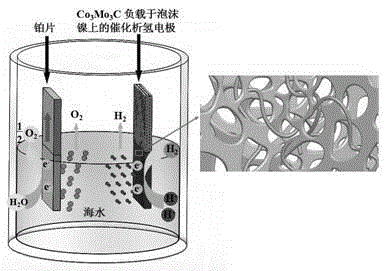

Novel Co3Mo3C electro-catalyst and application of novel Co3Mo3C electro-catalyst in hydrogen production through sea water electrolyzing

An electrocatalyst, seawater technology, applied in the electrolysis process, electrolysis components, electrodes and other directions, can solve the problems of high cost, low catalytic activity of hydrogen evolution electrode, poor stability, etc., and achieve good electrical conductivity, superior electrocatalytic activity, The effect of the preparation method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] One, the novel Co with high catalytic activity and high stability described in the present invention 3 Mo 3 The preparation method of C electrocatalyst specifically comprises the following steps:

[0042] 1. Dissolve ammonium molybdate tetrahydrate, cobalt acetate tetrahydrate and hexamethylenetetramine in a molar ratio of 7:1:37 in ammonia water with a mass fraction of 15%, and the obtained magenta solution is stirred and evaporated at room temperature , until a magenta slurry is obtained;

[0043] 2. Put the magenta slurry into a vacuum drying oven, dry it at 60°C for 12 hours, and grind it into powder;

[0044] 3. Put the powder into a tube furnace, feed it with Ar (99.99%), raise it to 750°C at a rate of 5°C / min, keep it at this temperature for 2 hours, and then cool it naturally to obtain Co 3 Mo 3 C electrocatalyst.

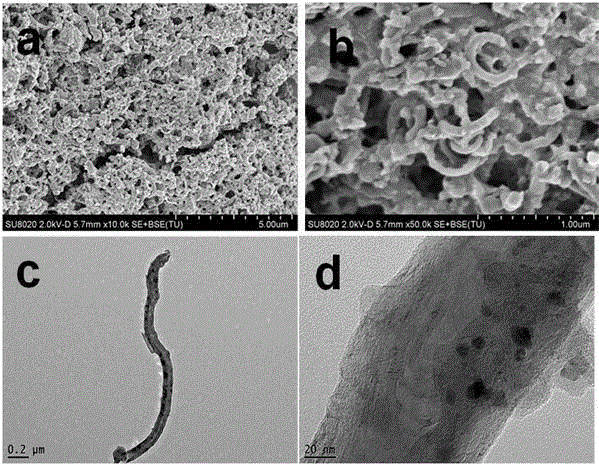

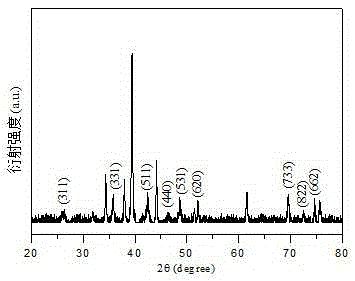

[0045] Two, Co 3 Mo 3 Characterization of Physical Properties of C Electrocatalysts

[0046] Test the Co prepared by the above steps separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com