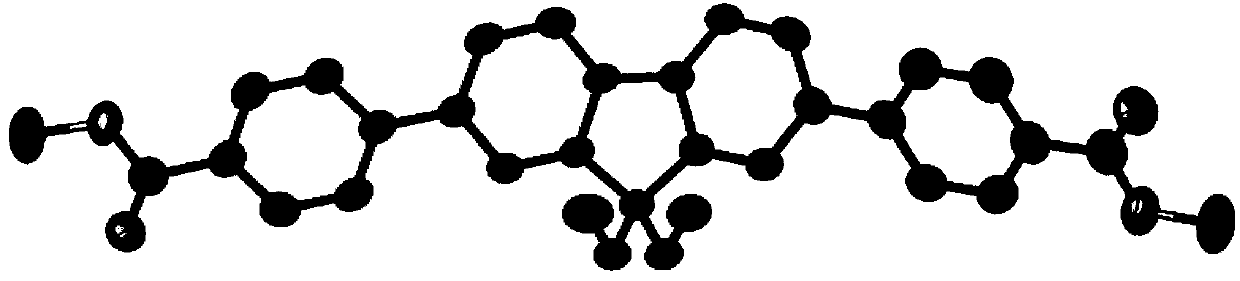

Fluorene acid ester fluorescent material and preparation method thereof

A fluorescent material, fluorene carboxylate technology, applied in organic chemistry and other directions, can solve problems such as harsh preparation conditions, and achieve the effects of not harsh synthesis conditions, low equipment cost, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

