Intelligent control method of blast aeration system of municipal sewage plant

A blast aeration and intelligent control technology, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of not considering the coordinated control of valves and blowers, and the inability to ensure process safety and stability Operation, blower surge shutdown and other problems, to achieve the effect of saving aeration energy consumption, low cost, and safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

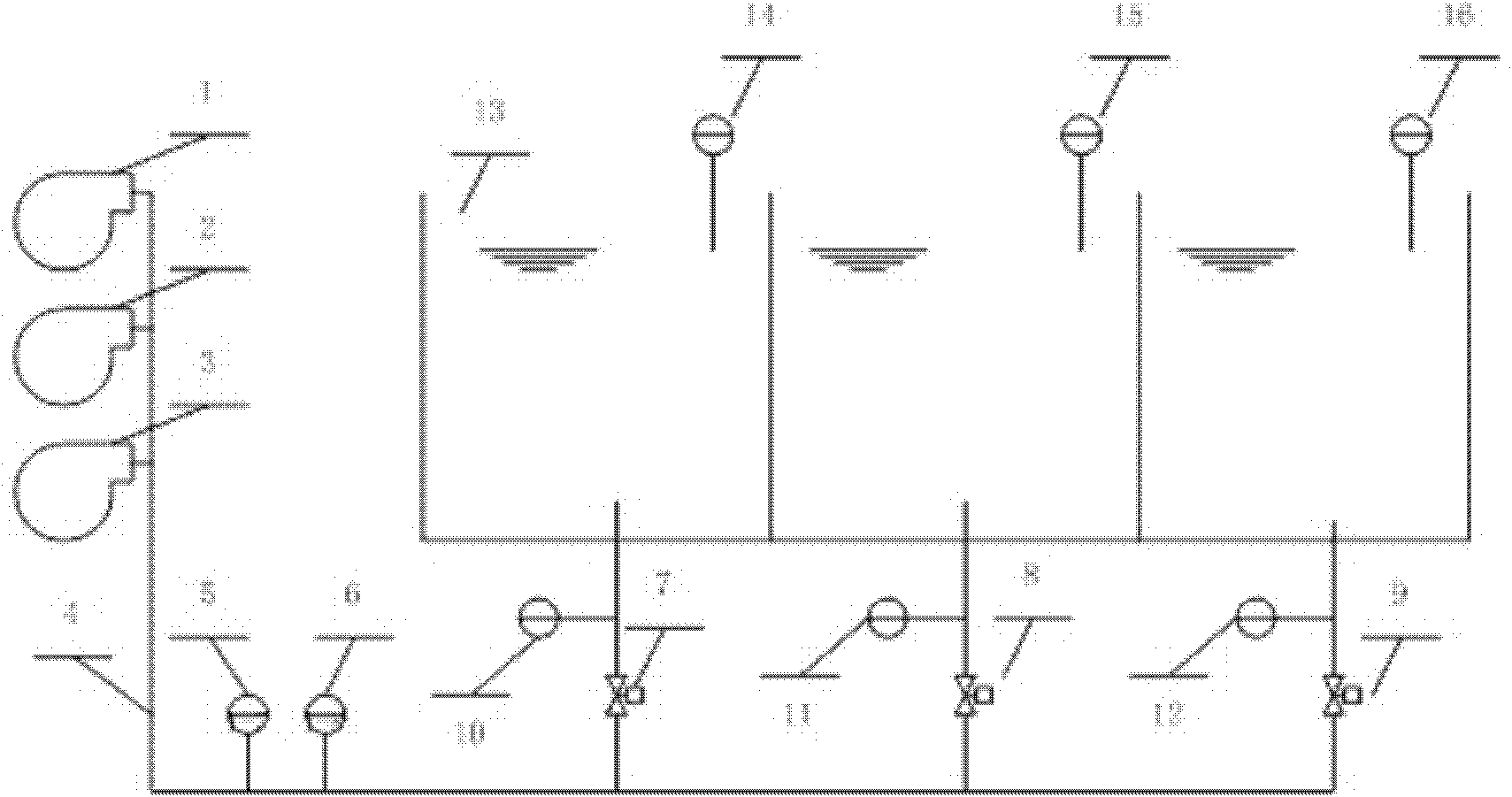

[0031] The invention takes the stability of dissolved oxygen in the aeration tank and the energy-saving operation of the blower aeration system as the control objectives, and focuses on solving the problems of precise control of the air supply volume and the coordinated control of the blower and each branch pipe valve when the water inflow load changes dynamically. The use of this method needs to be combined with the layout of on-site instrumentation equipment. The suitable layout diagram is as follows: figure 1 shown.

[0032] Such as figure 1 As shown, the blast aeration system of the present invention includes: an aeration tank 13, and the aeration tank is divided into several units (generally more than 2 sections, 3 in the present embodiment) along the direction of water flow; Dissolved oxygen detectors 14, 15, 16 for measuring the dissolved oxygen in the aeration tank 13 in the middle and back section of the tank; air blowers 1, 2, 3 for supplying air to the aeration tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com