Antibacterial rubber-plastic product and preparation method thereof

A product, rubber and plastic technology, applied in the field of antibacterial rubber and plastic products and their preparation, can solve the problems of great harm to human body, high cost of use, heavy metal pollution, etc., and achieve the effect of long-term effective antibacterial effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

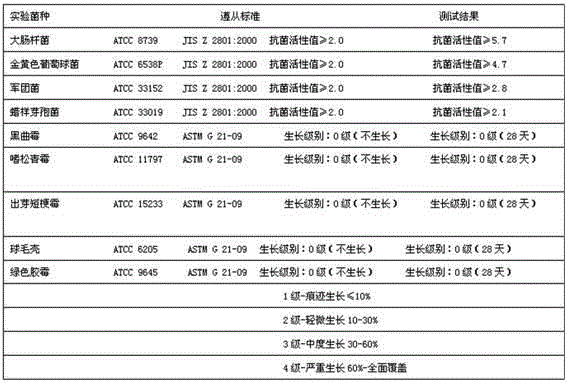

Image

Examples

Embodiment 1

[0022] An antibacterial rubber and plastic product, comprising the following components in parts by weight: dispersant HT-5168 0.5, calcium stearate 0.1, stearic acid 0.2, polyethylene glycol 0.9, antioxidant 4020 0.1, active zinc oxide 0.5, Sulfur powder 0.5, solid paraffin 2, antimony trioxide 2, zinc borate 1, carbendazim 0.2, N-octylisothiazolinone 0.2, nitrile rubber 10, aluminum hydroxide 20, polyvinyl chloride resin 12, chlorine Paraffin wax 20, epoxy soybean oil 2, carbon black N550 1.5, azodicarbonamide 10, rubber accelerator 1. Among them, the rubber accelerator is proportioned in parts by weight: 40 zinc dibutyl dithiocarbamate, 10 diphenylguanidine, 5 bispentamethylenethiuram tetrasulfide, 10 nitrile rubber, 8 chlorinated paraffin, anti-scorch Agent CTP 2.

[0023] A preparation method for an antibacterial rubber and plastic product, comprising the following steps:

[0024] (1) take raw materials by each component weight described in claim 1:

[0025] (2) An...

Embodiment 2

[0037]An antibacterial rubber and plastic product, comprising the following components in parts by weight: dispersant HT-5168 1, calcium stearate 0.3, stearic acid 0.25, polyethylene glycol 1.5, antioxidant 4020 0.4, active zinc oxide 0.65, Sulfur powder 0.8, solid paraffin 2.6, antimony trioxide 4, zinc borate 1.3, carbendazim 0.4, N-octylisothiazolinone 0.6, nitrile rubber 12, aluminum hydroxide 22, polyvinyl chloride resin 16, chlorine Chemical paraffin 25, epoxy soybean oil 3, carbon black N550 2, azodicarbonamide 12, rubber accelerator 2. Wherein the rubber accelerator is proportioned by weight: 50 zinc dibutyl dithiocarbamate, 15 diphenylguanidine, 8 bispentamethylenethiuram tetrasulfide, 15 nitrile rubber, 12 chlorinated paraffin, anti-scorch Agent CTP 3.

[0038] A preparation method for an antibacterial rubber and plastic product, comprising the following steps:

[0039] (1) take raw materials by each component weight described in claim 1:

[0040] (2) Aniseed banb...

Embodiment 3

[0052] An antibacterial rubber and plastic product, comprising the following components in parts by weight: dispersant HT-5168 1.5, calcium stearate 0.5, stearic acid 0.3, polyethylene glycol 1.8, antioxidant 4020 0.5, active zinc oxide 0.8, Sulfur powder 1, solid paraffin wax 3, antimony trioxide 2, zinc borate 2, carbendazim 0.5, N-octylisothiazolinone 0.8, nitrile rubber 13, aluminum hydroxide 30, polyvinyl chloride resin 18, chlorine Paraffin wax 30, epoxy soybean oil 5, carbon black N550 3, azodicarbonamide 15, rubber accelerator 3. Among them, the rubber accelerator is proportioned in parts by weight: zinc dibutyldithiocarbamate 60, diphenylguanidine 20, bispentamethylenethiuram tetrasulfide 10, nitrile rubber 20, chlorinated paraffin 15, anti-scorch Agent CTP 5.

[0053] A preparation method for an antibacterial rubber and plastic product, comprising the following steps:

[0054] (1) take raw materials by each component weight described in claim 1:

[0055] (2) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com