High-efficiency bioflocculant producing bacterium, screening method thereof and application of high-efficiency bioflocculant producing bacterium in treatment of sulfamethoxazole

A bioflocculant, sulfamethoxazole technology, applied in the field of high-efficiency bioflocculant producing bacteria, can solve the problems of low removal ratio, frequent detection, etc., to reduce production energy consumption, good removal ability, increase production and flocculation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1, a high-efficiency bioflocculant-producing bacterium is Klebsiella MFX ( Klebsiella sp.), was deposited on June 20, 2012 in the "General Microbiology Center of China Committee for the Collection of Microorganisms", and its preservation number is CGMCC NO. 6243.

[0023] Its screening method is:

[0024] (1) Take 15 mL of fresh activated sludge from Harbin Taiping Sewage Treatment Plant and add it to 100 mL of YP liquid basal medium in a triangular flask, and place it in a shaker with a temperature of 30 °C and a rotation speed of 150 r / min for 18~ After 48 h, the enriched bacterial solution was obtained;

[0025] (2) Take 15mL of the enriched bacteria solution and add it to a 100mL YP liquid basal medium conical flask, repeat the culture conditions of step (1) 3 to 4 times to obtain the acclimatized bacteria solution;

[0026] (3) Gradual dilution of the domesticated bacteria solution, the dilution gradient is 10 -1 、10 -2 、10 -3 、10 -4 、10 -5 、10 ...

Embodiment 2

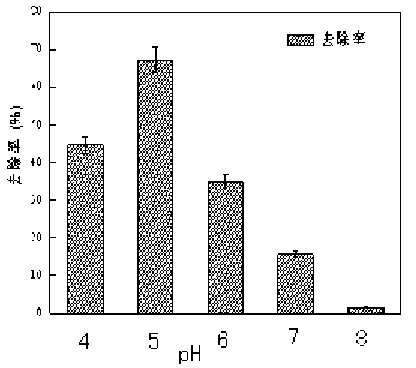

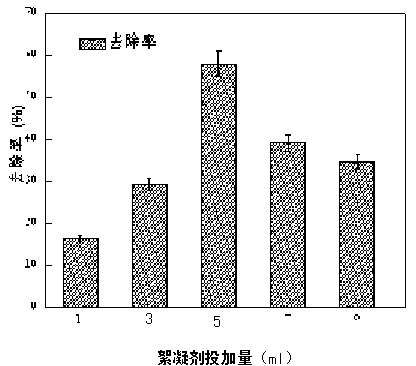

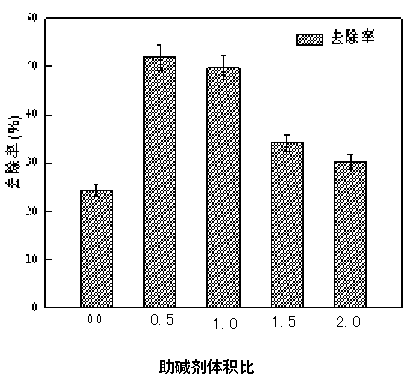

[0032]In Example 2, the dry powder of the biological flocculant produced by the fermentation of the strains in Example 1 was dissolved in distilled water to prepare a 2 g / L aqueous solution and put it into 1 mg / L sulfamethoxazole sewage. Methods The dosage of flocculant was 1mL, 3mL, 5mL, 7mL and 9mL; the dosage of coagulant aid CaCl2 solution was 0 mL, 0.5 mL, 1 mL, 1.5 mL and 2 mL; 6, 7, 8; the temperature was set to 5°C, 15°C, 25°C, 35°C, 45°C, 55°C, the rotation speed of the shaker was 140 r / min, and the reaction was 0 h, 0.25 h, 0.5 h, 0.75 h, 1 h, 2 h, 4 h, 6 h, 8 h, 10 h, 12 h, the results are as follows Figure 1-Figure 5 As shown, the optimal removal conditions are as follows: pH value is 5, flocculant dosage is 5 mL, coagulation aid dosage is 0.5 mL, flocculation time is 1 h, and temperature is 35 °C. Under these conditions, the removal effect of sulfamethoxazole solution is good, and the removal rate can reach 67.82%.

[0033] To treat the actual domestic sewage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com