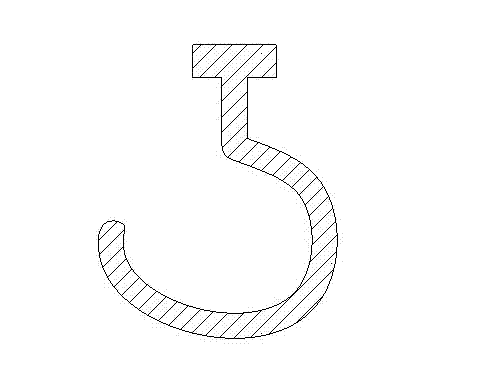

High-performance stainless steel hook

A stainless steel, high-performance technology, applied in the field of high-performance stainless steel hooks, stainless steel hooks, can solve the problems of insufficient strength, incapable of comprehensive promotion and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The specific preparation process of the preparation method of the high-performance stainless steel hook mentioned in the present invention is as follows:

[0019] a) Material selection and preparation. The main components and percentages of raw materials are: nickel powder 8%, chromium powder 6%, manganese powder 10%, molybdenum powder 4%, silicon powder 4%, refractory metal carbide 6%, increase Plasticizer is 6%, the rest is iron powder; the raw materials are ground and screened by a ball mill, and the particle size of nickel powder, chromium powder, manganese powder, molybdenum powder and silicon powder is about 300 meshes, and that of refractory metal carbides. It is 600 meshes, the iron powder particles are 200 meshes, and the carbon content in the iron powder is controlled at 0.6%-0.8%; the powder particles are roughly spherical; the plasticizer is chlorinated paraffin 70, and the particle size is about 100 mesh; WC powder is selected for refractory metal compound;

[...

Embodiment 2

[0025] The specific preparation process of the preparation method of the high-performance stainless steel hook mentioned in the present invention is as follows:

[0026] a) Material selection and preparation, the main components and percentages of raw materials are: nickel powder 9%, chromium powder 7%, manganese powder 8%, molybdenum powder 4%, silicon powder 5%, refractory metal carbide 7%, increase The plasticizer is 7%, and the rest is iron powder; the raw materials are ground and screened by a ball mill, and the obtained nickel powder, chromium powder, manganese powder, molybdenum powder and silicon powder have a particle size of about 350 meshes, and that of refractory metal carbides. It is 650 mesh, the iron powder particle is 250 mesh, the carbon content in the iron powder is controlled at 0.6%-0.7%; the powder particles are roughly spherical; the plasticizer is chlorinated paraffin 70, and the particle size is about 100 mesh; TiC powder is selected for refractory metal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com