Preparation method of hydrogen evolution electrode with high catalytic activity and high stability

A technology with high catalytic activity and high stability, applied in the direction of electrodes, electrode shapes/types, electrolytic components, etc., can solve the problems of high cost, low catalytic activity, poor stability, etc., and achieve low cost, good catalytic hydrogen evolution performance, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

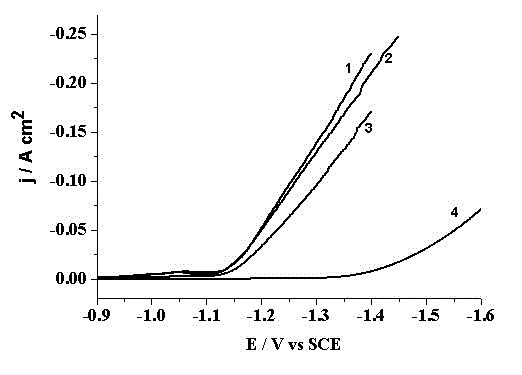

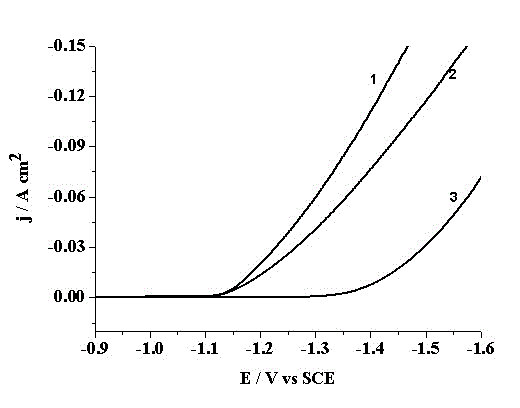

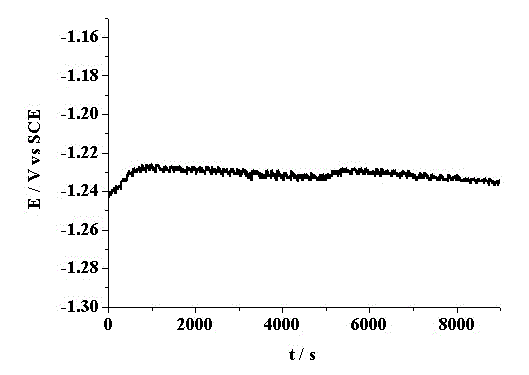

Examples

Embodiment 1

[0028] (1) Pretreatment of Ni substrate

[0029] First, mechanically polish the Ni sheet to remove oxides on the surface to make it metallic luster, and then clean it with ultrapure water; It is a mixed aqueous solution of 45g / L sodium sulfate, 45g / L sodium carbonate and 45g / L sodium chloride; then rinse it with deionized water, dry it naturally and immerse it in absolute ethanol solution for use;

[0030] (2) Preparation of Ni plating precursor electrode by pulse electroplating

[0031]A two-electrode system is adopted, the Ni substrate treated in step (1) is used as the working electrode, and the Ni plate is used as the counter electrode. The composition of the plating solution is: 40g / L nickel sulfate, 38.5 g / L sodium hypophosphite, 10g / L boric acid, 6g / L ammonium chloride, the pH value of the plating solution is 3, the temperature of the plating solution is 25°C, and the average current density is 40mA / cm 2 , the pulse frequency is 1000Hz, the duty ratio is 1:5, and the...

Embodiment 2

[0041] Step (1) is the same as step (1) in Example 1;

[0042] (2) Preparation of Ni-coated precursor electrode by pulse electroplating

[0043] A two-electrode system is adopted, the Ni substrate treated in step (1) is used as the working electrode, and the Ni plate is used as the counter electrode. The composition of the plating solution is: 20 g / L nickel sulfate, 60 g / L sodium hypophosphite, 10 g / L boric acid, 2 g / L ammonium chloride, the temperature of the plating solution is 20°C, and the average current density is 30 mA / cm 2 , the pulse frequency is 800Hz, the duty ratio is 1:4, and the plating time is 300s. Rinse with deionized water after electroplating to remove residual plating solution, and make Ni plating layer precursor electrode after natural air drying;

[0044] (3) Preparation of nickel-based Ni / RuO 2 Compound electrode

[0045] With n-butanol as solvent, RuCl 3 Dissolved in n-butanol to prepare 30mg / mL RuCl 3 The n-butanol solution was mixed evenly by ma...

Embodiment 3

[0049] Step (1) is the same as step (1) in Example 1;

[0050] (2) Preparation of Ni-coated precursor electrode by pulse electroplating

[0051] A two-electrode system is adopted, the Ni substrate treated in step (1) is used as the working electrode, and the Ni plate is used as the counter electrode. The composition of the plating solution is: 60g / L nickel sulfate, 20 g / L sodium hypophosphite, 5 g / L boric acid, 6 g / L ammonium chloride, the temperature of the plating solution is 25°C, and the average current density is 20 mA / cm 2 , the pulse frequency is 1200Hz, the duty ratio is 1:4, and the plating time is 300s. Rinse with deionized water after electroplating to remove residual plating solution, and make Ni plating layer precursor electrode after natural air drying;

[0052] (3) Preparation of nickel-based Ni / RuO 2 Compound electrode

[0053] With n-butanol as solvent, RuCl 3 Dissolved in n-butanol to prepare 10mg / mL RuCl 3 The n-butanol solution was mixed evenly by mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com