Molybdenum doped iron/nickel lamellar array @ nickel foam base composite electrode material and preparing method and application thereof

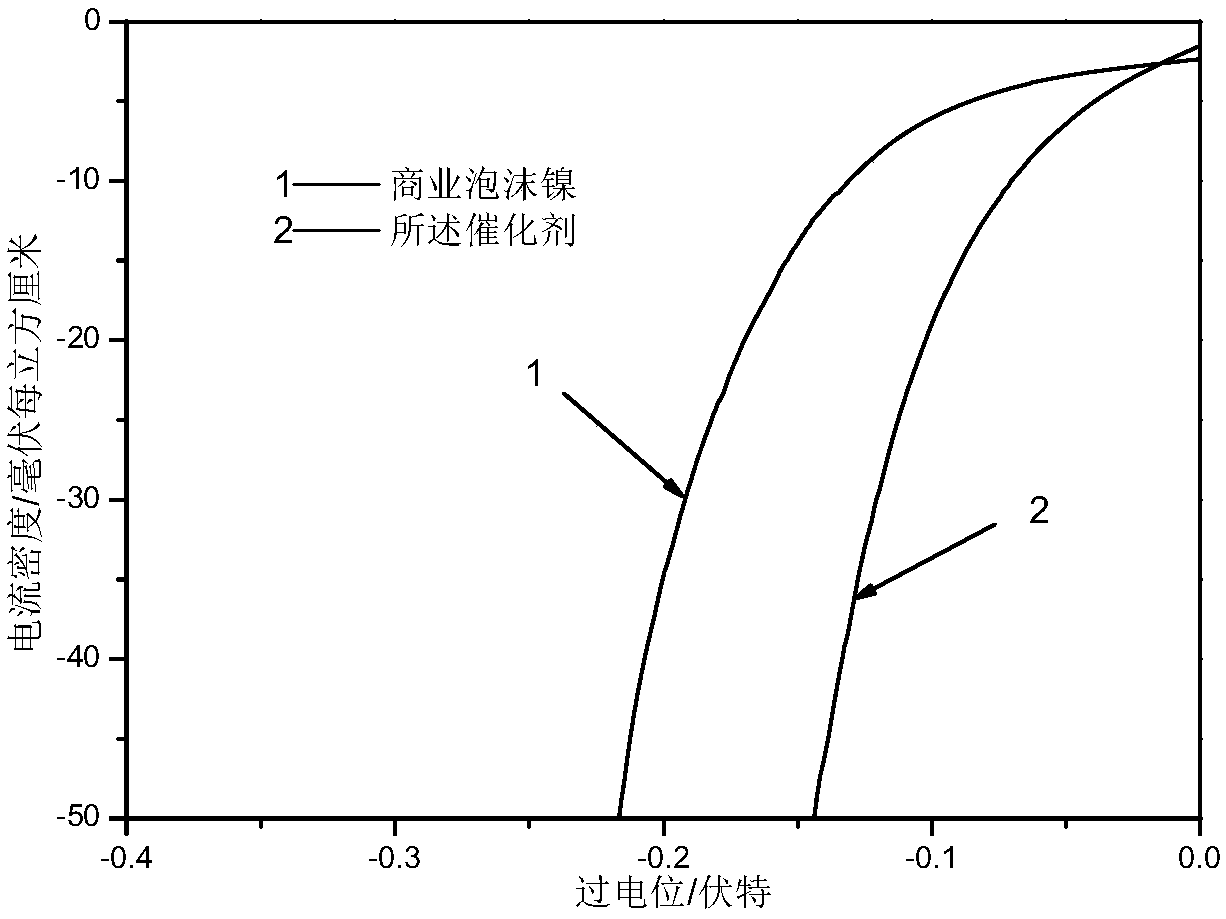

A composite electrode and nickel foam technology, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor catalyst stability, etc., and achieve the effects of good stability, low energy consumption, and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

