ZrC (Zirconium Carbide) ceramic precursor, ZrC ceramic and preparation method thereof

A ceramic precursor and ceramic technology, applied in the field of ceramics, can solve the problems of low yield of ZrC ceramics, inability to store for a long time, poor operability, etc., and achieve the effects of fine grains, complete mutual dissolution and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Another aspect of the present invention also provides a kind of preparation method of aforementioned ZrC ceramics, comprises the following steps,

[0038] 1. Carrying out the cross-linking reaction of the aforementioned ZrC ceramic precursor solution at a cross-linking reaction temperature of 100-250° C. for 0.5-4 hours to obtain a cross-linked ZrC ceramic precursor;

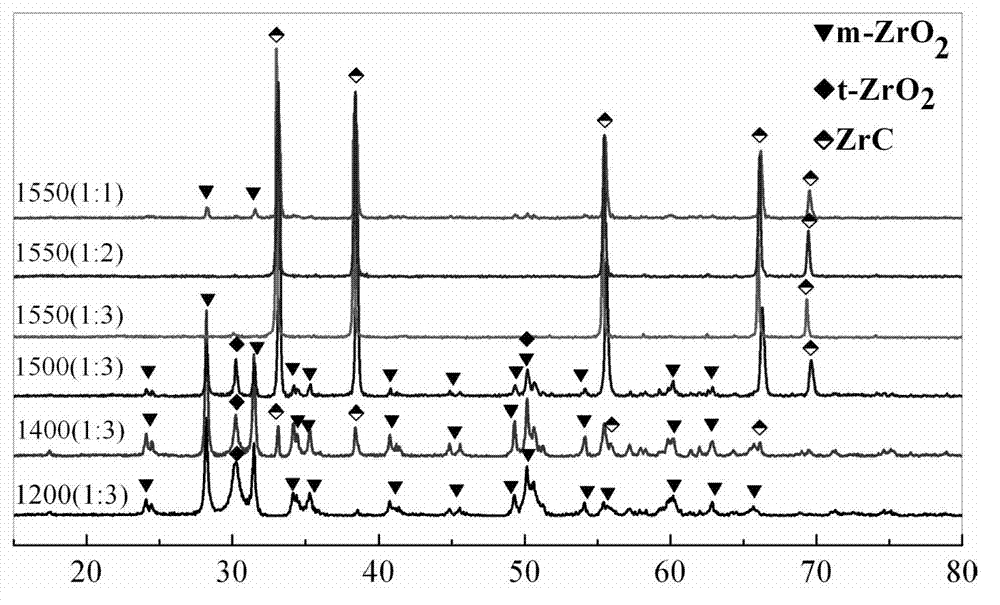

[0039] 2. The cross-linked ZrC ceramic precursor is subjected to a cracking reaction at a cracking reaction temperature of 1400-1600° C. for 0.5-2 hours under an inert atmosphere or a vacuum condition to obtain a ZrC ceramic.

[0040] In the preparation method of ZrC ceramics provided by the present invention, since the zirconium source and the bidentate ligand form a coordination intermediate, the miscibility with the carbon source is more thorough and the combination is tighter, which reduces the energy loss during the combination process between the carbon source and the zirconium source , the cracking...

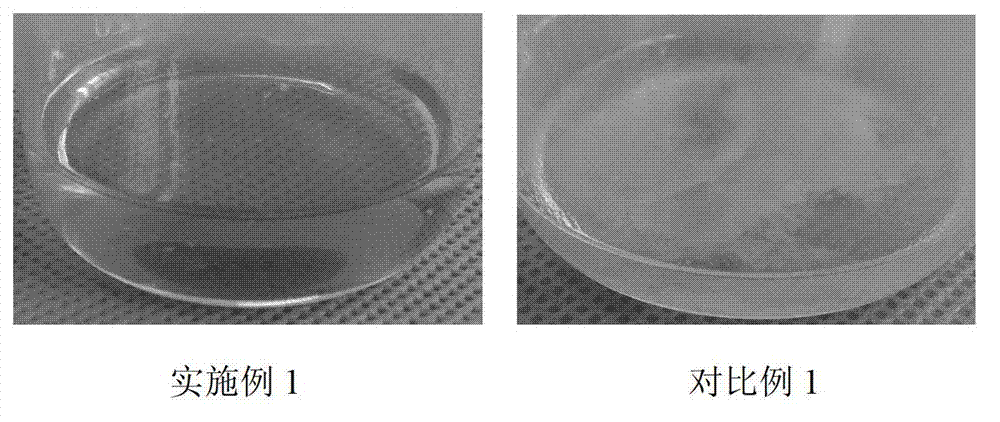

Embodiment 1

[0046] a) ZrOCl with a molar ratio of 1:1:2:9 2 ·8H 2 O, phenolic resin, acetylacetone and dehydrated alcohol are placed in container, stir, obtain ZrC ceramic precursor;

[0047] b) keeping the ZrC ceramic precursor at 100° C. for 2 hours to obtain a crosslinked precursor gel;

[0048] c) Put the precursor gel into a mold, put it into a high-temperature cracking furnace, raise the temperature to 1400° C., keep it warm for 2 hours, and take it out to obtain ZrC ceramics.

Embodiment 2

[0050] a) ZrOCl with a molar ratio of 1:3:1:2 2 ·8H 2 O, phenolic resin, ethylene glycol and dehydrated alcohol are placed in container, stir, obtain ZrC ceramic precursor;

[0051] b) keeping the ZrC ceramic precursor at 250° C. for 0.5 hours to obtain a crosslinked precursor gel;

[0052] c) Put the precursor gel into a mold, put it into a high-temperature cracking furnace, raise the temperature to 1600° C., keep it warm for 0.5 hours, and take it out to obtain ZrC ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com