Method for preparing ultralow cement artificial fishing reef concrete by waste concrete

A technology of waste concrete and artificial fish reef, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems that do not involve the utilization of waste concrete and seawater wet-drained fly ash, and achieve the reduction of preparation Cost, improvement of ecological environment, effect of improving pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

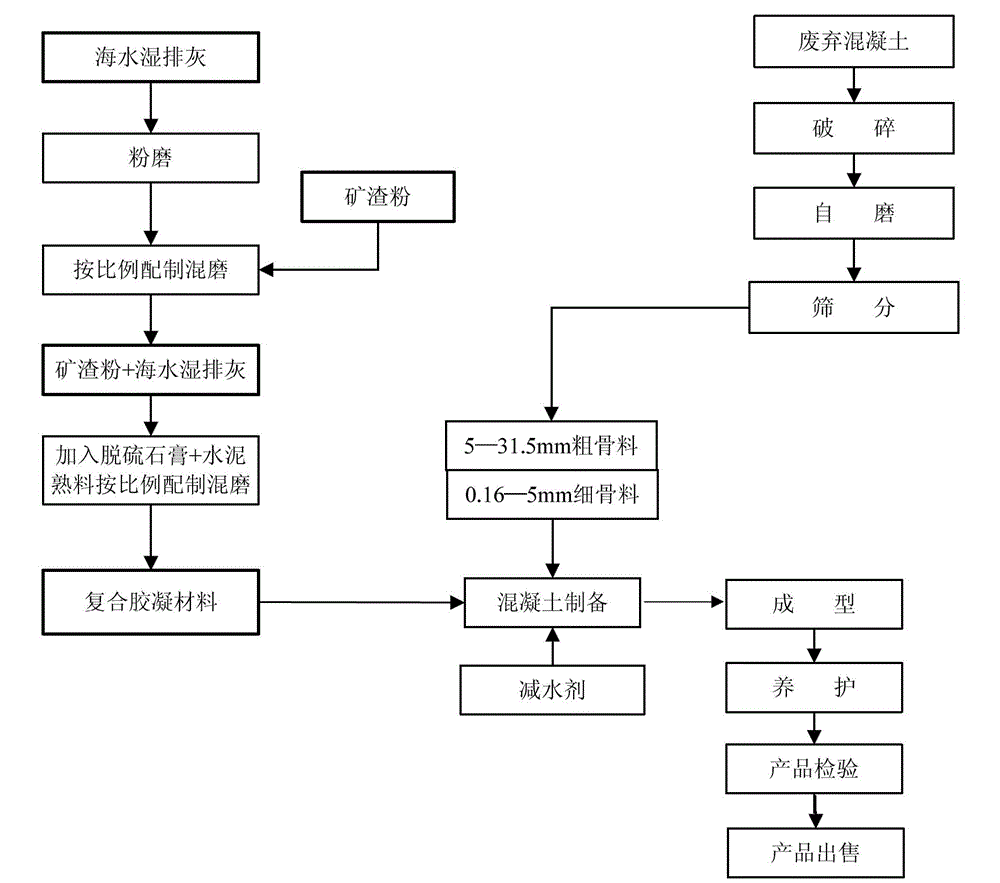

[0028] Step 1. Use cascade grinding, first dry the seawater wet ash to a moisture content of ≤1%, and then grind it until the specific surface area is 604m 2 / kg, adding a specific surface area of 408m 2 / kg of slag powder, mixed with clinker and desulfurized gypsum dried to a moisture content of ≤1% to a specific surface area of 520m 2 / kg to obtain the gelled material. Among them, slag powder, seawater wet discharge fly ash, cement clinker, and desulfurized gypsum are 65%: 15%: 10%: 10% on a dry basis.

[0029] Step 2. Crushing, self-grinding and sieving the waste concrete to obtain coarse aggregate with a particle size in the range of 5-31.5 mm and fine aggregate with a particle size in the range of 0.16-5 mm.

[0030] Step 3. The specific surface area obtained in step 1 is 408 m 2 / kg cementitious material and the recycled coarse aggregate with a particle size within the range of 5-31.5mm and the recycled fine aggregate with a particle size within the range of 0.16-...

Embodiment 2

[0033] Step 1. Use cascade grinding, first dry the seawater wet ash to a moisture content of ≤1%, and then grind it until the specific surface area is 604m 2 / kg, adding a specific surface area of 408m 2 / kg of slag powder, mixed with clinker and desulfurized gypsum dried to a moisture content of ≤1% to a specific surface area of 520m 2 / kg to obtain the gelled material. Among them, slag powder, seawater wet discharge fly ash, cement clinker, and desulfurized gypsum are 65%: 15%: 10%: 10% on a dry basis.

[0034] Step 2. Crushing, self-grinding and sieving the waste concrete to obtain coarse aggregate with a particle size in the range of 5-31.5 mm and fine aggregate with a particle size in the range of 0.16-5 mm.

[0035] Step 3. The specific surface area obtained in step 1 is 408 m 2 / kg cementitious material and the recycled coarse aggregate with a particle size within the range of 5-31.5mm and the recycled fine aggregate with a particle size within the range of 0.16-...

Embodiment 3

[0038] Step 1. Use cascade grinding, first dry the seawater wet ash to a moisture content of ≤1%, and then grind it until the specific surface area is 604m 2 / kg, adding a specific surface area of 408 m 2 / kg of slag powder, mixed with clinker and desulfurized gypsum dried to a moisture content of ≤1% to a specific surface area of 507m 2 / kg to obtain the gelled material. Among them, slag powder, seawater wet discharge fly ash, cement clinker, and desulfurized gypsum are in a mass ratio of 40%: 40%: 10%: 10%.

[0039] Step 2. Crushing, self-grinding and sieving the waste concrete to obtain coarse aggregate with a particle size in the range of 5-31.5 mm and fine aggregate with a particle size in the range of 0.16-5 mm.

[0040] Step 3. The specific surface area obtained in step 1 is 408 m 2 / kg cementitious material and the recycled coarse aggregate with a particle size within the range of 5-31.5mm and the recycled fine aggregate with a particle size within the range of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com