Fast production method of high-purity metal sulphamate

A technology of sulfamate and production method, applied in the directions of sulfamic acid, nitrogen and non-metallic compounds, etc., can solve problems such as slow reaction of sulfamate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

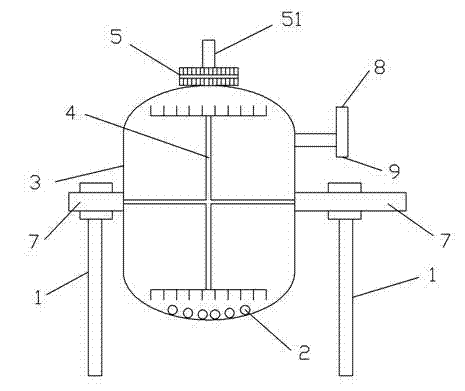

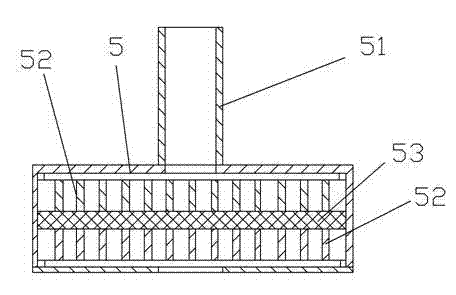

Method used

Image

Examples

Embodiment 1

[0021] Nickel powder, sulfamic acid powder and pure water in a ratio of 0.5︰1:4-6 by weight, heat the pure water to 40-60°C, add nickel powder, sulfamic acid powder and pure water into a ball (zirconia balls or agate balls), add high-pressure oxygen to a reaction pressure of 0.5 to 1 standard atmosphere, grind and stir the reaction for 90 minutes, and filter the reaction solution to obtain a nickel sulfamate solution. Nickel sulfamate crystals can be obtained after heating and evaporation. The average diameter of the nickel powder is less than 100nm.

Embodiment 2

[0023] Nickel powder, sulfamic acid powder and pure water in a ratio of 1.0:1:4-6 by weight, add nickel powder and sulfamic acid powder into a closed reaction tank equipped with grinding balls (zirconia balls or agate balls), and stir Ball mill for 90 minutes, add pure water at 40-60°C, add high-pressure oxygen until the reaction pressure is 0.5 to 1 standard atmosphere, grind and stir for 90 minutes, then filter the reaction solution to obtain nickel sulfamate solution. Nickel sulfamate crystals can be obtained after heating and evaporation; the average diameter of the nickel powder is 50-100nm.

Embodiment 3

[0025] Nickel powder, sulfamic acid powder and pure water are in the ratio of 1.5︰1:4-6 by weight, heat the pure water to 40-60°C, add nickel powder, sulfamic acid powder and pure water to the grinding ball (zirconia Balls or agate balls) in the reaction tank, the total volume of the balls is half of the volume of pure water, high pressure oxygen is added to the reaction pressure of 0.5 to 1 standard atmosphere, and after the ball mill is stirred for 90 minutes, the reaction solution is filtered to obtain nickel sulfamate solution. Nickel sulfamate crystals can be obtained after heating and evaporation. The average diameter of the nickel powder is 50-100nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com