Wet type sample gas analyzing system applicable to monitoring of combustion conditions of coal-fired kilns

A technology of gas analysis system and combustion status, which is applied in the direction of analysis materials, preparation of test samples, and measurement devices, etc. Continuous and other issues, to achieve the effect of less maintenance, simple structure, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

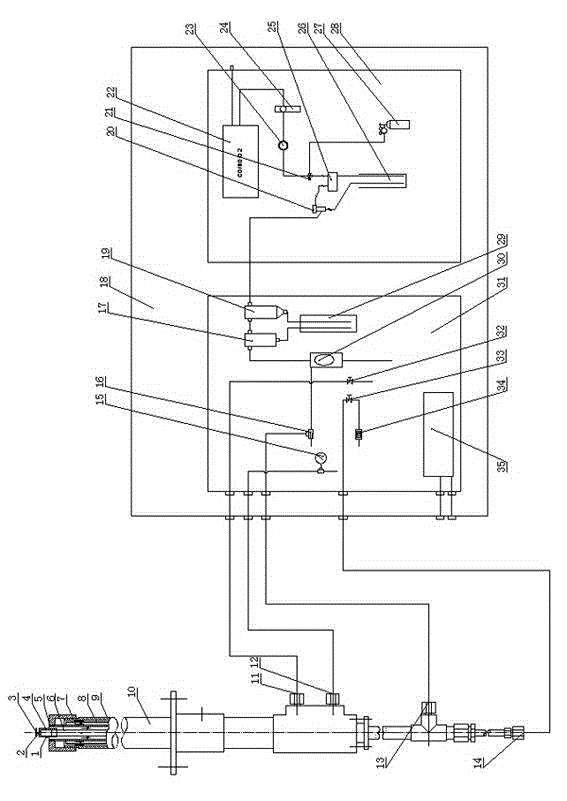

[0029] This embodiment is a wet sampling gas analysis system suitable for monitoring the combustion status of a coal-fired kiln. This system is composed of a sampling probe 25, an analysis cabinet 22, a pretreatment cabinet 23, and the like.

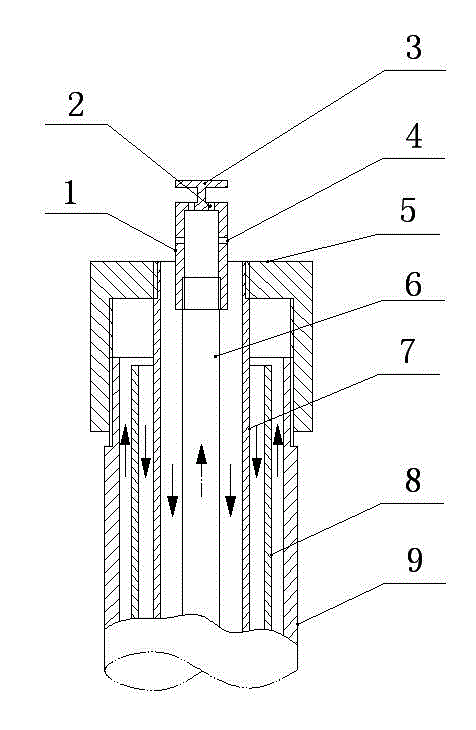

[0030] See the specific structure figure 1 , figure 2, The sampling probe 25 used for water spray and dust removal is composed of an outer pipe 8, an isolation pipe 7, a sampling pipe 6 and a washing water pipe 5, and is arranged at the front end of the system. The washing water pipe 5, the sampling pipe 6, the isolation pipe 7, and the outer pipe 8 are installed in the sampling probe 25 in the order of the washing water pipe 5, the sampling pipe 6, the isolation pipe 7, and the outer pipe 8 from the inside to the outside. The front end of the washing water pipe 5 is equipped with a dust removal nozzle 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com