A kind of electrolytic polishing liquid and electrolytic polishing process for titanium and titanium alloy

An electrolytic polishing and titanium alloy technology, applied in the field of metal surface treatment, can solve the problems of difficult preparation, complex composition, poor stability of polishing process, etc., and achieve the effect of simple production, simple equipment, easy preparation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

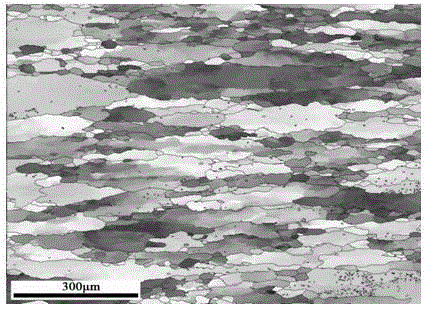

[0026] Embodiment 1, a kind of electrolytic polishing process that is used for titanium and titanium alloy EBSD sample, comprises the steps:

[0027] (1) Grinding of the sample: use 400 mesh, 600 mesh, 800 mesh, 1500 mesh and 2000 mesh metallographic sandpaper to polish the Ti-3Al-4Cr-2Fe titanium alloy in sequence, clean the surface and dry it;

[0028] (2) Prepare electrolytic polishing liquid: prepare according to formula 1 in the above table;

[0029] (3) Take the polished Ti-3Al-4Cr-2Fe titanium alloy sample as an anode, connect it to the positive pole of a DC power supply and immerse it in the electrolytic cell filled with the electrolytic polishing solution prepared in step (2);

[0030] (4) With the stainless steel sheet as the cathode, connect to the negative pole of the DC stabilized power supply and immerse in the electrolytic cell filled with the above-mentioned electrolytic polishing solution;

[0031] (5) Polishing is carried out in above-mentioned electrolytic ...

Embodiment 2

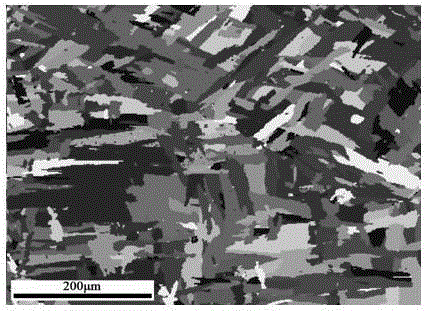

[0034] Embodiment 2: a kind of electrolytic polishing process that is used for titanium and titanium alloy EBSD sample, comprises the steps:

[0035] (1) sample grinding: with embodiment 1;

[0036] (2) Prepare electrolytic polishing liquid: prepare according to formula 2 in the above table;

[0037] (3) With the polished TC4 titanium alloy sample as the anode, it is connected to the positive pole of the DC power supply and immersed in an electrolytic cell filled with electrolytic polishing solution;

[0038] (4) With the stainless steel sheet as the cathode, it is connected to the negative pole of the DC stabilized power supply and immersed in an electrolytic cell filled with electrolytic polishing solution;

[0039] (5) Polishing is carried out in the above-mentioned electrolyte solution, and the polishing temperature is below zero 5-10°C, the polishing time is 35s, the polishing voltage is 60V, and the distance between the anode and the cathode is 60mm.

[0040] (6) Take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com