Method and device for detecting mass flow rate of pulverized coals in process of conveying pulverized coals

A technology for pulverized coal quality and pulverized coal transportation, which is applied in mass flow measurement devices, indirect mass flow meters, etc., can solve problems such as large errors in pulverized coal measurement methods, and achieve the goals of improving measurement accuracy, performance, and spatial resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

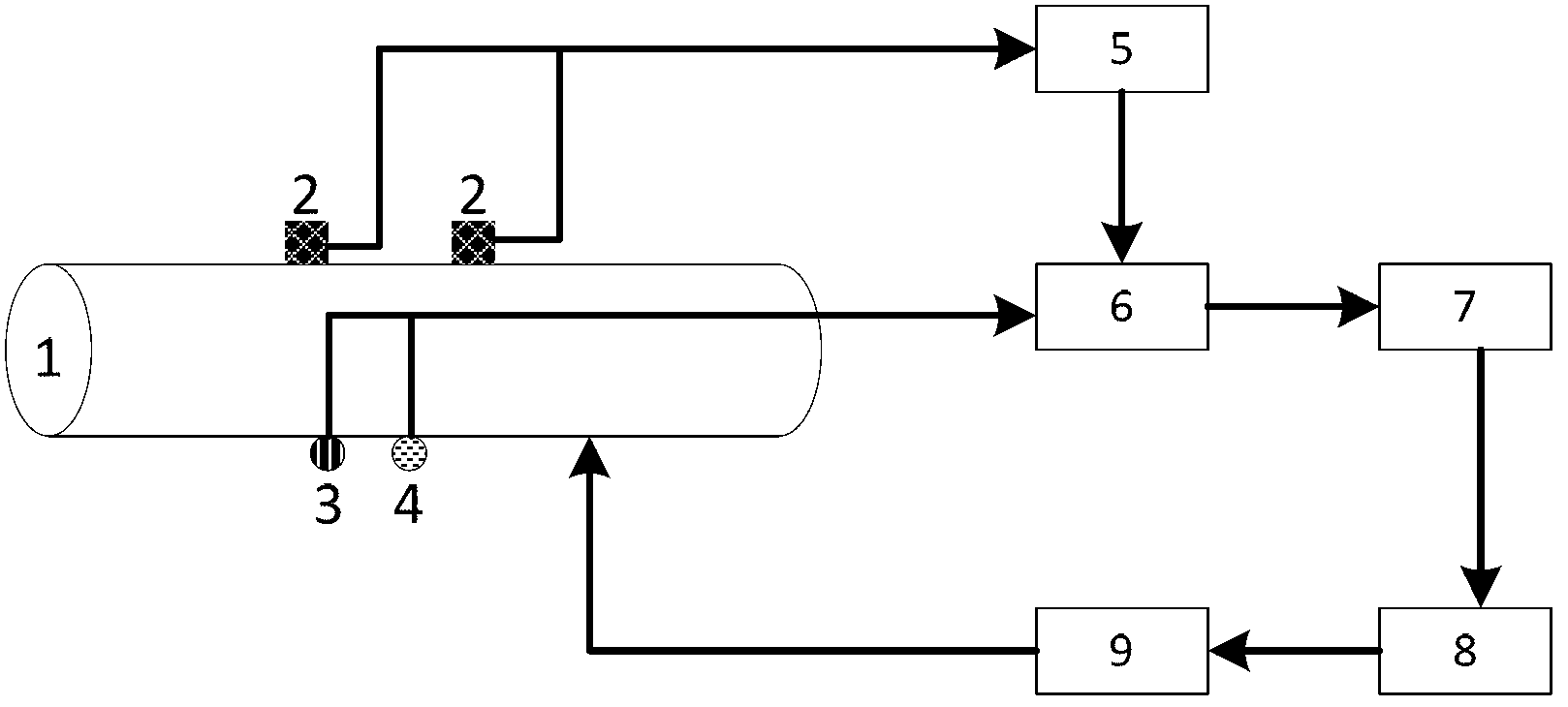

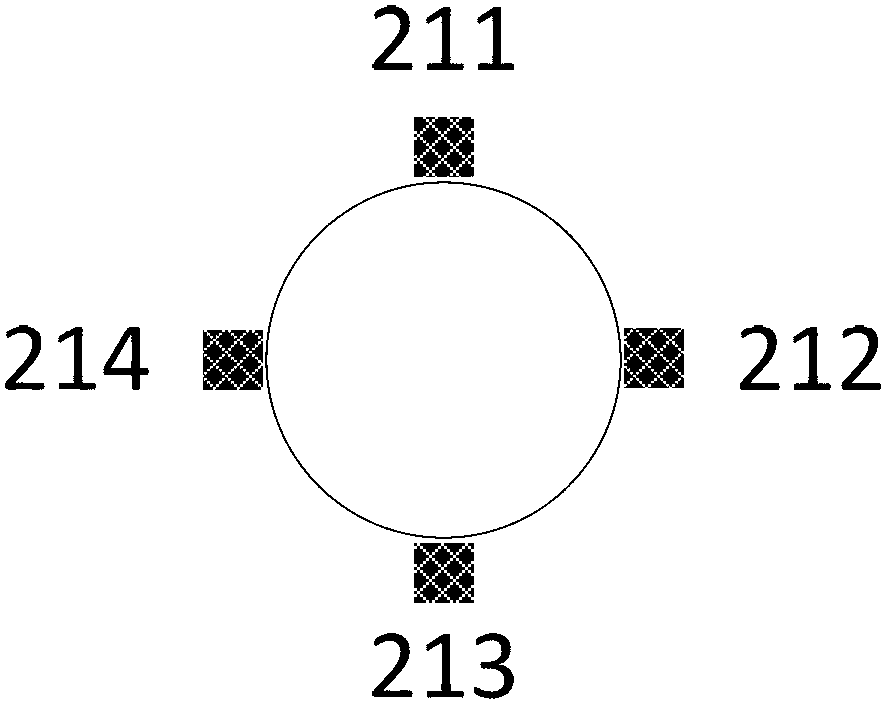

[0040] Such as figure 1 As shown, the detection device of this embodiment includes a pulverized coal conveying pipeline 1, two sets of acoustic wave sensor groups 2, a temperature sensor 3, a pressure sensor 4, a signal amplification device 5, a signal acquisition device 6, a signal processing device 7, an output display The device 8 and the control device 9; the acoustic wave sensor group 2 is respectively arranged on the outer wall of the pipeline 1, the temperature sensor 3 and the pressure sensor 4 are respectively inserted into the pipeline 1, and the acoustic wave sensor group 2 is connected with the signal amplification device 5 to convert the acoustic wave signal into an electrical signal for transmission To the signal amplifying device 5, the signal amplifying device 5 is connected to the signal collecting device 6, and the amplified signal is transmitted to the signal collecting device 6, and the pressure sensor 4 is connected to the signal collecting device 6, and th...

Embodiment 2

[0069] Present embodiment is as follows to the detection process of pulverized coal moisture content:

[0070] The present invention is used to measure the moisture content of pulverized coal in the pipeline 1 . The acoustic wave sensor selected in this embodiment is an acceleration sensor. The moisture content of pulverized coal was measured off-line on a hygrometer after sampling. The moisture content of pulverized coal varies from 0.5wt% to 2.5wt%. The frequency response range of the acceleration sensor is 1 ~ 30kHz, the system sampling frequency is 100KHz, and the sampling time is 10s. Other experimental devices are the same as in Example 1.

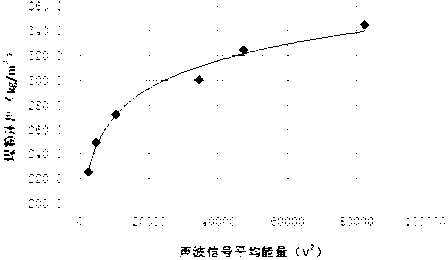

[0071] The sound wave signal is preprocessed by smoothing and orthogonal signal correction, and the preprocessed sound wave signal is analyzed by Fourier transform. The main frequency of the sound wave signal when the moisture content is 0 is used as the reference value, and the first group of sound waves is taken. The average fr...

Embodiment 3

[0074] Present embodiment is as follows to the detection process of pulverized coal particle size:

[0075] The invention is used to measure the coal powder particle size in the pipeline 1 . The particle size of pulverized coal is obtained by sampling and analyzing offline on a laser particle size analyzer. The particle size of pulverized coal varies from 20 microns to 50 microns. The frequency response range of the acoustic emission sensor is 20-300KHz, the system sampling frequency is 700KHz, and the sampling time is 20s. Other experimental equipment is identical with embodiment 1,

[0076] The acoustic signal was preprocessed with multivariate scatter correction. Using wavelet analysis to analyze the preprocessed acoustic signal, the steps include:

[0077] 1) Use the orthogonal wavelet as the wavelet mother function to decompose the signal by wavelet;

[0078] 2) Use the wavelet decomposition coefficient to represent the signal energy, calculate the total energy of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com