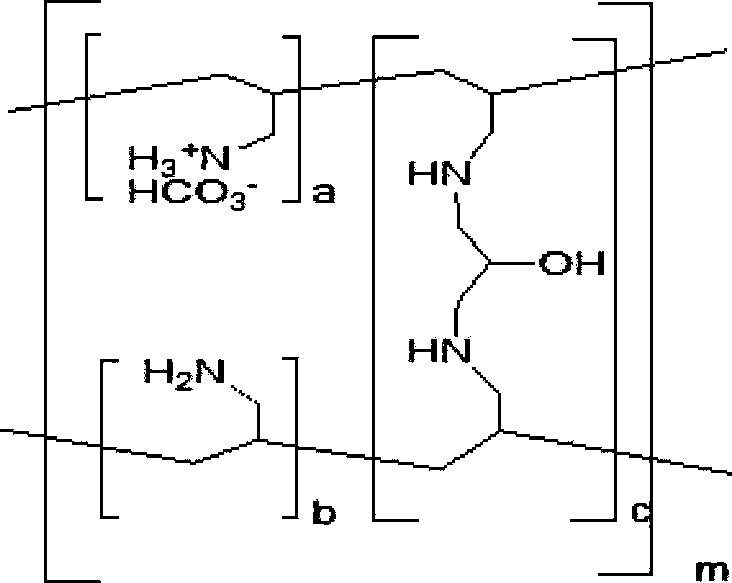

Sevelamer carbonate crude drug for preparing tablets, preparation method and application thereof

A technology of sevelamer carbonate and wet products of sevelamer carbonate, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, pill delivery, etc., can solve the problem of compressibility of sevelamer carbonate tablets that have not been proposed Correlation and other issues, to avoid the risk of systemic absorption, good hardness, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Crude Sevelamer Carbonate

[0043] 1. Sevelamer hydrochloride 1kg, NaHC0 3 1kg and 20kg of water were added to the reaction vessel, stirred and reacted at about 60°C for 4h, and filtered.

[0044] 2. The solid obtained in step 1, 1kg NaHCO 3 Add 15kg of water into the reaction vessel, adjust the pH of the feed solution to 9.5 with NaOH, continue to stir and react for 4 hours at 60°C, and filter;

[0045] 3. Put the Sevelamer Carbonate obtained in step 2 into a washing tank, add an appropriate amount of purified water, stir, let it stand, and extract the supernatant, and repeat this until the conductivity is not greater than 30 μs / cm, and filter to obtain a wet product of Sevelamer Carbonate .

[0046] 4. The wet product of sevelamer carbonate was dried at 80°C for 16 hours to obtain 788 g of crude product of sevelamer carbonate, with a yield of 78.8%.

Embodiment 2

[0048] Preparation of Crude Sevelamer Carbonate

[0049] 1. Sevelamer hydrochloride 20kg, NaHCO 3 20kg and 160kg of water were added to the reaction vessel, stirred and reacted at 60°C for 4h, and the solid was collected by centrifugation.

[0050] 2, the solid obtained in step 1 and 20kg NaHCO 3 Add 240kg of water into the reaction vessel, adjust the pH of the feed solution to 10.8 with NaOH, continue stirring and reacting at 55-65°C for 4 hours, and collect the solid by centrifugation;

[0051] 3. Put the sevelamer carbonate obtained in step 2 into a washing tank, add an appropriate amount of purified water, stir, and centrifugally filter, repeat this until the conductivity of the eluate is not greater than 30 μs / cm, and then centrifuge to obtain a wet product of sevelamer carbonate .

[0052] 4. The wet product of sevelamer carbonate was dried in a hot air circulation oven at 80°C for 16 hours to obtain 17.4 kg of crude product of sevelamer carbonate, with a yield of 87....