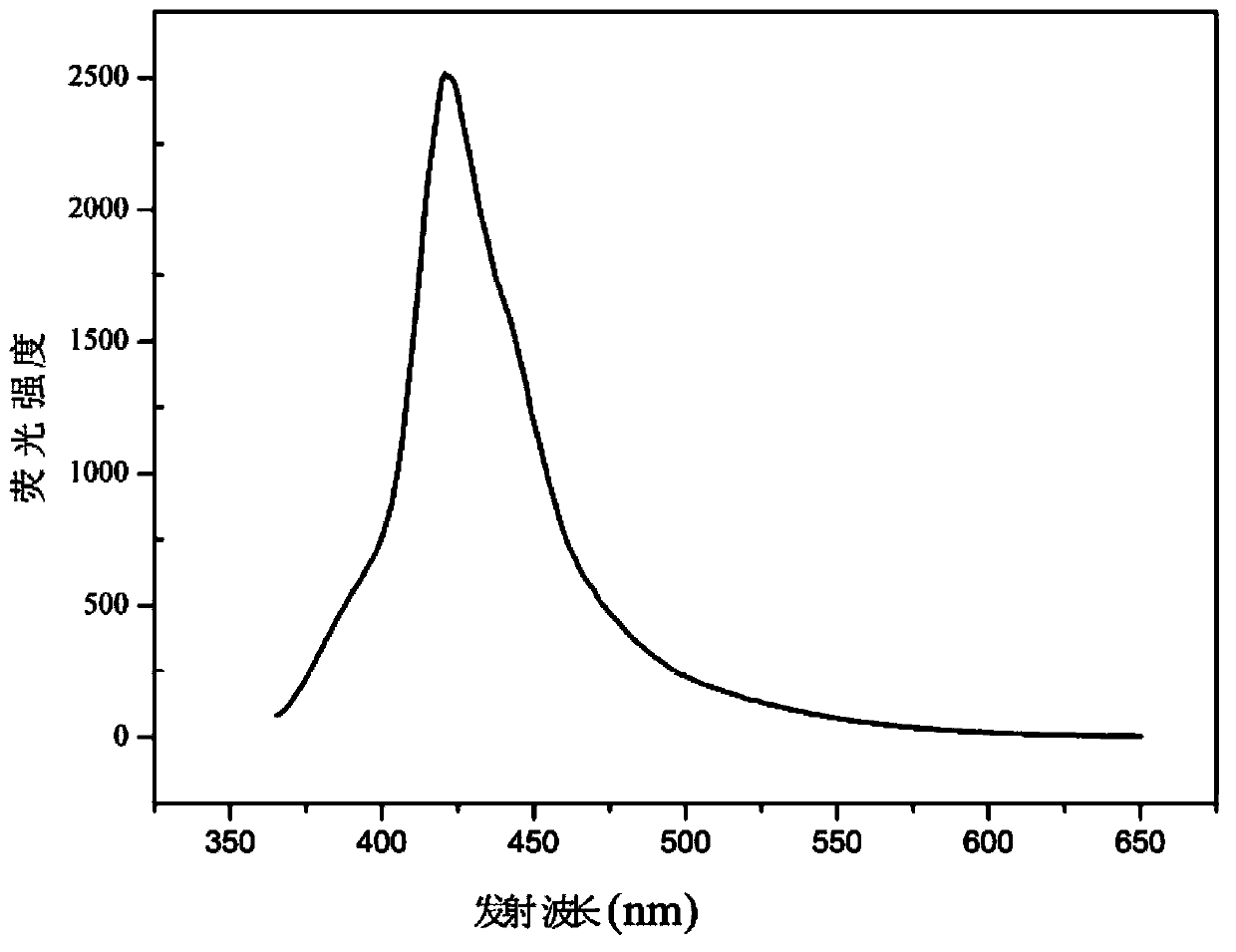

Embodiment 1

[0020] Take solid powder material 9,9-diethyl-2,7-dibromofluorene (1.29g, 4mmol), 4-methoxycarbonylphenylboronic acid (1.62g, 9mmol), tetrakistriphenylphosphine palladium (0.300g, 0.26mmol), potassium carbonate (2.07g, 15mmol) were mixed in a 250ml three-necked flask; the three-necked flask was evacuated and filled with nitrogen for 3 times; then injected with 50ml of toluene, 25ml of ethanol and 10ml of water The mixed solution was reacted at 80°C for 2 days under the protection of nitrogen, and the reaction process was tracked by thin-layer chromatography during the reaction; after the reaction was completed and the reaction solution was cooled, the aqueous phase was extracted with dichloromethane, and then washed with saturated brine to remove impurities , then dried with anhydrous magnesium sulfate, filtered; spin-dried toluene, ethanol and dichloromethane in the filtrate to obtain a solid mixture, the mixed solvent of petroleum ether and ethyl acetate with a volume ratio o...

Embodiment 2

[0022] Take solid powder material 9,9-diethyl-2,7-dibromofluorene (1.29g, 4mmol), 4-methoxycarbonylphenylboronic acid (2.16g, 12mmol), tetrakistriphenylphosphine palladium (0.185g, 0.16mmol), potassium carbonate (2.77g, 20mmol) were mixed in a 250ml three-necked flask; the three-necked flask was evacuated and filled with nitrogen 4 times; then a mixture of 60ml of toluene, 25ml of ethanol and 15ml of water was injected into the deoxygenated 20min Liquid, reacted at 85°C for 2 days under the protection of nitrogen, and tracked the reaction process with thin-layer chromatography during the reaction; after the reaction was completed and the reaction liquid was cooled, the aqueous phase was extracted with dichloromethane, and then washed with saturated brine to remove impurities. Dry with anhydrous magnesium sulfate afterwards, filter; Spin-dry the toluene in the filtrate, ethanol and methylene dichloride to obtain solid mixture after, with the mixed solvent that sherwood oil and e...

Embodiment 3

[0024] Take solid powder material 9,9-diethyl-2,7-dibromofluorene (1.61g, 5mmol), 4-methoxycarbonylphenylboronic acid (3.24g, 18mmol), tetrakistriphenylphosphine palladium (0.462g, 0.40mmol), potassium carbonate (4.15g, 30mmol) were mixed in a 250ml three-necked flask; the three-necked flask was evacuated and filled with nitrogen for 3 times; then a mixture of 90ml of toluene, 50ml of ethanol and 30ml of water was injected for 25min in addition to peroxygen liquid, reacted at 95°C for 3 days under the protection of nitrogen, and tracked the reaction process with thin-layer chromatography during the reaction; after the reaction was completed and the reaction liquid was cooled, the aqueous phase was extracted with dichloromethane, and then washed with saturated brine to remove impurities. Dry with anhydrous magnesium sulfate afterwards, filter; Spin-dry the toluene in the filtrate, ethanol and methylene dichloride to obtain solid mixture after, with the mixed solvent that sherwoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com