Method for making energy storage device

A manufacturing method and energy storage device technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of insufficient moisture removal, long baking time, etc., achieve good aging resistance, and increase product capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

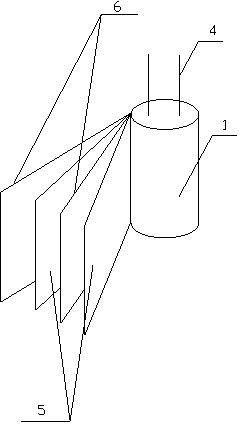

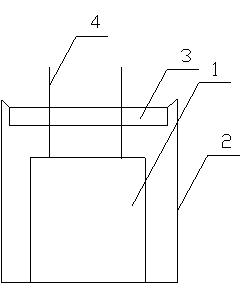

Image

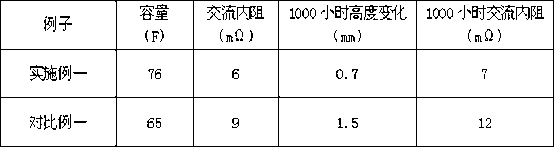

Examples

Embodiment 1

[0042] The manufacturing method of the energy storage device of the present invention:

[0043] Step 1, to 1500m 2 The activated carbon above / g is the active material, and the mixture of conductive carbon black and conductive graphite is used as the conductive agent, and the weight ratio of activated carbon to the conductive agent is 1:9, and it is dry mixed in a V-type mixer, and the mixing time is 30 minutes;

[0044] Step 2, the mixture is sprayed into the PTFE emulsion diluted by a mixture with a weight ratio of ethanol and water of 1:3 in a stirring and mixing granulator, and granulated. The weight percent concentration of the diluted PTFE emulsion is 20%;

[0045] Step 3, passing the granulated material through a sieving machine. Take 2 to 5mm of the particles;

[0046] In step 4, the screened material is fed through a screw feeder, and heated and rolled three times in a four-roller roller press to become a self-supporting film;

[0047] Step 5, coating the aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com