Preparation method of calcium-containing soluble hemostatic material

A hemostatic material and soluble technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of unsuitability for large-scale production, large ethanol, high production cost, etc., and achieve suitable for large-scale production, mild process conditions, and safe production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

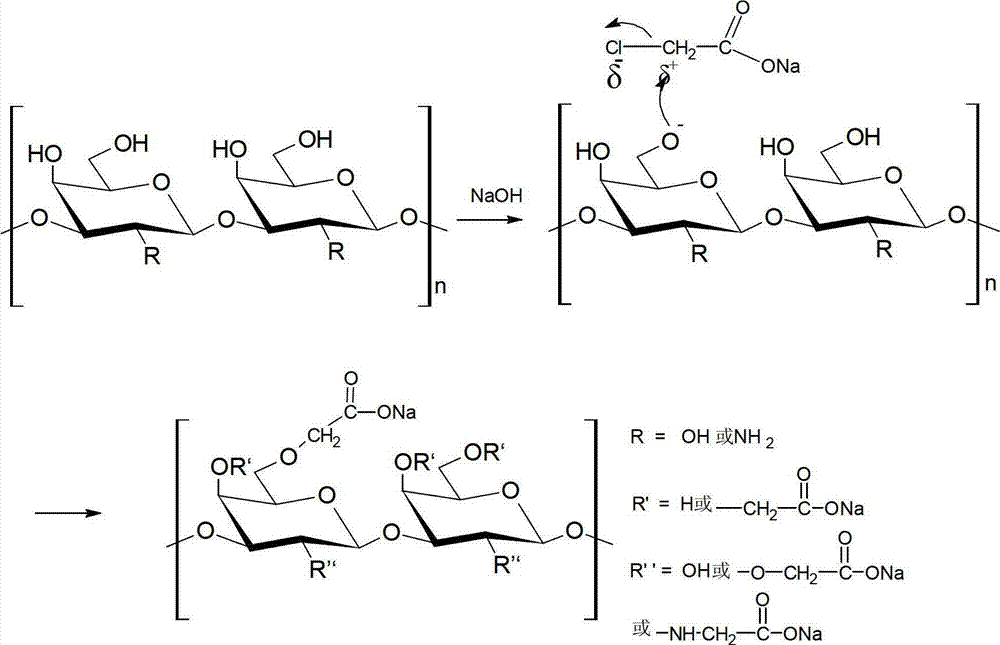

Method used

Image

Examples

Embodiment 1

[0026] (1) Wind the selected polysaccharide fiber layer by layer on the instrument, and immerse it in the ethanol aqueous solution of sodium hydroxide. The content of sodium hydroxide in the ethanol aqueous solution of sodium hydroxide is 60g / L, and the volume ratio of ethanol to water 80%, bath ratio (mass ratio of polysaccharide fiber to ethanol aqueous solution of sodium hydroxide) is 1:20, control the reaction liquid in the instrument to flow continuously, and alkalize for 1h.

[0027] (2) After alkalization is completed, add chloroacetic acid and etherify at 60°C for 1 hour.

[0028] (3) After the etherification is completed, remove the solution on the polysaccharide fiber, put it into the alcoholic aqueous solution of calcium chloride, the mass percentage concentration of calcium chloride in the alcoholic aqueous solution of calcium chloride is 0.5%, and the volume of alcohol and water The ratio is 30%, and the ion exchange reaction takes 20 minutes.

[0029] (4) After ...

Embodiment 2

[0032] (1) After the etherification is completed, remove the solution on the polysaccharide fiber, put it into the alcoholic aqueous solution of calcium chloride, the mass percentage concentration of calcium chloride in the alcoholic aqueous solution of calcium chloride is 1%, and the volume of alcohol and water The ratio is 30%, and the ion exchange reaction takes 20 minutes.

[0033] (2) Wash 2 to 3 times with 30% ethanol by volume, wash off the salt generated by the reaction, and dry with hot air.

[0034] (3) The remaining procedures are the same as in Example 1.

[0035] The calcium content of the prepared calcium-containing soluble hemostatic material reaches more than 0.1% (w / w), and the alcohol washing step can save 40-50% of ethanol compared with the existing patent.

Embodiment 3

[0037] (1) After the etherification is completed, remove the solution on the polysaccharide fiber, put it into the alcoholic aqueous solution of calcium chloride, the mass percentage concentration of calcium chloride in the alcoholic aqueous solution of calcium chloride is 2%, and the volume of alcohol and water The ratio is 30%, and the ion exchange reaction takes 10 minutes.

[0038] (2) Wash 2 to 3 times with 30% ethanol by volume, wash off the salt generated by the reaction, and dry with hot air.

[0039] (3) The remaining procedures are the same as in Example 1.

[0040] The calcium content of the prepared calcium-containing soluble hemostatic material reaches more than 0.1% (w / w), and the alcohol washing step can save 40-50% of ethanol compared with the existing patent.

[0041] The polysaccharide fibers used in the above examples are preferably cotton, hemp, chitosan, etc., and the prepared calcium-containing soluble hemostatic material can be made into medical dressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com