Lightweight polycarbonate composition and preparation method thereof

A technology of polycarbonate and composition, which is applied in the field of lightweight polycarbonate composition and its preparation, can solve the problems of complex preparation process and narrow application field, and achieve excellent mechanical properties, simple production process and light density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

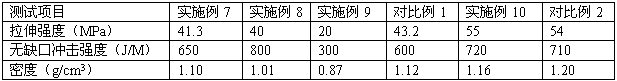

Examples

Embodiment 1

[0030] (1) Weigh each raw material according to the following parts by weight: PC-1 is 50, ABS8391 is 50, azodicarbonamide is 2, 2,6-tertiary butyl-4-resol is 1;

[0031] (2) After the above-mentioned raw materials are stirred and fully mixed in a medium-speed mixer for 20 minutes, they are fed into a twin-screw extruder with an aspect ratio of 32:1 through a metering device, and the temperature of the twin-screw extruder is controlled to be 180°C , the rotational speed of the twin-screw extruder is 600 rpm, the pressure is 2 MPa, the raw materials are melt extruded, and cooled in a die to form a lightweight polycarbonate composition.

Embodiment 2

[0033] (1) Weigh each raw material according to the following parts by weight: PC-1 is 90, ABS3453 is 10, barium azodicarboxylate is 1, and trioctyl phosphate is 0.1;

[0034] (2) After the above-mentioned raw materials are stirred and fully mixed in a medium-speed mixer for 20 minutes, they are fed into a twin-screw extruder with an aspect ratio of 45:1 through a metering device, and the temperature of the twin-screw extruder is controlled to be 300°C , the rotational speed of the twin-screw extruder is 400 rpm, and the pressure is 3 MPa.

Embodiment 3

[0036] (1) Weigh each raw material according to the following parts by weight: PC-2 is 70, ABS3504 is 30, high temperature expansion capsule foaming agent (AC foaming agent) is 1,2,6-tertiary butyl-4-methyl Grade phenol is 0.5, triisodecyl phosphite is 0.5;

[0037] (2) After the above-mentioned raw materials are stirred and fully mixed in a medium-speed mixer for 20 minutes, they are fed into a twin-screw extruder with a length-to-diameter ratio of 40:1 through a metering device, and the temperature of the twin-screw extruder is controlled to be 200°C , the speed of the twin-screw extruder is 200 rpm, the pressure is 2.5 MPa, the raw materials are melt-extruded, and cooled in a die to form a lightweight polycarbonate composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com