Oxygenated fuel

An oxygen-containing fuel and carbon oxidation technology, applied in the direction of liquid carbon-containing fuel, waste fuel, biofuel, etc., can solve the problem of large additional costs of catalytic reactors, achieve the effect of eliminating carbon dioxide and hydrocarbon emissions, and improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

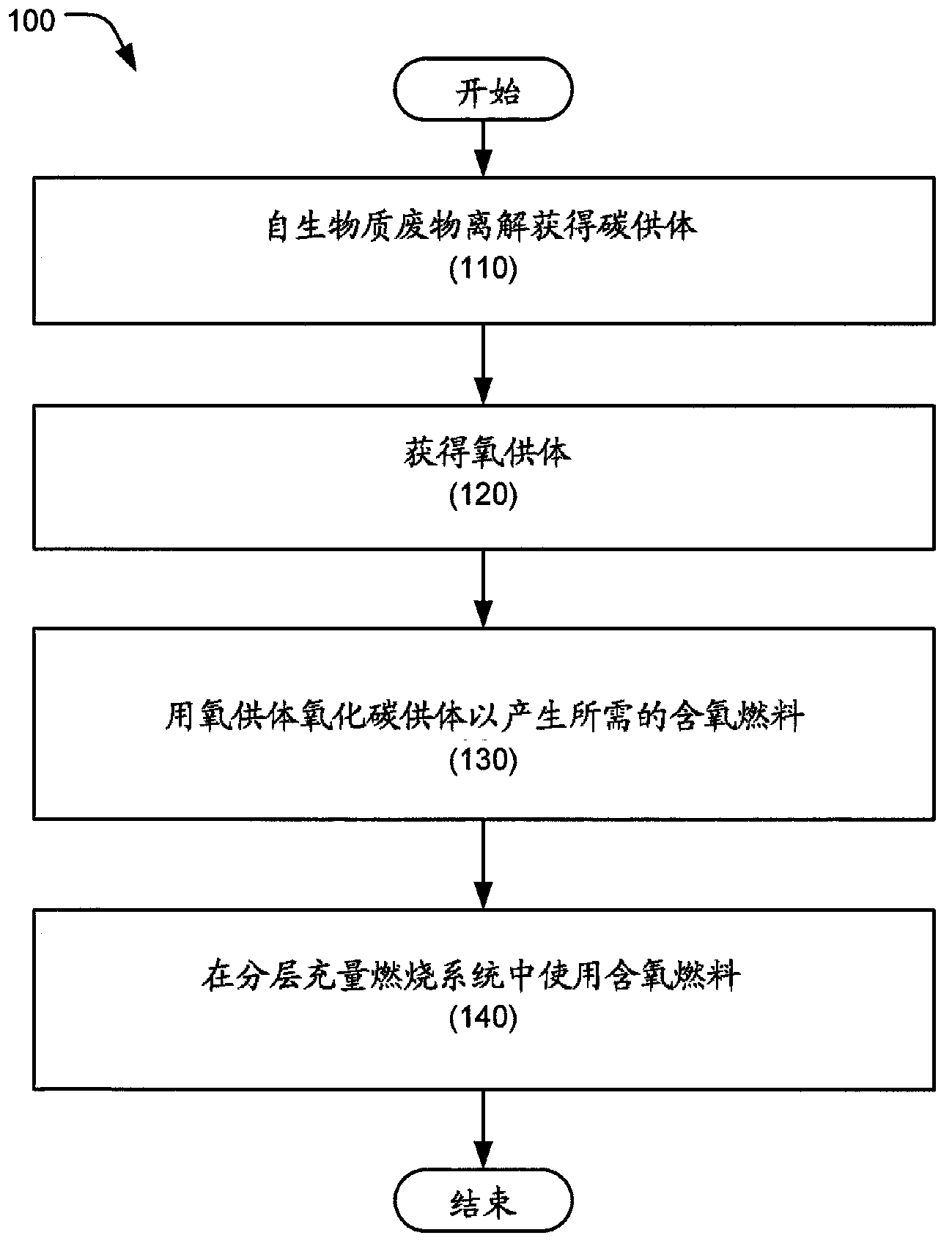

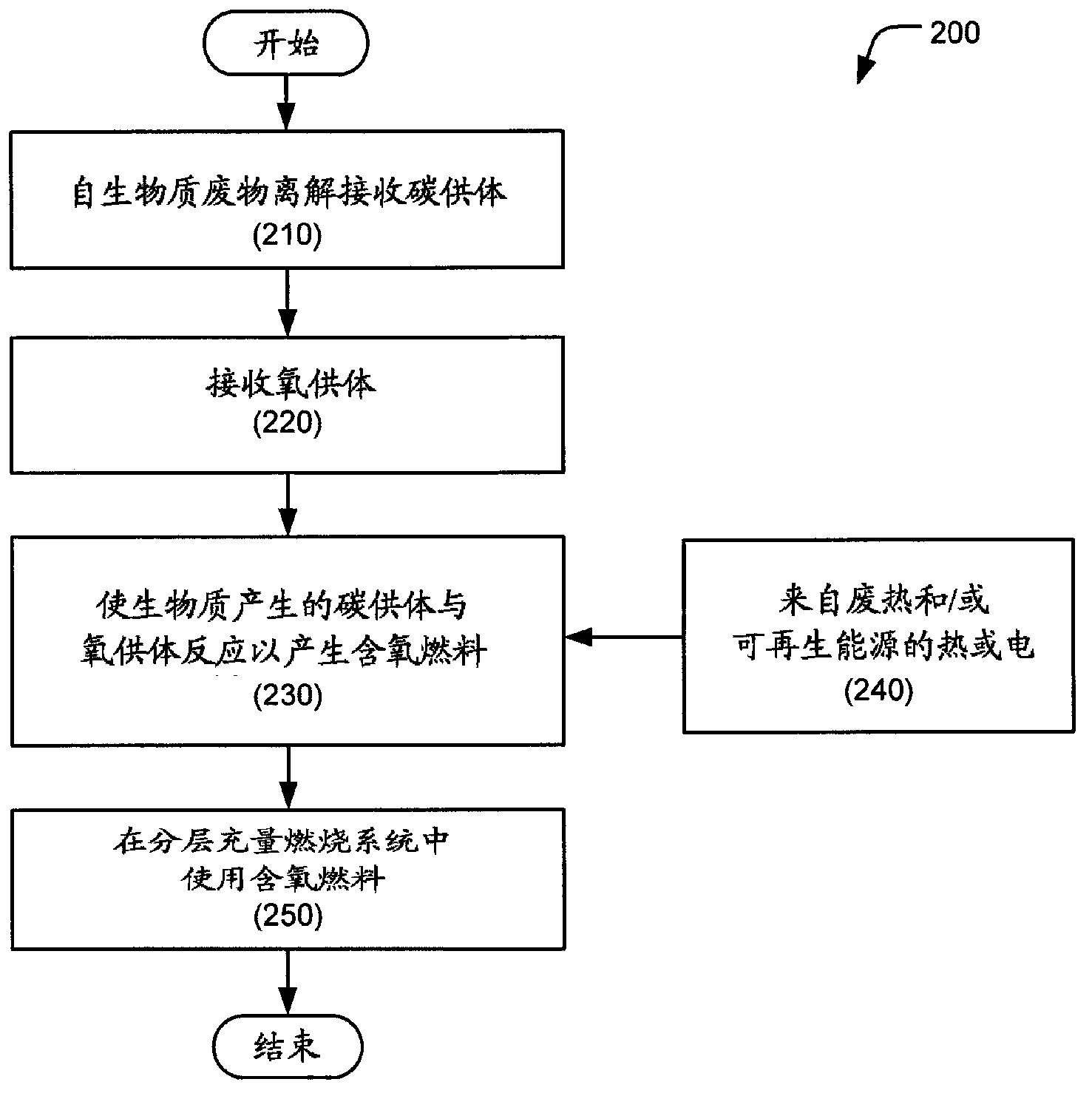

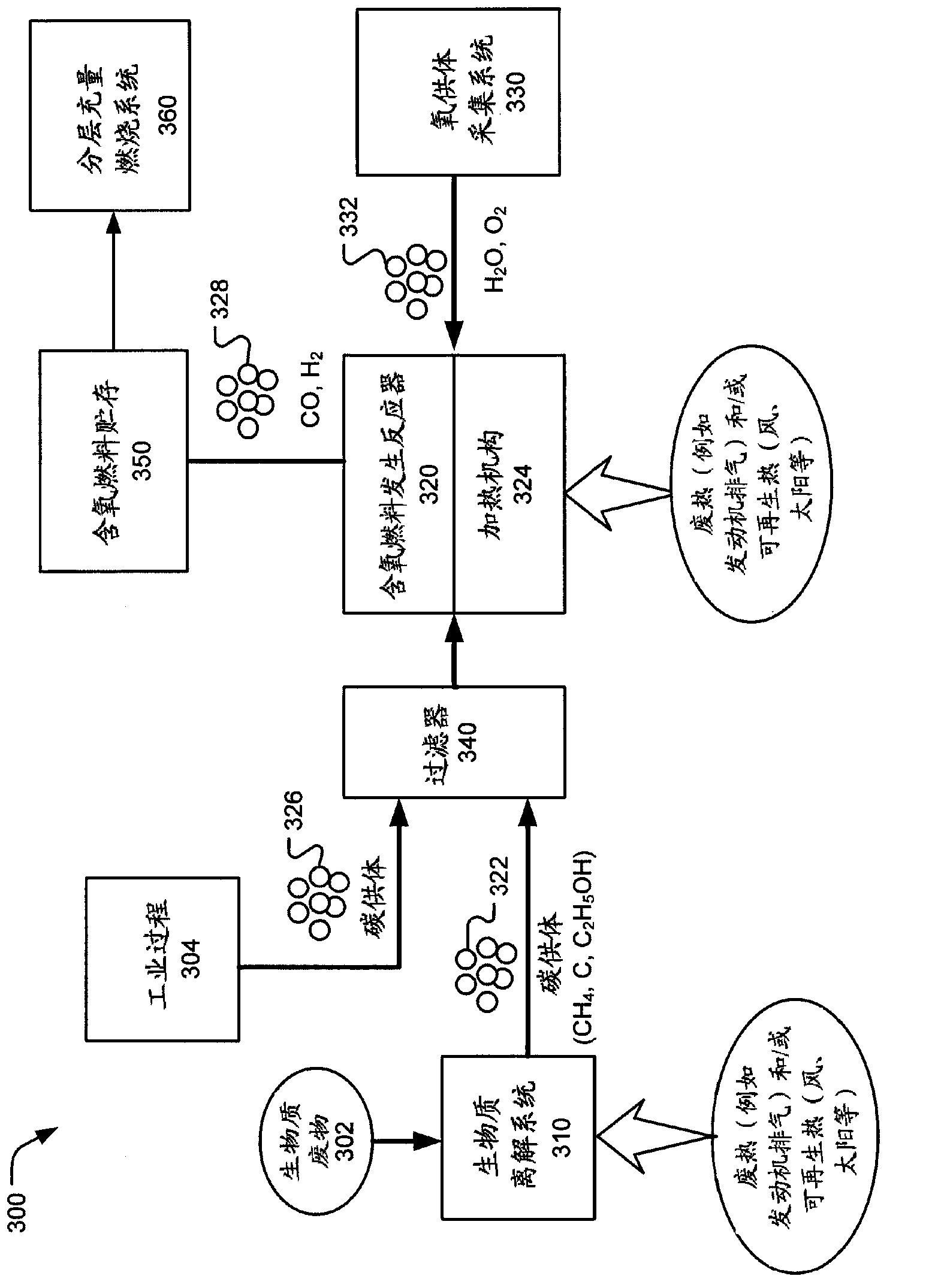

Method used

Image

Examples

Embodiment Construction

[0026] Ignition delay for conventional diesel fuel made from a mixture of large molecules as liquid fuel components includes the time to vaporize and crack these molecules and then penetrate enough additional hot air to ignite. Small gaseous molecules such as hydrogen (H 2 ) and carbon monoxide (CO) delays are much shorter and eliminate particle formation. The time to complete combustion of any fuel is related to the heat required to vaporize and crack the fuel, the availability of oxidant, the heat released by combustion, and the degree to which the heat release is conserved. To equalize kinetic energy in a population of mixed molecules, small molecules have much higher velocities than large molecules. At the same temperature, small molecules such as hydrogen travel faster, traverse greater distances, collide more frequently, and diffuse faster than larger molecules. Hydrogen burns over a much wider range of air-fuel ratios than most hydrocarbons. This, combined with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com