Test analysis method for manufactured super-diffraction directional transmission material structure

A technology of directional transmission and material structure, which is applied in the field of testing and analysis after the preparation of super-diffractive directional transmission material structures, can solve the problems of difficult operation, low efficiency, and inability to reveal the super-diffractive optical properties of materials, so as to achieve less external interference and test analysis. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

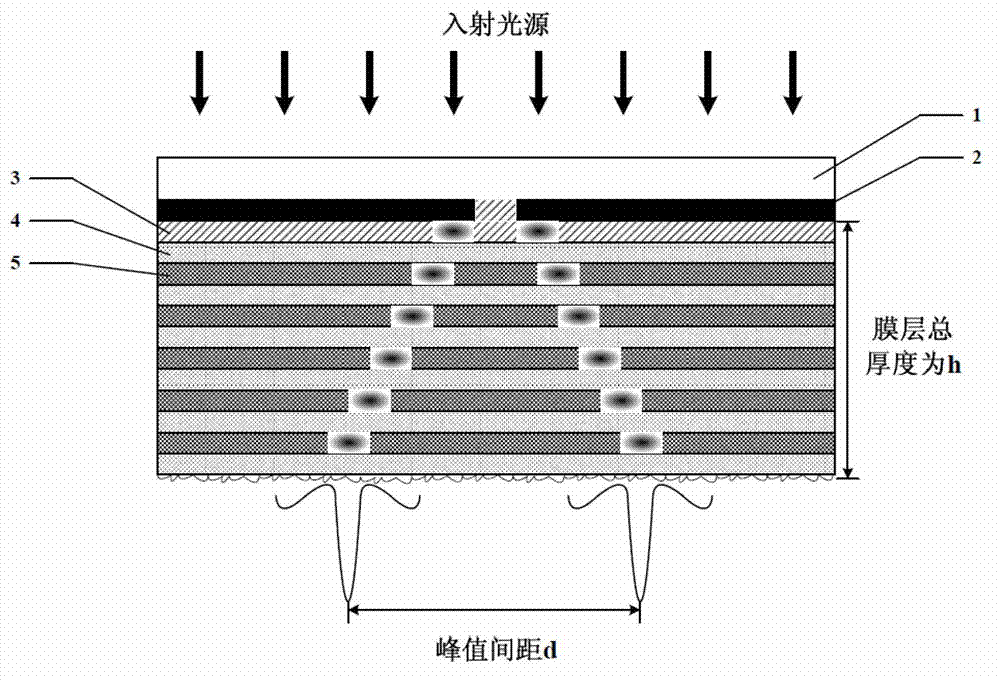

[0026] Embodiment 1, utilize the present invention to realize Ag / SiO 2 Structural preparation and test analysis of superdiffraction material with directional transmission angle of 70.2°.

[0027] (1) Choose double-sided finely polished quartz glass with a diameter of 25.4mm as the transparent substrate, and use nanofabrication on this transparent substrate to obtain a single-slit structure Cr mask with a slit width of 80nm, and the thickness of the Cr mask is 40nm;

[0028] (2) The planarization of the nano-single-slit mask was realized by spin-coating PMMA, and the thickness of the PMMA planarization layer was controlled at 20nm by reactive ion etching, the etching power was 5W, and the etching gas was O 2 , the etching gas flow rate is 10SCCM;

[0029] (3) Then deposit Ag / SiO on the planarized nano single-slit mask by surface electron beam evaporation deposition method 2 Super-diffraction multi-layer film material, the number of Ag layers is 8 layers, SiO 2 The number of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com