Method and system for internal compression process space division reducing high-pressure plate type heat exchanger temperature differences

A high-pressure plate and heat exchanger technology, used in heat exchange equipment, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of foreign matter removal, no purging port, etc., to prevent breakdowns and stop and ensure a long cycle. Stable operation and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

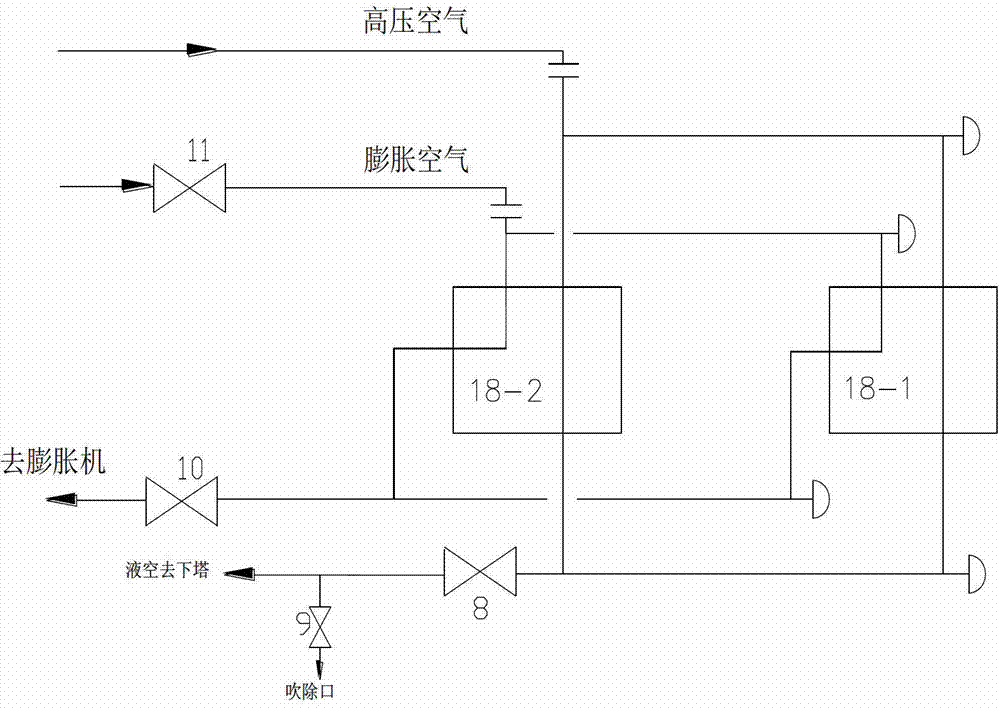

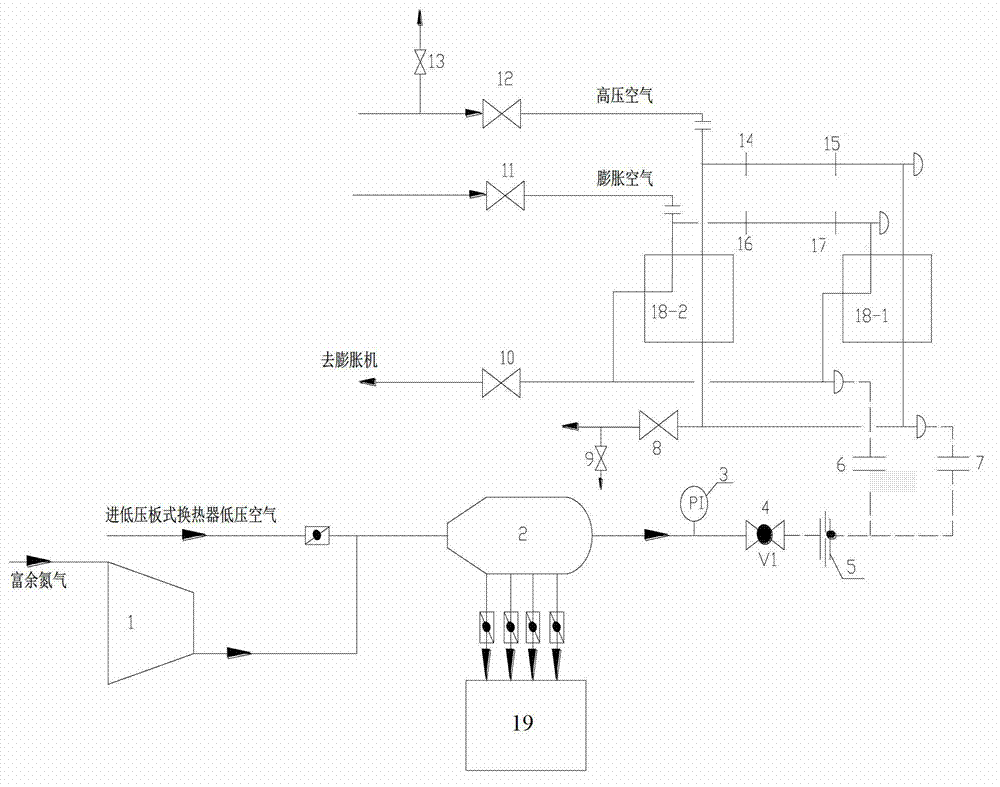

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0041] In the description of this patent, "high plate" refers to a high pressure plate heat exchanger.

[0042] Yankuang Lunan Fertilizer Plant 28000m 3 / h air separation is the (leading) supporting device of our factory's dual-structure adjustment project. The operation quality of this device directly affects the stable operation of the entire dual-structure production system. 28000m 3 / h air separation adopts the internal compression process, liquid oxygen and liquid nitrogen are compressed by the liquid pump, exchange heat with high-pressure air in the high-pressure plate heat exchanger, and then send them to the rear system, so the effect of high-pressure plate heat exchange directly affects the entire system Production load and energy consumption.

[0043] 28000m 3 / h The temperature difference of the air separation high-pressure plate heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com