Method for extracting catalpol from rehmannia stem

A technology of rehmannia glutinosa and catalpol, applied in the field of medicine, can solve the problems of cumbersome process, high production cost, and high process cost, and achieve the effects of overcoming technical prejudice, saving industrial cost, and reducing the amount of solvent used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

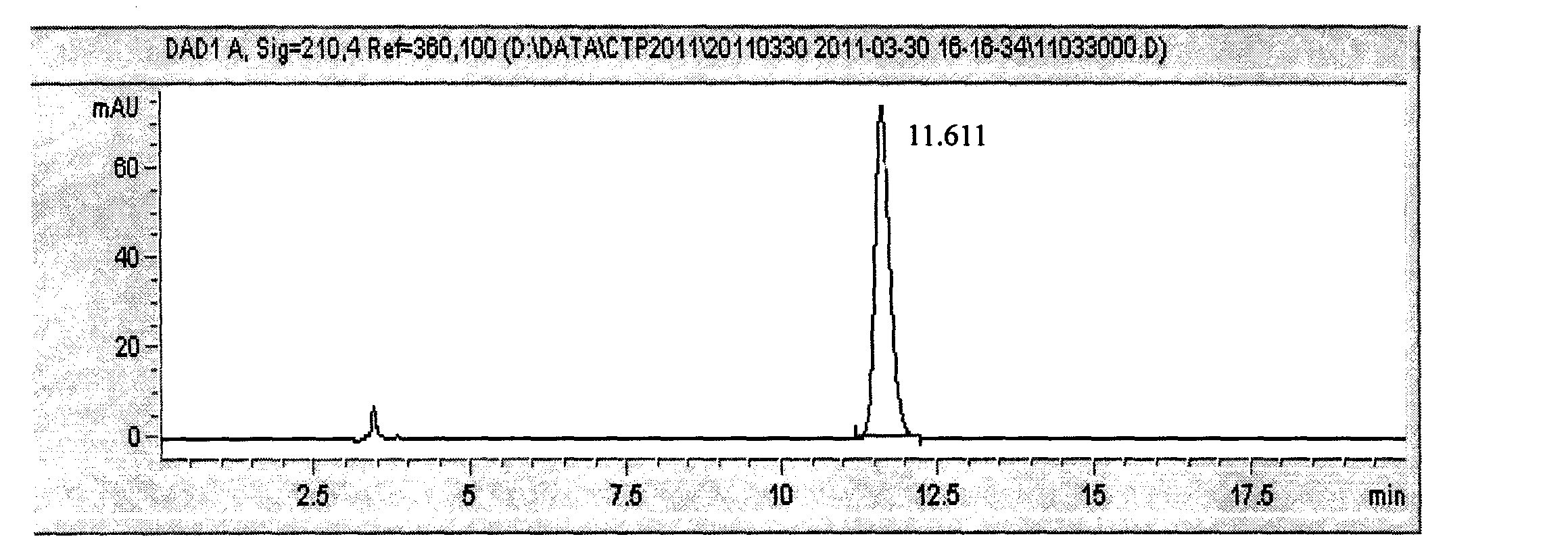

[0066] Take the rehmannia stem coarse powder, add 12 times the amount of water to 20.0 kg, extract under reflux for 2 times, 1 hour each time, combine the extracts, concentrate under reduced pressure to a relative density of 1.14 (50 ° C), add 95% by volume ratio 1:4 Ethanol was allowed to stand overnight, the supernatant was concentrated under reduced pressure to a relative density of 1.08 (50°C), the concentrated solution was allowed to cool, and an XAD-16 macroporous resin column was added (amount ratio of 1:4, diameter to height ratio of 1:10), First eluted with 2BV water, then eluted with 2.2BV of 6% ethanol, collected the 6% ethanol eluent, concentrated under reduced pressure to a thick paste, mixed with 50-100 mesh silica gel, evaporated to dryness, and added 100-200 mesh silica gel Column (amount ratio of 1:15), eluted with ethyl acetate / methanol 4:1, collected the target fraction, concentrated under reduced pressure, dried, the dried material was recrystallized with 85...

