Essence with fragrance of thick broad-bean sauce and preparation method of essence

A technology for the aroma and essence of bean paste, which is applied in food preparation, application, food science and other directions, can solve the problems of short aroma retention period and instability, and achieve the effect of strong aroma, long-lasting and comfortable aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The present invention will be further described with the production process of producing 100kg with the essence of bean paste sauce fragrance below:

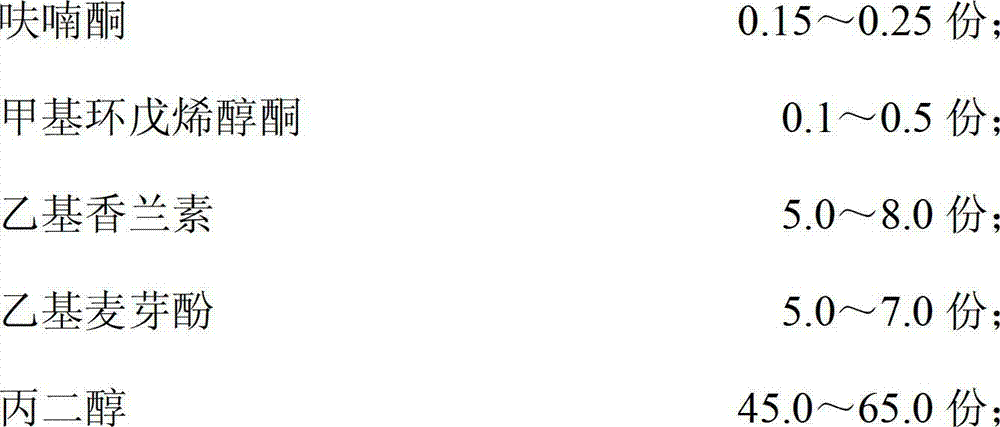

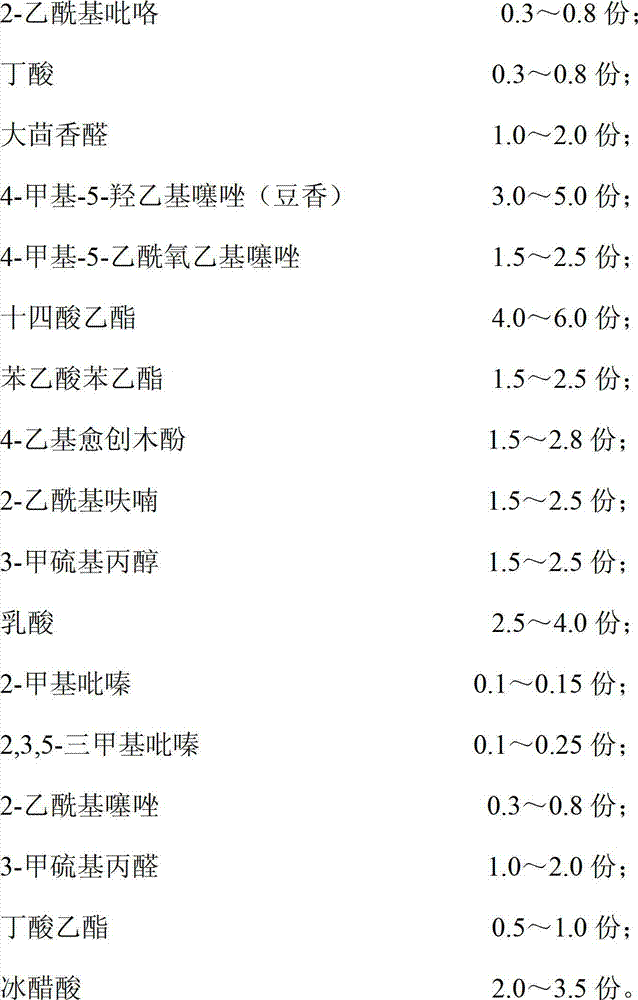

[0014] Producing 100kg of flavor with bean paste flavor ratio:

[0015]

[0016]

