Rolled copper foil and negative electrode of lithium ion secondary battery using same

A secondary battery, rolled copper foil technology, applied in secondary batteries, battery electrodes, electrode carriers/current collectors, etc., can solve the problem of inability to obtain high adhesion, complex structure, rough The problems such as the weakening of the fixation effect of the chemical particles, and the effect of improving the long life, improving the volume energy density, and improving the safety are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~26、 comparative example 1~12

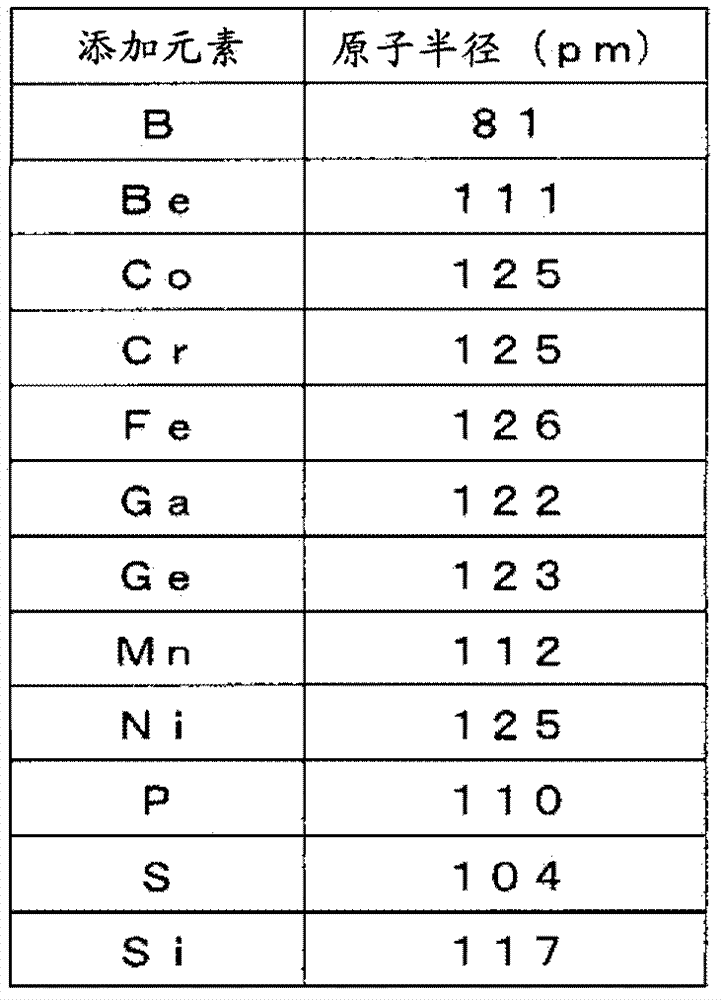

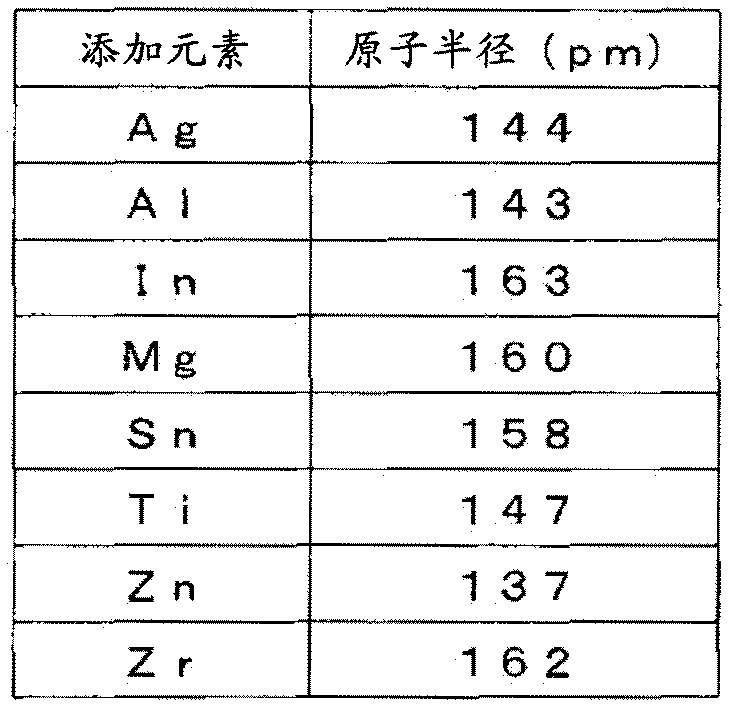

[0086] Using oxygen-free copper as the base material, smelting Figure 6 and Figure 7 The alloys shown are composed of copper alloys, cast in ingots. The ingot is hot-rolled to form a sheet, and after the sheet is cold-rolled and billet annealed in the order, the final cold-rolling is performed at a working degree of 85 to 95% to make the thickness 10 μm, thereby obtaining Examples 1 to 26 and Rolled copper foil of Comparative Examples 1-12.

[0087]

[0088] The content of each evaluation is as follows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com