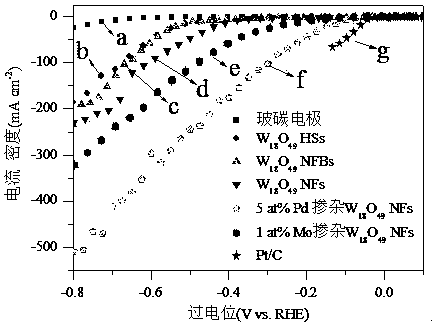

A metal-doped W18O49 electrocatalyst with multiple morphologies and its application in water electrolysis for hydrogen production

A W18O49, metal doping technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, electrolytic components, etc., can solve the problems of low catalytic activity, high cost, and poor stability of hydrogen evolution catalysts , to achieve the effect of good catalytic hydrogen evolution performance, good conductivity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] One, W described in the present invention 18 o 49 The preparation method of NFs electrocatalyst specifically comprises the following steps:

[0033] 1. Mix 0.1 g WCl 6Dissolve in 50 mL of absolute ethanol to form a yellow clear liquid with a mass volume ratio of 2 mg / mL;

[0034] 2. Transfer the yellow clear liquid to a 60 mL stainless steel reaction kettle lined with polytetrafluoroethylene, and then seal it;

[0035] 3. Heat the reaction kettle in an oven at 180°C for 24 h, then cool it down to room temperature naturally;

[0036] 4. The product obtained after centrifuging the obtained reaction solution was washed with distilled water and absolute ethanol for 3 times each;

[0037] 5. Dry the washed product in a vacuum oven at 45°C for 12 h to obtain W 18 o 49 NFs electrocatalyst.

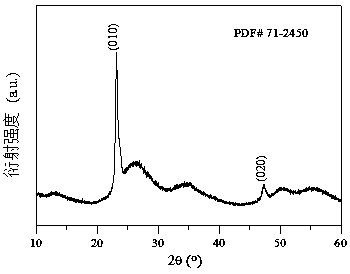

[0038] Two, W 18 o 49 Characterization of physical properties of NFs

[0039] Test the W prepared by the above steps respectively 18 o 49 XRD and SEM of NFs, the test resul...

Embodiment 2

[0053] One, the present invention W 18 o 49 The preparation method of NFBs electrocatalyst specifically comprises the following steps:

[0054] 1. Mix 0.17 g WCl 6 Dissolve in 50 mL of absolute ethanol to form a yellow clear liquid with a mass volume ratio of 3.4 mg / mL;

[0055] 2. Transfer the yellow clear liquid to a 60 mL stainless steel reaction kettle lined with polytetrafluoroethylene, and then seal it;

[0056] 3. Heat the reaction kettle in an oven at 180°C for 24 h, then cool it down to room temperature naturally;

[0057] 4. The product obtained after centrifuging the obtained reaction solution was washed with distilled water and absolute ethanol for 3 times each;

[0058] 5. Dry the washed product in a vacuum oven at 45°C for 12 h to obtain W 18 o 49 NFBs electrocatalyst.

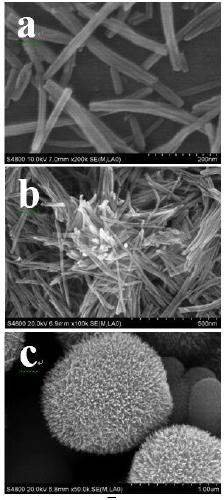

[0059] Two, W 18 o 49 Characterization of physical properties of NFBs

[0060] Test the W prepared by the above steps 18 o 49 SEM of NFBs electrocatalyst, the test results are as ...

Embodiment 3

[0067] One, the present invention W 18 o 49 The preparation method of HSs electrocatalyst specifically comprises the following steps:

[0068] 1. Mix 0.5 g WCl 6 Dissolve in 50 mL of absolute ethanol to form a yellow clear liquid with a mass volume ratio of 10 mg / mL;

[0069] 2. Transfer the yellow clear liquid to a 60 mL stainless steel reaction kettle lined with polytetrafluoroethylene, and then seal it;

[0070] 3. Heat the reaction kettle in an oven at 180°C for 24 h, then cool it down to room temperature naturally;

[0071] 4. The product obtained after centrifuging the obtained reaction solution was washed with distilled water and absolute ethanol for 3 times each;

[0072] 5. Dry the washed product in a vacuum oven at 45°C for 12 h to obtain W 18 o49 HSs electrocatalyst.

[0073] Two, W 18 o 49 Characterization of physical properties of HSs

[0074] Test the W prepared by the above steps 18 o 49 SEM of HSs electrocatalyst, the test results are as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com