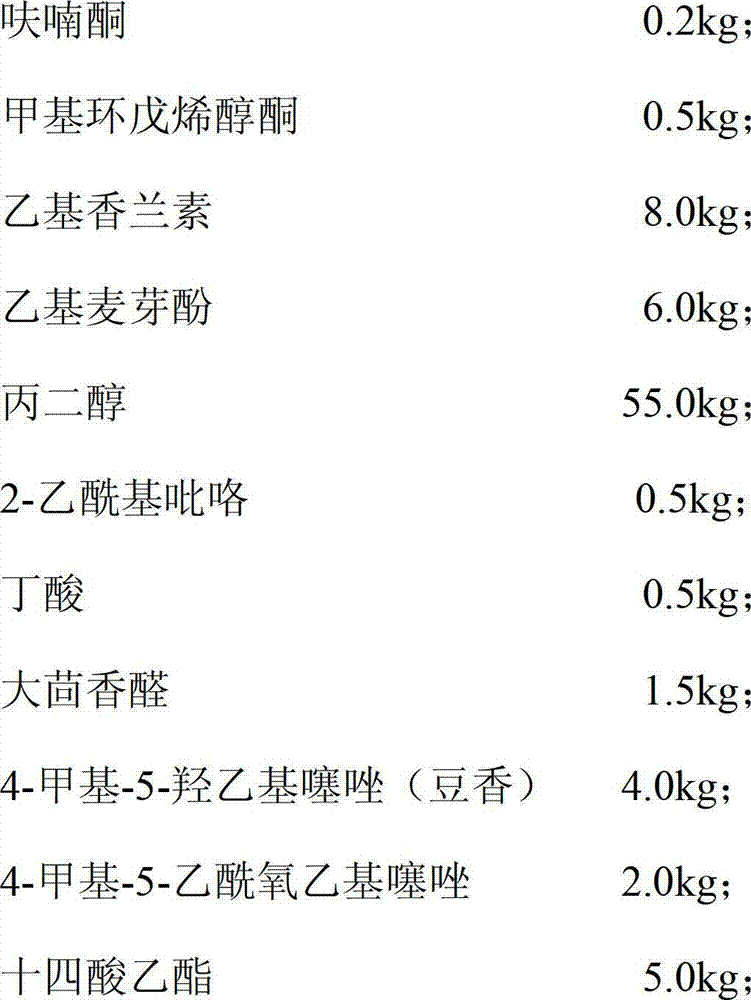

[0017] The production process is as follows: first add 0.2kg of furanone, 0.5kg of methylcyclopentenolone, 8.0kg of ethyl vanillin, 6.0kg of ethyl maltol and 55.0kg of propylene glycol into the stainless steel electric mixing tank, cover Start the mixer with a good cylinder head, stir the solid fragrance raw materials until they are completely dissolved, let stand for 5 minutes, then add 0.5kg of 2-acetylpyrrole, 0.5kg of butyric acid, 1.5kg of anisaldehyde, 4-methyl-5 -Hydroxyethylthiazole (bean fragrance) 4.0kg, 4-methyl-5-acetoxyethylthiazole 2.0kg, ethyl myristate 5.0kg, phenylethyl phenylacetate 2.0kg, 4-ethyl guaiac wood 2.0kg of phenol, 2.0kg of 2-acetylfuran, 2.0kg of 3-methylthiopropanol, 3.0kg of lactic acid, 0.1kg of 2-met...

Embodiment 2

[0020] The present invention will be further described with the production process of producing this bean paste essence of 100kg below:

[0021] The ratio of producing 100kg of this bean paste essence is:

[0022]

[0023]

[0024] The production process is as follows: first add 0.15kg of furanone, 0.45kg of methylcyclopentenolone, 6.0kg of ethyl vanillin, 5.5kg of ethyl maltol and 55.0kg of propylene glycol into the stainless steel electric mixing tank, cover Start the mixer with a good cylinder head, stir the solid fragrance raw materials until they are completely dissolved, let stand for 5 minutes, then add 0.5kg of 2-acetylpyrrole, 0.5kg of butyric acid, 1.5kg of anisaldehyde, 4-methyl-5 -Hydroxyethylthiazole (bean fragrance) 4.5kg, 4-methyl-5-acetoxyethylthiazole 2.2kg, ethyl myristate 5.2kg, phenylethyl phenylacetate 2.2kg, 4-ethyl guaiac 2.5kg of phenol, 2.0kg of 2-acetylfuran, 2.0kg of 3-methylthiopropanol, 3.0kg of lactic acid, 0.1kg of 2-methylpyrazine, 0.2kg ...

Embodiment 3

[0027] The present invention will be further described with the production process of producing this bean paste essence of 100kg below:

[0028] The ratio of producing 100kg of this bean paste essence is:

[0029]

[0030]

[0031] The production process is: first add 0.2kg of furanone, 0.3kg of methylcyclopentenolone, 6.5kg of ethyl vanillin, 5.3kg of ethyl maltol and 55.4kg of propylene glycol into the stainless steel electric mixing tank, cover Start the mixer with a good cylinder head. After the solid fragrance raw materials are stirred vigorously until they are completely dissolved, let stand for 5 minutes, and then add 0.5kg of 2-acetylpyrrole, 0.8kg of butyric acid, 2.0kg of anisaldehyde, 4-methyl-5 -Hydroxyethylthiazole (bean fragrance) 3.0kg, 4-methyl-5-acetoxyethylthiazole 2.0kg, ethyl myristate 5.5kg, phenylethyl phenylacetate 2.5kg, 4-ethyl guaiac wood Phenol 2.8kg, 2-acetylfuran 2.0kg, 3-methylthiopropanol 1.5kg, lactic acid 4.0kg, 2-methylpyrazine 0.1kg, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com