Embodiment 3

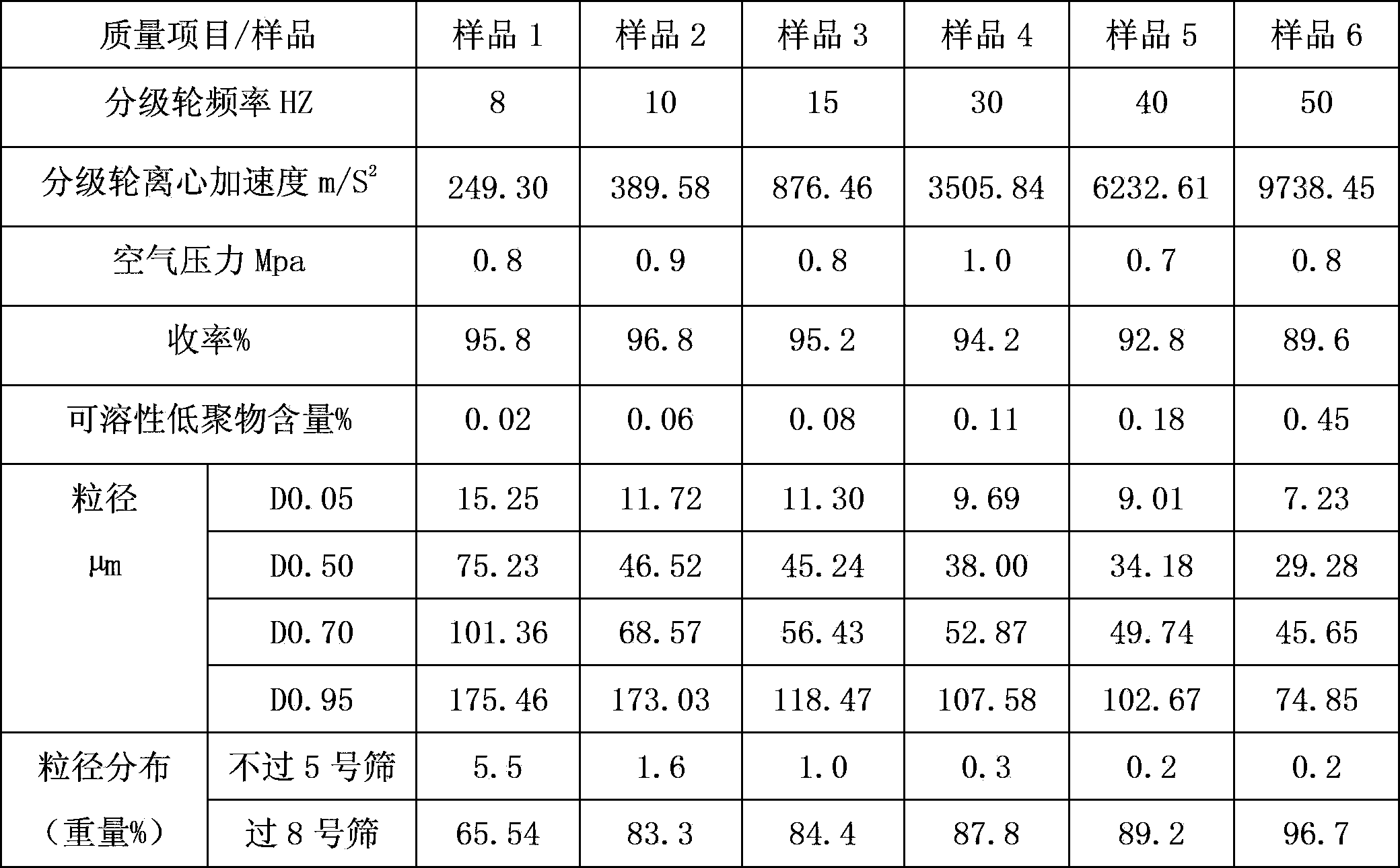

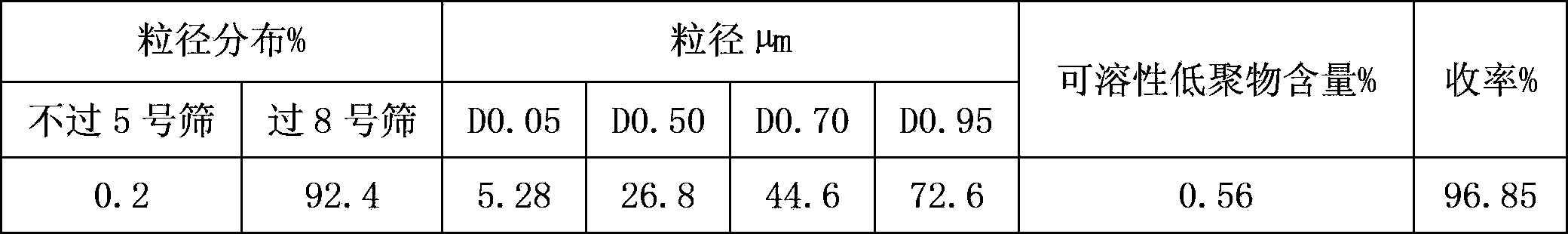

[0054] Take the crude product of sevelamer carbonate (prepared in Example 2), pulverize it with a type 20 fluidized bed jet mill, the air pressure of the pulverizer is 0.7-1.0Mpa, the diameter of the classifying wheel is 0.2m, and the frequency of the classifying wheel is 10-40Hz; The carbonic acid sevelamer is tested for quality, and the results are listed in Table 1:

[0055] Table 1

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com