Method of balancing pressure for well cementation

A technology of balancing pressure and cementing, which is applied in the field of oil and gas well cementing, and achieves the effect of wide applicable formation range, prevention of pressure leakage, and low risk of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments.

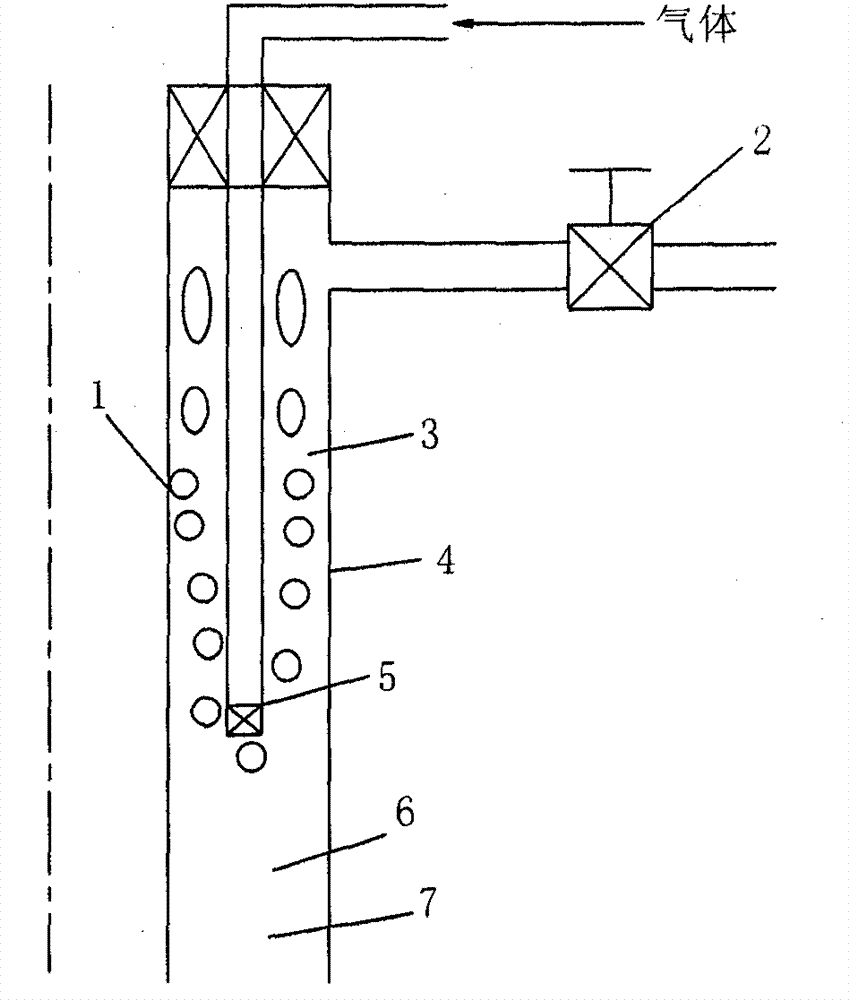

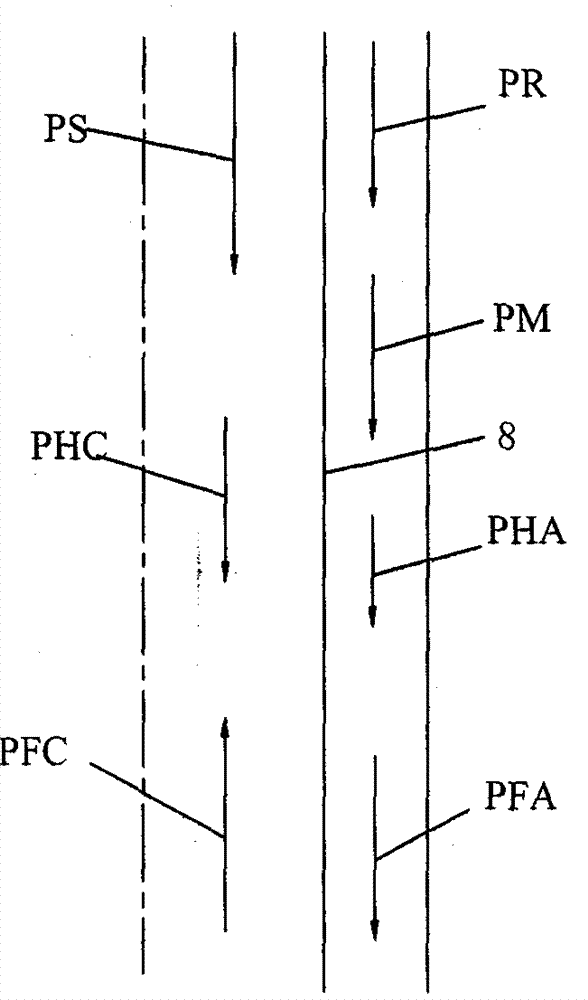

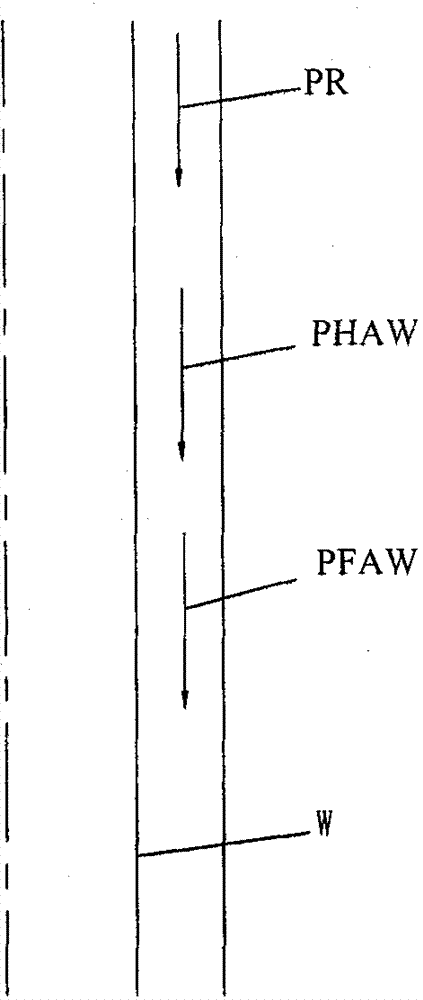

[0022] The principle of the present invention is as figure 1 (the vertical dotted line in the figure is the shaft centerline, the same below). A gas injection pipe connected with a check valve 5 at the lower end is lowered into the annular space 7 between the casing 1 and the well wall 4, and the gas-liquid two-phase flow is formed in the annular space above the gas injection point through gas injection, thereby The annulus pressure of the wellbore above the gas injection point is reduced, and the annulus below the gas injection point still adopts the conventional pad fluid and conventional density cement slurry system. During the gas injection process, as the cement slurry returns upward in the annular space, the gas gradually returns upward in the annular space. Due to the gradual decrease in the density of the drilling fluid mixed with the gas, a negative pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com