Intelligent controller for steamed bun cutter

A technology of an intelligent controller and a steamed bread machine, which is applied in the sequence/logic controller of program control, electrical program control, dough forming and cutting equipment, etc. The problem of low level is easy to query records, reduce equipment failure points, and increase the effect of management system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

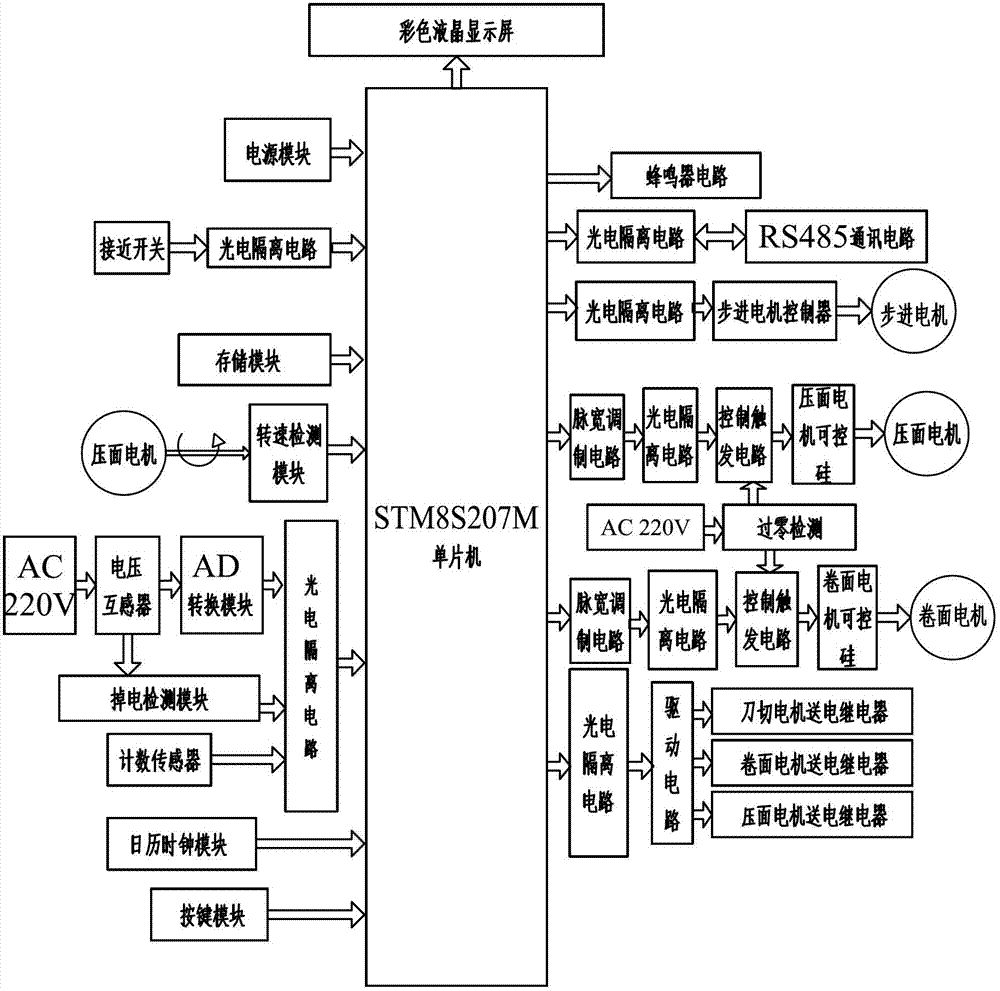

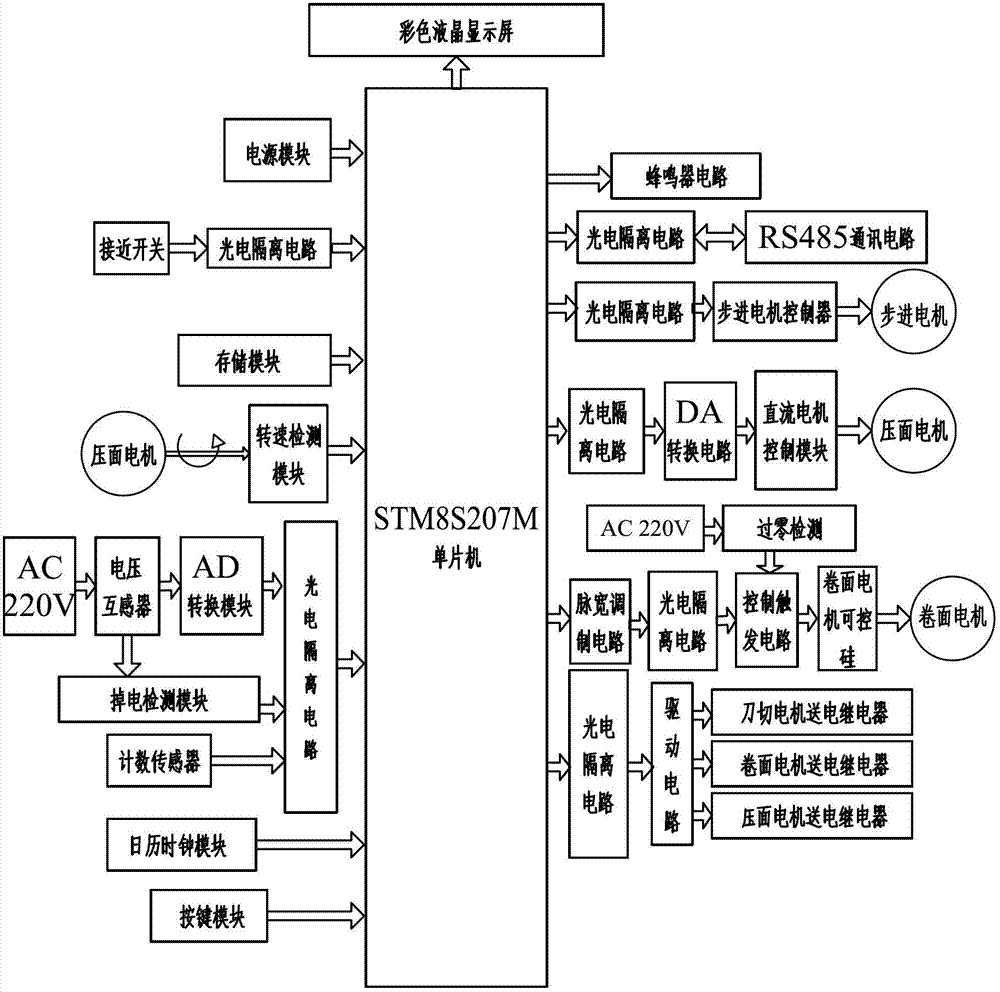

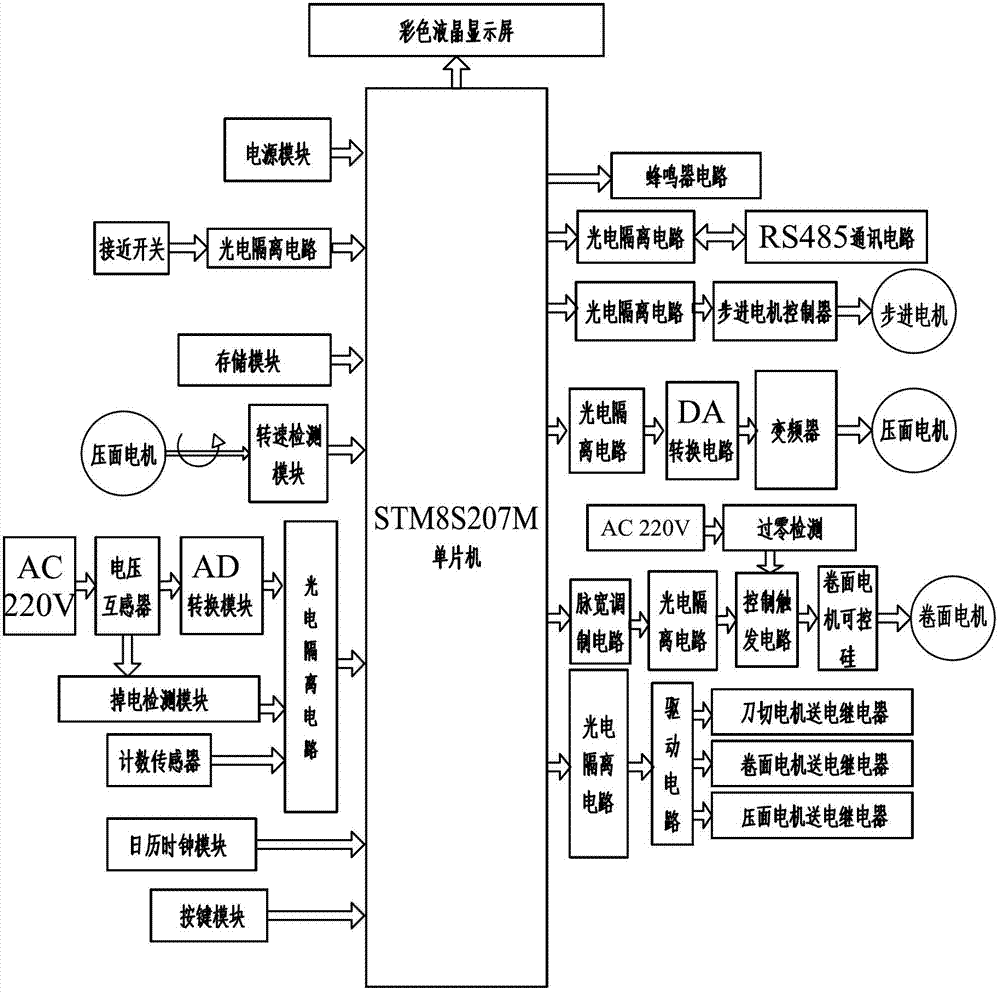

[0038] figure 1 It is a functional block diagram of Embodiment 1 of the present invention. Such as figure 1 As shown, an intelligent controller of a knife-cut steamed bun machine of the present invention includes a shell made of aluminum alloy, and also includes:

[0039] The ST series industrial-grade STM8S207MB single-chip microcomputer installed in the housing and the power supply module, storage module, pressure surface motor speed detection module, analog-to-digital conversion module, power-down detection module, calendar clock module, and motor power transmission control module respectively connected to the single-chip microcomputer , a zero-crossing detection module, a pressing motor control module, a rolling motor control module, a knife-cutting motor control module, a display signal output circuit, a buzzer circuit and a communication interface circuit, the pressing motor speed detection module and the pressing motor connected, the motor power transmission control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com