Deep hole pre-grouting top plate reinforcement method for large-mining height working face under special geological conditions

A special geological and working face technology, applied in underground chambers, mining equipment, earthwork drilling and mining, etc., can solve the problems of high polymer shallow grouting cost, poor effect, accidents and disasters of personnel and equipment, and achieve reinforcement Good effect, avoid downhole accidents, reasonable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The large mining height working face of 4210 main lane of Changping Coal Industry Company revealed the collapsed column (special geology). In order to ensure the smooth passage of the mining face, the top of the collapsed column needs to be reinforced by grouting. According to the site survey, the collapsed column is an elliptical long axis 65 meters, the short axis is 21 meters, and the axial direction is 38°. The collapse column does not contain water, and the north-south influence range in the working face is 57 meters, and the east-west influence range is 42 meters.

[0020] The affected area of the collapse column is 57m long. Considering the high pressure on the roof after mining, the grouting reinforcement sections extending 15 m on both sides of the collapse column were exposed in the roadway, and the total grouting reinforcement section was 87m.

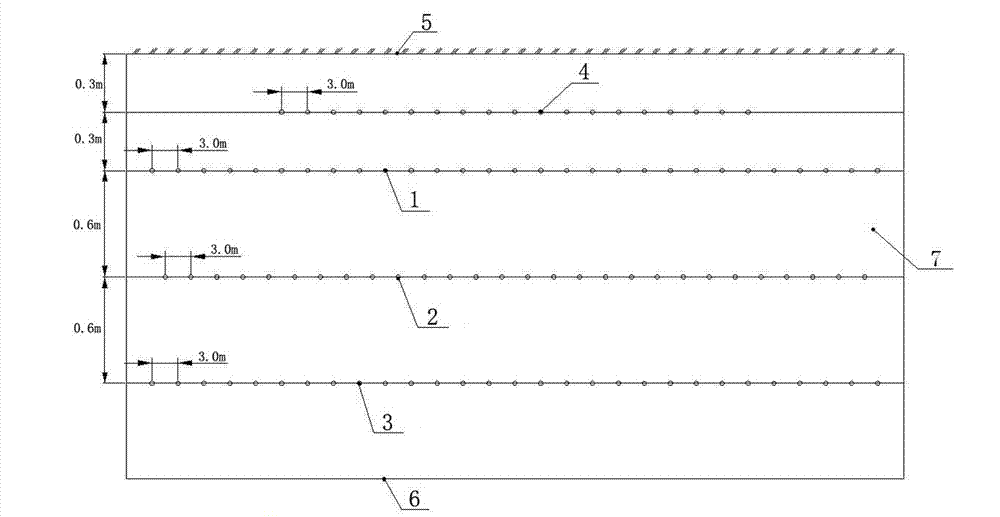

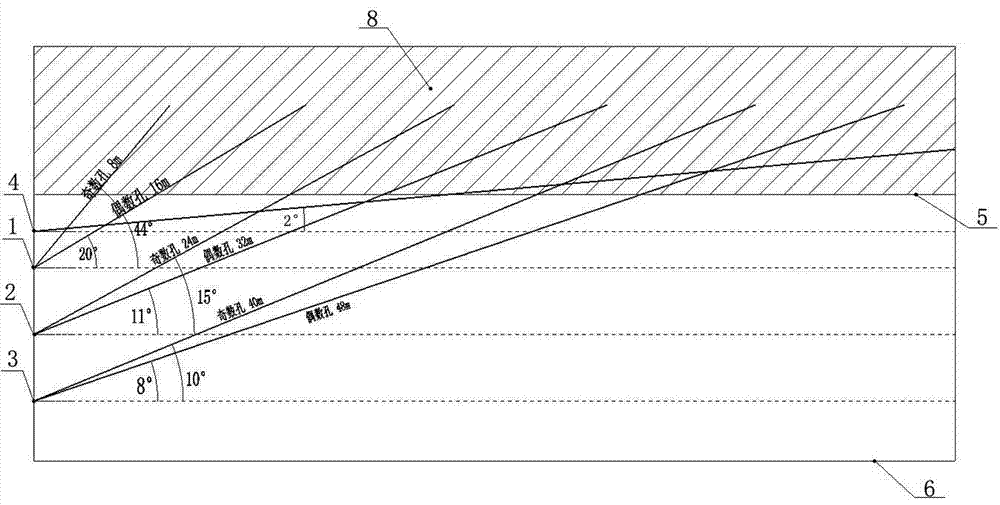

[0021] The grouting reinforcement of the collapsed column of the working face is carried out below by the method o...

Embodiment 2

[0027] A fault (special geology) was found in the large mining height working face of a mine. In order to ensure the smooth passage of the mining face, the top of the fault needs to be reinforced by grouting. According to the on-site survey, the fault has a north-south influence range of 72 meters and an east-west influence range of 53 meters in the working face .

[0028]The length of the working face affected by the fault is 72m. Considering the high roof pressure after mining, the grouting reinforcement section extending 15m on both sides of the fault is exposed in the roadway, and the total grouting reinforcement section is 102m.

[0029] Carry out grouting reinforcement to this working face fault by the method of the present invention below, specifically comprise the following steps:

[0030] 1) It is determined that the influence range of the fault in the large mining height working face is 102m, and then arrange three rows of drill holes from top to bottom on the side o...

Embodiment 3

[0035] A soft coal area (special geology) was found in the large mining height working face of a mine. In order to ensure the smooth passage of the mining face, grouting was required to reinforce the top of the soft coal area. According to the on-site survey, the soft coal area has a north-south influence range of 32 meters in the working face , the east-west influence range is 19 meters.

[0036] The length of the working face affected by the soft coal area is 32m. Considering the high roof pressure after mining, the grouting reinforcement sections extending 10 m on both sides of the soft coal area are exposed in the roadway, and the total grouting reinforcement section is 52m.

[0037] Carry out grouting reinforcement by the soft coal area of this working face below by the inventive method, specifically comprise the following steps:

[0038] 1) Determine that the influence range of the soft coal area in the large mining height working face is 102m, and then arrange three r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com