and stirred evenly. Then the obtained mixed solution was poured into a mold and reacted at 60°C for 5 h to form a semi-penetrating network hydrogel.

[0023] (2) Put the above hydrogel in a refrigerator at 4° C. for 60 minutes to react to form the final multifunctional double network hydrogel.

Embodiment 3

[0025] (1) Add 1.0 mL of gelatin to a round bottom flask containing 20 mL of deionized water / glycerin (volume ratio 4:1) mixed solution, and stir continuously at 60°C for half an hour. After the gelatin is completely dissolved, slowly add 2.0 g of polyhexamethyleneguanidine hydrochloride, and continue stirring for 20 minutes. After cooling to room temperature, 6.0 g of acrylamide (AM) monomer, 6.0 mg of N,N'-methylenebisacrylamide (MBA) and 120.0 mg of ammonium persulfate (APS) were added in sequence, and stirred evenly. Then the obtained mixed solution was poured into a mold and reacted at 60°C for 5 h to form a semi-penetrating network hydrogel.

[0026] (2) Put the above hydrogel in a refrigerator at 4° C. for 60 minutes to react to form the final multifunctional double network hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com