Embodiment 2

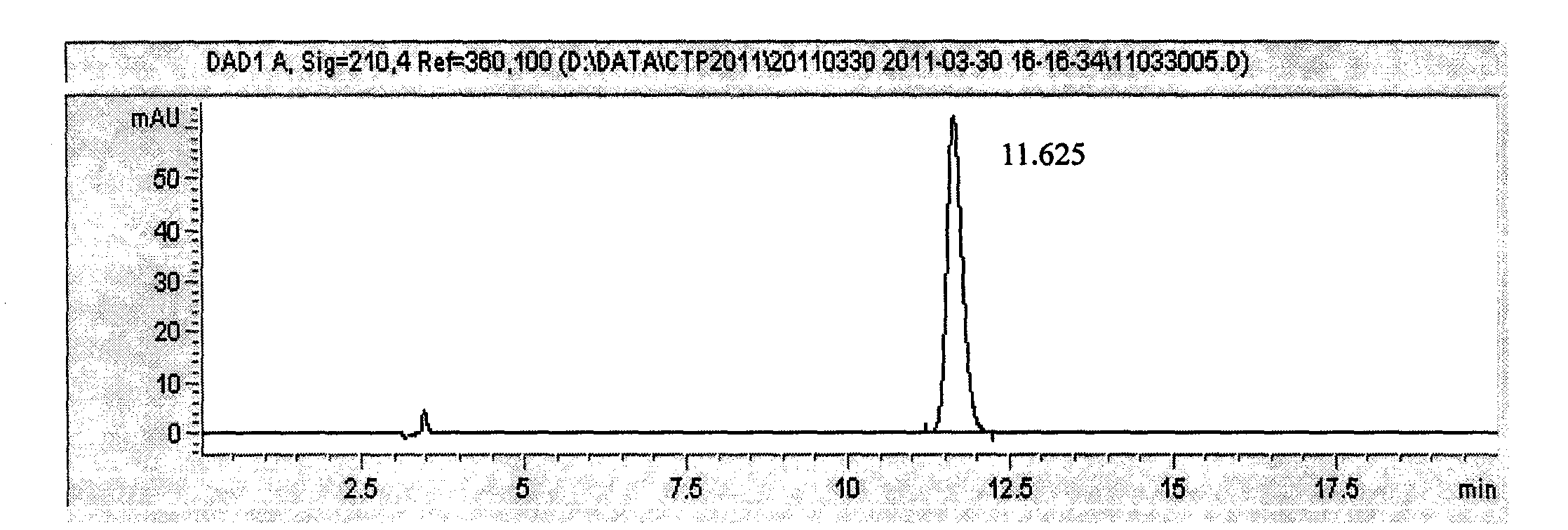

[0069] Take the rehmannia stem coarse powder, add 12 times the amount of water to 20.0 kg, extract under reflux for 2 times, 1 hour each time, combine the extracts, concentrate under reduced pressure to a relative density of 1.15 (50 ° C), add 100% by volume ratio 1:3 Ethanol, left standing overnight, the supernatant was concentrated under reduced pressure to a relative density of 1.13 (50°C), the concentrated solution was allowed to cool, and an XAD-16 macroporous resin column was added (amount ratio of 1:4, diameter to height ratio of 1:7), First eluted with 1BV water, then eluted with 3BV of 3% ethanol, collected the 3% ethanol eluent, concentrated under reduced pressure to a thick paste, mixed with 100-200 mesh silica gel, evaporated to dryness, and added a 100-200 mesh silica gel column (the dosage ratio is 1:20), eluted with ethyl acetate / methanol 5:1, collected the target fraction, concentrated under reduced pressure, dried, the dried material was recrystallized with 80%...

Embodiment 3

[0072] Take the rehmannia stem coarse powder, add 12 times the amount of water to 50kg, extract under reflux for 2 times, 1 hour each time, combine the extracts, concentrate under reduced pressure to a relative density of 1.16 (50°C), add 90% ethanol at a volume ratio of 1:5 , left standing overnight, the supernatant was concentrated under reduced pressure to a relative density of 1.10 (50°C), the concentrated solution was allowed to cool, and an XAD-16 macroporous resin column was added (amount ratio 1:4, diameter-height ratio 1:5), first Elute with 1.5BV water, then eluate with 1.5BV 10% ethanol, collect the 10% ethanol eluent, concentrate under reduced pressure to a thick paste, stir in 50-100 mesh silica gel, evaporate to dryness, add 50-100 mesh silica gel Column (amount ratio of 1:5), eluted with ethyl acetate / methanol 3:1, collected the target fraction, concentrated under reduced pressure, dried, the dried material was recrystallized with 95% ethanol, filtered and dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com