Anticorrosive preformed pile and manufacturing and constructing method thereof

A prefabricated pile and anti-corrosion technology, used in the field of building foundations, can solve the problems of prolonging the corrosion time, unable to prevent the corrosion of concrete structures and steel bars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

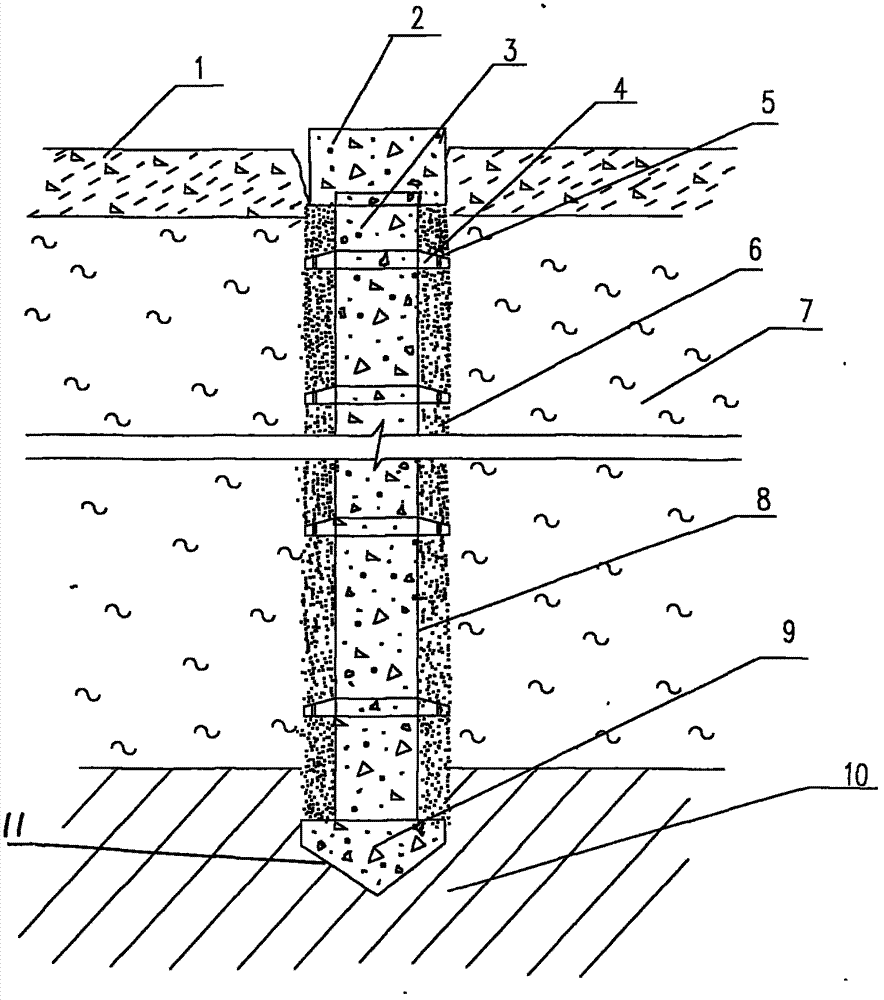

[0016] figure 1 Shown is a typical embodiment of the present invention, and a kind of anti-corrosion prefabricated pile comprises the long columnar reinforced concrete pile body (3) that the cross-loading surface is square, and every 2m on the pile body (3) has ratio pile body ( 3) A pile section (4) with a size of 10cm, the pile section (4) is 10cm wide, the pile section (4) is provided with a longitudinal drainage hole (5), and the pile body (3) and the pile section (4) are coated with asphalt ( 8), there is 10cm thick sand filling (6) outside the asphalt (8), and the surface of the pile point (9) is coated with polyurea (11).

[0017] The following brief description embodiment makes construction steps:

[0018] ①. Binding the reinforcement cage in the prefabricated pile;

[0019] ②. Install the formwork with the pile section (4) and pour the pile body (3) concrete and maintain it;

[0020] ③. After the concrete strength is reached, hoist the pile body (3) into the hot-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com