High-sensitivity SERS (surface enhanced Raman scattering) sensor active-substrate for drug detection and preparation method thereof

An active substrate and substrate technology, which is applied in the field of laser Raman spectroscopy and trace drug detection, can solve the problems affecting the detection sensitivity, performance and difficulties of the drug detection system, and achieve significant enhancement effect, low cost and high repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the SERS active silver substrate with surface Raman scattering activity proposed by the present invention comprises the following steps:

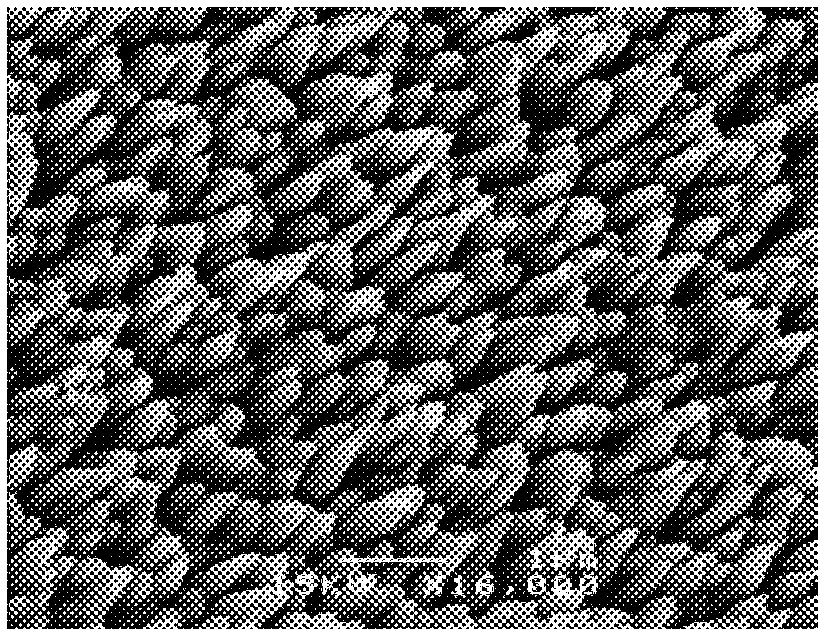

[0027] (1) Magnetron sputtering (ULVAC, MPS-2000-HC3 type) is used to plate a silver film on the substrate, and a 99.99% high-purity silver target is sputtered in high-purity (99.995%) argon gas. The substrate was ultrasonically cleaned in ethanol for 15 minutes before sputtering, and the working vacuum was 2×10 -6 Pa, the thickness of the silver film can be controlled from 100nm to 1000nm by adjusting the sputtering time.

[0028] (2) Evaporate a carbon film layer on the silver film layer as an "inducing template" to induce the formation of pyramidal nanostructures, and its thickness is controlled at about 100nm.

[0029](3) Put the above-mentioned substrate coated with silver film and carbon film into an ion beam system equipped with an ultra-high vacuum and a Kaufmann-type ion gun. Among them, the 600eV...

Embodiment 1

[0032] (1) Magnetron sputtering (ULVAC, MPS-2000-HC3) is used to plate a silver film on the substrate, and a 99.99% high-purity silver target is sputtered in high-purity (99.995%) argon gas. The substrate was ultrasonically cleaned in ethanol for 15 minutes before sputtering, and the working vacuum was 2×10 -6 Pa, the sputtering time is 200s, and the silver film thickness is 200nm.

[0033] (2) Evaporate a carbon film layer on the silver film layer as an "inducing template" to induce the formation of pyramidal nanostructures, and its thickness is controlled at about 100nm.

[0034] (3) Put the above-mentioned substrate coated with silver film and carbon film into an ion beam system equipped with an ultra-high vacuum and a Kaufmann-type ion gun. Among them, the 600eV argon ion beam is focused into a microbeam with a diameter of 380um, and its average ion current density is 220uA / cm 2 . The angle between the ion beam and the sample surface can be adjusted to 45 degrees by cha...

Embodiment 2

[0037] (1) Magnetron sputtering (ULVAC, MPS-2000-HC3) is used to plate a silver film on the substrate, and a 99.99% high-purity silver target is sputtered in high-purity (99.995%) argon gas. The substrate was ultrasonically cleaned in ethanol for 15 minutes before sputtering, and the working vacuum was 2×10 -6 Pa, the sputtering time is 300s, and the silver film thickness is 300nm.

[0038] (2) Evaporate a carbon film layer on the silver film layer as an "inducing template" to induce the formation of pyramidal nanostructures, and its thickness is controlled at about 100nm.

[0039] (3) Put the above-mentioned substrate coated with silver film and carbon film into an ion beam system equipped with an ultra-high vacuum and a Kaufmann-type ion gun. Among them, the 600eV argon ion beam is focused into a microbeam with a diameter of 380um, and its average ion current density is 220uA / cm 2 . The angle between the ion beam and the sample surface can be adjusted to 45 degrees by cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com