Maintaining system and maintaining method for circulating fluidized bed

A circulating fluidized bed and curing system technology, which is applied to the circulating fluidized bed curing system and the maintenance field, can solve the problem that the requirements of the furnace lining oven of a large-scale circulating fluidized bed boiler cannot be met, the temperature rise and fall speed is difficult to control, and the quality of the oven is unsatisfactory. There are no guarantees and other problems to achieve the effect of reducing maintenance costs, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

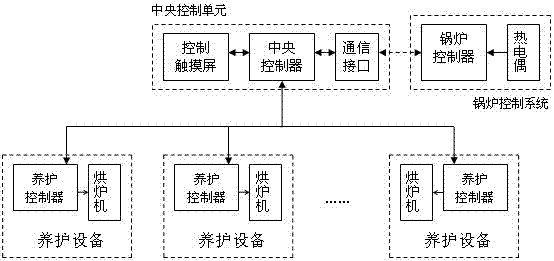

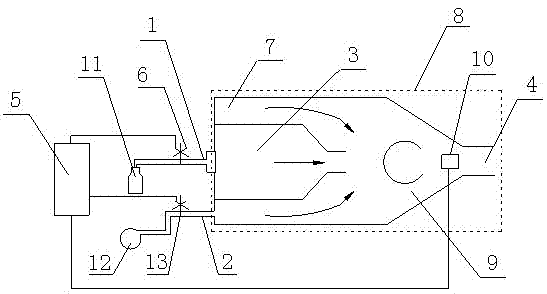

[0029] Such as figure 1 As shown, the circulating fluidized bed maintenance system includes the central control unit and the equipment installed in the boiler ignition chamber, furnace, separator, feeder, slag cooler, bottom cooler, reheater and cyclone. There are multiple sets of maintenance equipment for each maintenance point of the furnace lining. There are about 70 maintenance equipment in total, and each maintenance equipment is connected to the central control unit. The central control unit includes a central controller for comprehensive data processing and control, a control touch screen for display and input, and a communication interface for communicating with the boiler controller. The control touch screen and communication inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com