Polyethylene insulated flexible radio-frequency cable

A technology of polyethylene insulation and polyethylene insulation layer, which is applied in the direction of circuits, electrical components, waveguides, etc., can solve the problems of being easily affected by the environment and climate conditions, the reduction of foamed insulating solid materials, and low transmission quality and efficiency. Realize the effect of high-quality transmission, long service life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

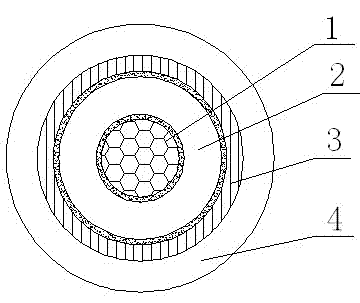

[0009] Polyethylene insulated flexible radio frequency cable is composed of inner conductor, insulating layer, outer conductor and sheath arranged in sequence from inside to outside. The inner conductor is 27 strands of silver-plated copper with a diameter of 0.127mm, and the insulating layer adopts physical foaming technology. Foamed skin-foam-skin insulation layer, the outer diameter of the insulation layer is 2.4 mm, the outer conductor is a silver-plated flat wire and a silver-plated single-wire braided shielding layer, and the inner conductor of the silver-plated copper strand is extruded with polyethylene insulation Layer, braided silver-plated flat wire and silver-plated single-wire braided shielding layer outer conductor on polyethylene insulation layer, extruded polyethylene sheath on the outer conductor, sheath diameter 4.1㎜.

[0010] In order to effectively improve the performance of the cable, more attention should be paid to the improvement of the performance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com