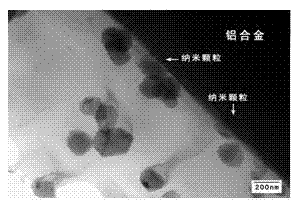

Nanometer alumina particle enhanced conversion film preparation method

A nano-alumina and particle-reinforced technology, applied in the coating process of metal materials, etc., can solve problems such as obstruction, pollution of treatment liquid, difficulty in forming a solution with uniform dispersion of nanoparticles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1# process steps and parameters:

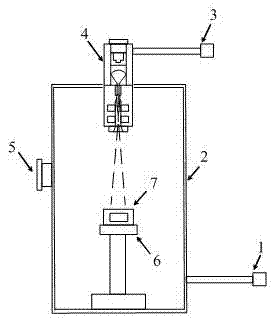

[0037] The first step, the method of electron beam charging the surface of alumina particles

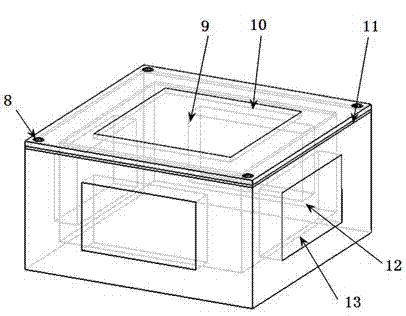

[0038] 1) Put the nano-alumina particles into the sample box as mentioned above;

[0039] 2) Open the vacuum chamber of the electron beam equipment, and put the sample box containing nano-alumina particles on the sample stage;

[0040] 3) Close the vacuum chamber, turn on the mechanical pump to vacuum the electron beam vacuum chamber and electron gun to 10Pa, turn on the molecular pump to pump the electron beam vacuum chamber and electron gun to 0.005Pa;

[0041] 4) Set the high voltage of the electron gun to 30kW, the beam current density to 300mA, and the electron beam spot to be circular;

[0042] 5) Start the electron beam setting to charge the nanoparticles, the charging time is 30 minutes, and turn off the electron beam equipment after the time is up;

[0043] 6) Turn off the molecular pump and the mechanical pump in sequence, and sl...

Embodiment 2

[0062] 1# process steps and parameters:

[0063] The first step, the method of electron beam charging the surface of alumina particles

[0064] 1) Put the nano-alumina particles into the sample box as mentioned above;

[0065] 2) Open the vacuum chamber of the electron beam equipment, and put the sample box containing nano-alumina particles on the sample stage;

[0066] 3) Close the vacuum chamber, turn on the mechanical pump to vacuum the electron beam vacuum chamber and electron gun to 0.1Pa, turn on the molecular pump to pump the electron beam vacuum chamber and electron gun to 0.0005Pa;

[0067] 4) Set the high voltage of the electron gun to 10kW, the beam current density to 100mA, and the electron beam spot to be circular;

[0068] 5) Start the electron beam setting to charge the nanoparticles, the charging time is 5 minutes, and turn off the electron beam equipment after the time is up;

[0069] 6) Turn off the molecular pump and the mechanical pump in sequence, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com