White roof panel laser soldering process control device

A brazing process and control device technology, which is applied in the field of laser brazing process control device for body-in-white roof, can solve problems such as many equipment units and complex process control, and achieve the effects of ensuring quality and reducing failure downtime rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

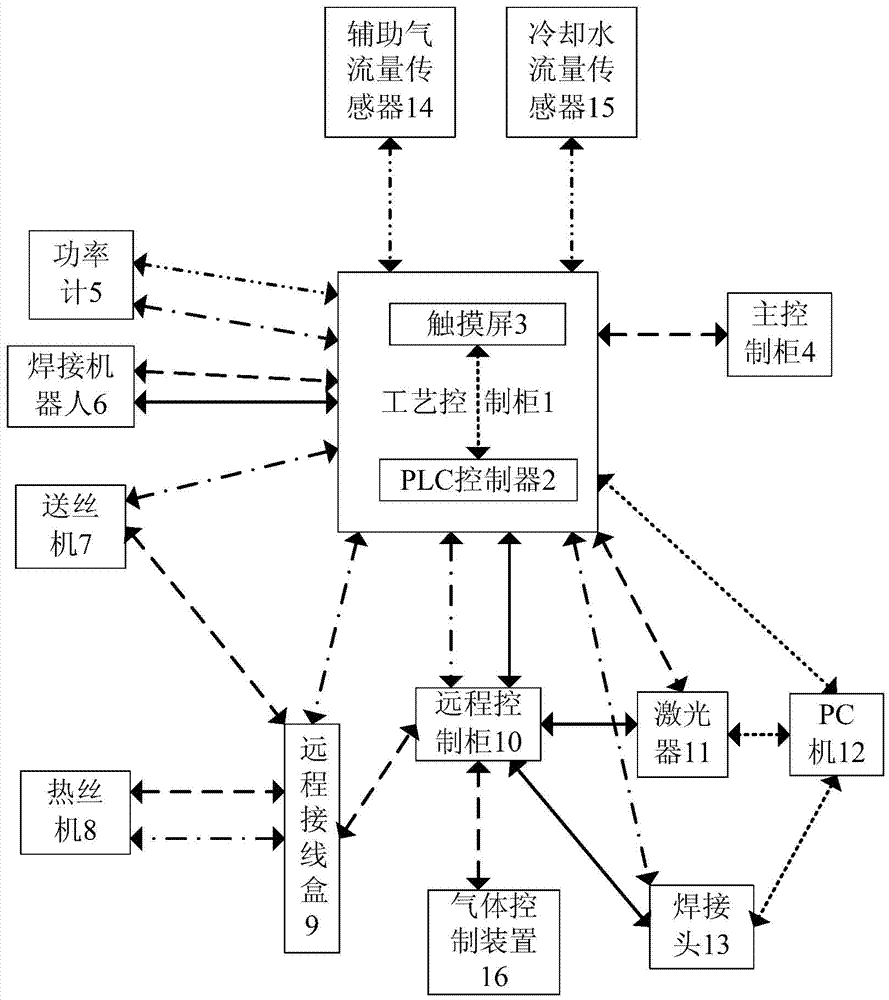

[0019] As shown in Figure 1, it is the equipment connection diagram of the laser brazing process control device for the roof cover of the vehicle body of the present invention, the process control device includes a process control cabinet 1, and the process control cabinet 1 makes the welding robot 6 and the wire feeder 7 according to the welding process requirements , hot wire machine 8, laser 11, welding head 13, power meter 5 and other related peripheral equipment complete their respective actions in an orderly manner.

[0020] The process control cabinet 1 further includes a PLC controller 2 and a touch screen 3 . The touch screen 3 is mainly for setting process parameters, and the PLC controller 2 is for logic control of external equipment, and the two exchange data through Ethernet. The program upload / download of the PLC controller 2 in the process control cabinet 1 and the parameter setting of the welding head 13 and the laser 11 are all connected to the PC 12 through E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com