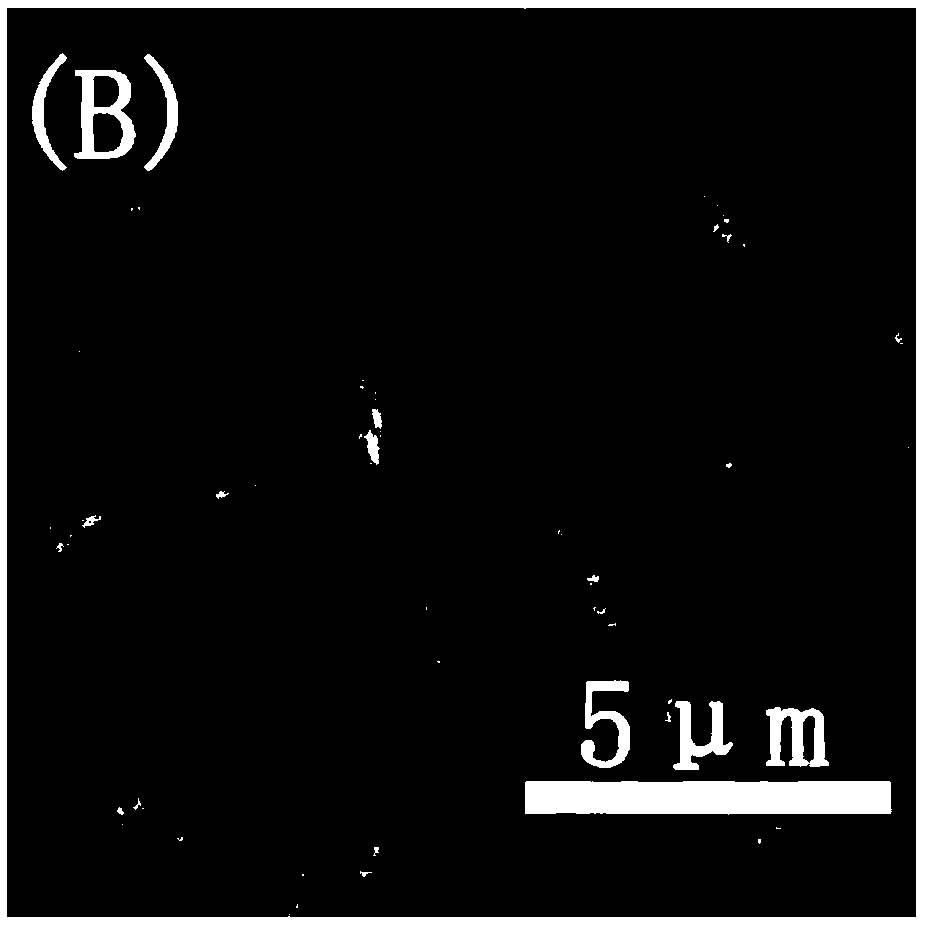

[0035] The molybdenum-doped iron / nickel layered array@foam nickel-based composite electrode material of the present invention specifically includes the following steps:

[0036] a. Take foam nickel, cut it into 1cm×3cm size, put it in a beaker, add absolute ethanol to submerge, pour out absolute ethanol after ultrasonication for 15min, add 1mol / L dilute hydrochloric acid until submerged, ultrasonication for 15min and then rinse with water spare;

[0037] b. Measure 20 mL of deionized water and place it in a conical flask, then add 0.45 g of ferric nitrate nonahydrate, 0.7 g of nickel nitrate hexahydrate, 0.7 g of ammonium fluoride, 0.05 g of polyethylene glycol (molecular weight: 6000), and urea 0.5g, stirred and ultrasonicated for 15min, until completely dissolved, placed in a 25mL high-temperature autoclave, added the nickel foam treated in step a, then raised the temperature to 120°C for 4h, separated, washed with water, and dried to obtain FeNi-LDHs Nickel Foam in Layered...

Embodiment 2

[0045] a. Take foam nickel, cut it into 1cm×3cm size, put it in a beaker, add absolute ethanol to submerge, pour out absolute ethanol after ultrasonication for 15min, add 1mol / L dilute hydrochloric acid until submerged, ultrasonication for 15min and then rinse with water spare;

[0046] b. Measure 20 mL of deionized water and place it in a conical flask, then add 0.5 g of ferric nitrate nonahydrate, 0.73 g of nickel nitrate hexahydrate, 0.72 g of ammonium fluoride, 0.1 g of polyethylene glycol (molecular weight: 6000), and urea 0.6g, stirred and ultrasonicated for 20min, until completely dissolved, placed in a 25mL high-temperature autoclave, added the nickel foam treated in step a, then raised the temperature to 150°C for 5h, separated, washed with water, and dried to obtain FeNi-LDHs@foam nickel.

[0047] c. Measure 20 mL of deionized water and place it in a conical flask, add 0.0247 g of ammonium heptamolybdate, and ultrasonicate until completely dissolved; immerse the FeN...

Embodiment 3

[0050] a. Take foam nickel, cut it into 1cm×3cm size, put it in a beaker, add absolute ethanol to submerge, pour out absolute ethanol after ultrasonication for 15min, add 1mol / L dilute hydrochloric acid until submerged, ultrasonication for 15min and then rinse with water spare;

[0051] b. Measure 20 mL of deionized water and place it in a conical flask, then add 0.55 g of ferric nitrate nonahydrate, 0.75 g of nickel nitrate hexahydrate, 0.75 g of ammonium fluoride, 0.15 g of polyethylene glycol (molecular weight: 6000), and urea 0.7g, stirred and ultrasonicated for 20min, until it was completely dissolved, placed in a 25mL high-temperature autoclave, added the nickel foam treated in step a, then raised the temperature to 100°C for 6h, and obtained FeNi-LDHs@foam after separation, washing and drying nickel.

[0052] c. Measure 20 mL of deionized water and place it in a conical flask, add 0.0247 g of ammonium heptamolybdate, and ultrasonicate until it is completely dissolved; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com