Weaving method of fireproof and mildewproof fabric

A mildew-proof and fabric technology, which is applied in the manufacture of fire-resistant and flame-retardant filaments, textiles and paper, conjugated artificial filaments, etc., can solve the problems of losing the anti-mildew effect and poor durability, and achieve strong durability and good durability , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

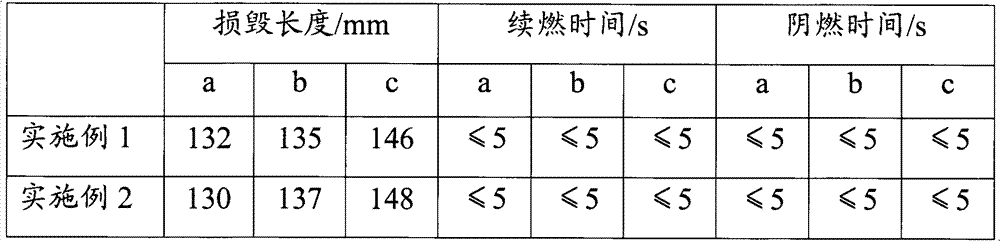

Embodiment 1

[0019] Preparation of fireproof and antifungal agent:

[0020] Raw material preparation:

[0021] 50 parts of triphenylphosphine oxide,

[0022] Hexamethylolmelamine 30 parts,

[0023] Penetrant JFC 2 parts,

[0024] 5 parts of silane coupling agent.

[0025] Preparation of fireproof and mildew proof masterbatch:

[0026] Blend and dry the fire-proof and anti-mold agent with the fiber base material, enter the screw extruder to melt, blend and extrude, and granulate to obtain the fire-proof and anti-mold masterbatch. The weight ratio of the fiber base material to the fire-proof and anti-mold agent is 100:5 ;

[0027] Production of fire and mildew resistant fabrics:

[0028] After blending the fire-proof and anti-mildew masterbatch and fiber slices at a mass ratio of 1:20, the fire-proof and anti-mold fibers are formed after spinning, winding and stretching, and then blended with wool at a ratio of 2:1 to obtain a fire-proof and anti-mold fabric.

Embodiment 2

[0030] Preparation of fireproof and antifungal agent:

[0031] Raw material preparation:

[0032] 65 parts of triphenylphosphine oxide,

[0033] Hexamethylolmelamine 20 parts,

[0034] Penetrant JFC 8 parts,

[0035] 2 parts of silane coupling agent.

[0036] Preparation of fireproof and mildew proof masterbatch:

[0037] Blend and dry the fire-proof and anti-mold agent with the fiber base material, enter the screw extruder to melt, blend and extrude, and granulate to obtain the fire-proof and anti-mold masterbatch. The weight ratio of the fiber base material to the fire-proof and anti-mold agent is 100:10 ;

[0038] Production of fire and mildew resistant fabrics:

[0039] After blending the fire-proof and mildew-proof masterbatch and fiber chips at a mass ratio of 1:10, the fire-proof and mildew-proof fibers are formed after spinning, winding and stretching, and then blended with kapok fibers at a ratio of 1:1 to obtain fire-proof and mildew-proof fabrics .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com