Device for treating aquatic plants in real time and application of device

A technology of aquatic plants, stirring devices, applied in the direction of grain processing, solid waste removal, presses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

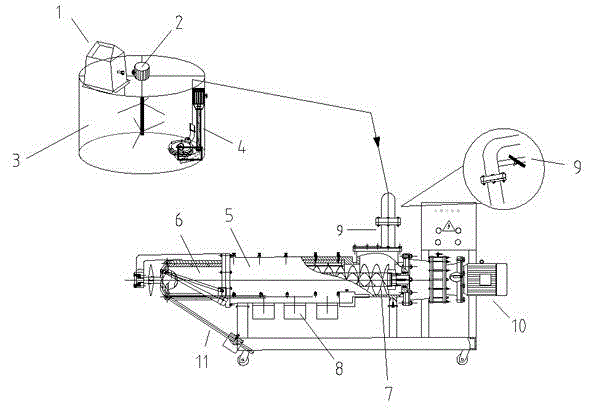

[0032] Depend on figure 1 It can be seen that the present invention includes an early crushing mechanism and a spiral solid-liquid separator, wherein:

[0033] The pulverizing mechanism in the early stage includes a pulverizer 1, a stirring device 2, a stirring tank 3 and a submersible sewage pump 4. The pulverizer 1 is located on the top of the mixing tank 3, and the stirring blade in the agitating device 2 is located on the central axis of the mixing tank 3. The submersible sewage pump The suction port of 4 is located at the bottom of the stirring tank 3, and the output port is docked with the feed port 9 in the spiral solid-liquid separator;

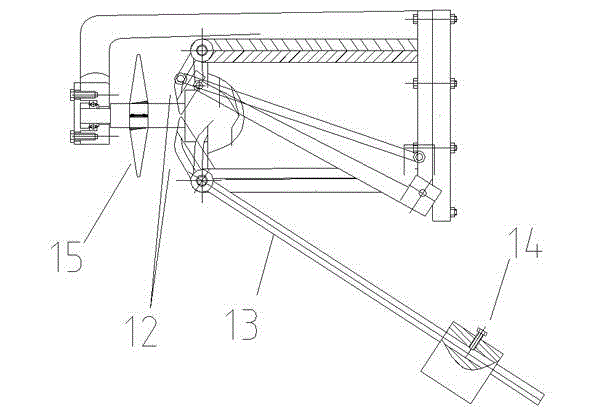

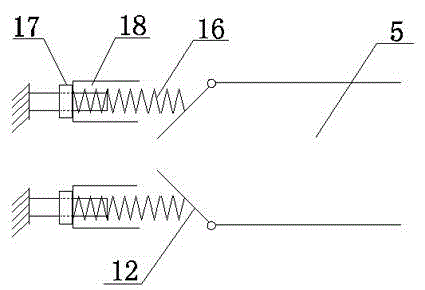

[0034] The screw type solid-liquid separator comprises an extruding channel 5 containing a feed inlet 9, a dehydration outlet 8 and a residue outlet 6. The extruding channel 5 is provided with a matching screw propulsion blade 7, and the diameter of the extruding channel 5 is determined by the feed inlet. The 9 end gradually decreas...

Embodiment 2

[0041] The equipment described in Example 1 is used for instant dehydration treatment of aquatic plants and their residues salvaged from water.

[0042] The aquatic plants or aquatic plant residues salvaged from the water are sent to the entrance of the pulverizer 1 in the previous crushing mechanism through manual feeding or conveyor belt feeding. The feed port 9 of the liquid separator is driven by the driving motor 10, and the screw blade 7 pushes the material to move from the feed port 9 of the extrusion channel 5 to the residue outlet 6. Since the diameter of the extrusion channel 5 gradually decreases, In particular, the residue outlet 6 is also provided with a cover plate 12. The material is extruded in motion, and the extrusion force can be adjusted by the resistance adjustment device 11. The water extruded during the extrusion process is discharged from the dehydration outlet 8. After dehydration The residue is discharged from the residue outlet 6.

[0043] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com