Chymotrypsin composition freeze-dried powder and preparation method thereof

A technology for chymotrypsin and composition, which is applied in the field of chymotrypsin composition freeze-dried powder and its preparation, can solve the problems of chymotrypsin susceptible bacteria, unstable aqueous solution, poor thermal stability of chymotrypsin, etc. Stable, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A chymotrypsin composition freeze-dried powder, the formula is: chymotrypsin 40 million units; dextran 20:40g; sorbitol 2g.

[0063] The average porosity of the freeze-dried powder of the chymotrypsin composition is 85%.

[0064] The preparation method of described chymotrypsin composition freeze-dried powder comprises the steps:

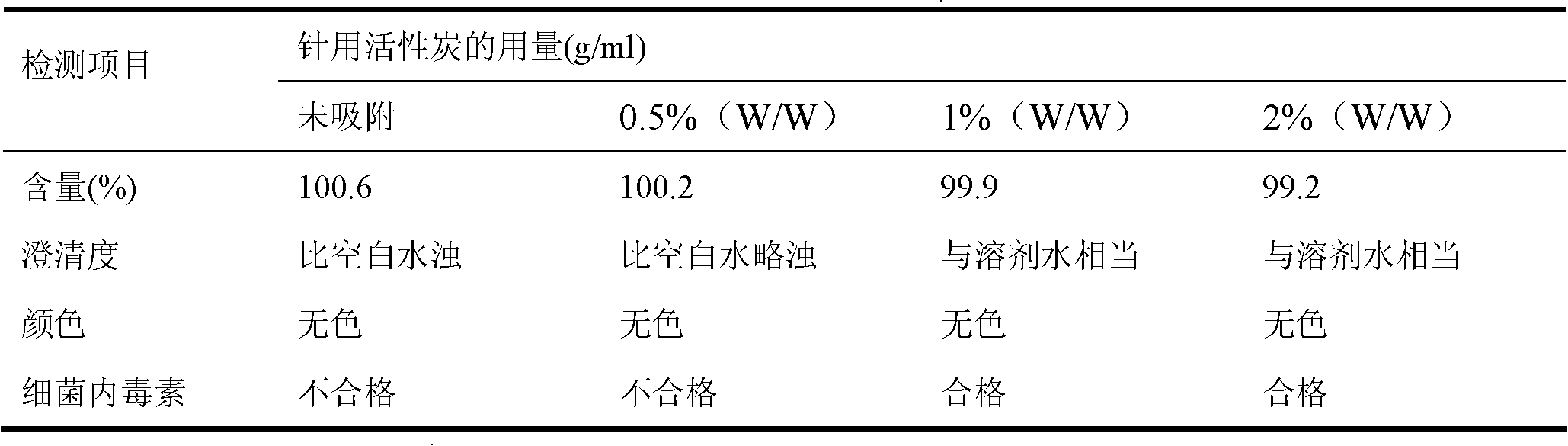

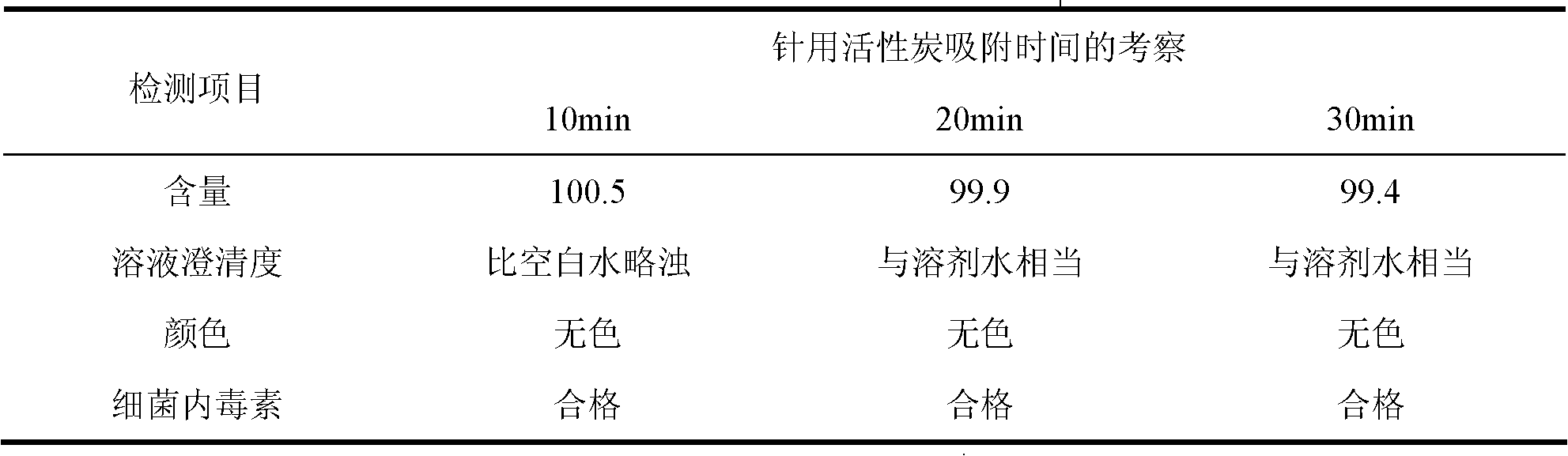

[0065] 1. Prepare the solution: prepare 6% dextran 20 solution with water for injection at a temperature of 10°C, add activated carbon for needles, stir, heat to 90°C for 30 minutes, and then decarbonize and filter through titanium rods; among them, add the mass percentage of activated carbon for needles The concentration is 2%;

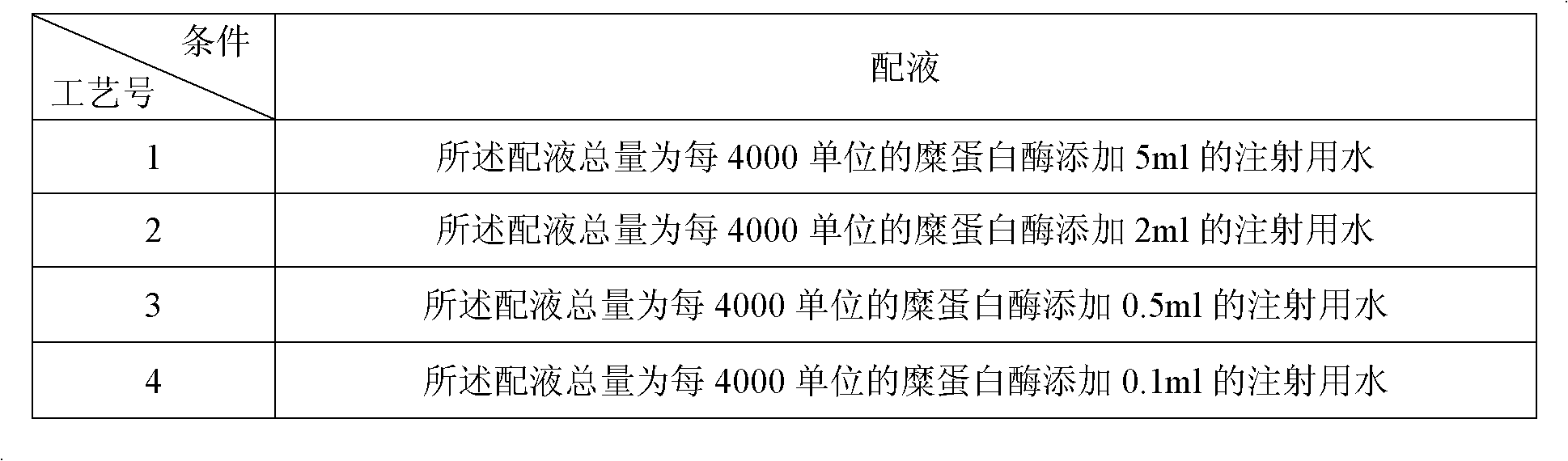

[0066] 2. Add water for injection with a temperature of 5°C and a volume of 60% of the total volume of the liquid in the liquid mixing tank, stir, add 6% dextran 20 solution, 20% sorbitol injection, and chymotrypsin in sequence, and stir until the chymotrypsin is completely Dissolve, add injection to the total amo...

Embodiment 2

[0076] A chymotrypsin composition freeze-dried powder, the formula is: chymotrypsin 40 million units; dextran 20:48g; sorbitol 6g.

[0077] The average porosity of the freeze-dried powder of the chymotrypsin composition is 95%.

[0078] The preparation method of described chymotrypsin composition freeze-dried powder comprises the steps:

[0079] 1. Prepare the solution: prepare 6% dextran 20 solution with water for injection at a temperature of 10°C, add activated carbon for needles, stir, heat to 90°C for 25 minutes, and then decarbonize and filter through titanium rods; among them, add the mass percentage of activated carbon for needles The concentration is 2%;

[0080] 2. Add water for injection with a temperature of 5°C and a volume of 60% of the total volume of the liquid in the liquid preparation tank, stir, then add 6% dextran 20 solution, 20% sorbitol injection, and chymotrypsin, and stir until the chymotrypsin is completely Dissolve and add injection to the total am...

Embodiment 3

[0090] A chymotrypsin composition freeze-dried powder, the formula is: chymotrypsin 40 million units; dextran 20: 56g: sorbitol 4g.

[0091] The average porosity of the freeze-dried powder of the chymotrypsin composition is 90-98%.

[0092] The preparation method of described chymotrypsin composition freeze-dried powder comprises the steps:

[0093] 1. Prepare the solution: prepare 6% dextran 20 solution with water for injection at a temperature of 10°C, add activated carbon for needles, stir, heat to 100°C for 15 minutes, filter and decarbonize; add activated carbon for needles with a concentration of 2% by mass;

[0094] 2. Add water for injection with a temperature of 10°C and a volume of 70% of the total volume of the liquid in the liquid preparation tank, stir, add 6% dextran 20 solution, 20% sorbitol injection, and chymotrypsin in turn, and stir until the chymotrypsin is completely Dissolve and add injection to the total amount of liquid; the total amount of liquid is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com