Material surface coating and high-temperature treatment integrated device

A technology of high-temperature treatment and surface coating, which is applied in the direction of drying gas arrangement, drying machine for static materials, lighting and heating equipment, etc., can solve the problems of complicated process, low efficiency and low yield rate, and achieve the purpose of improving production efficiency and saving The effect of simple materials and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

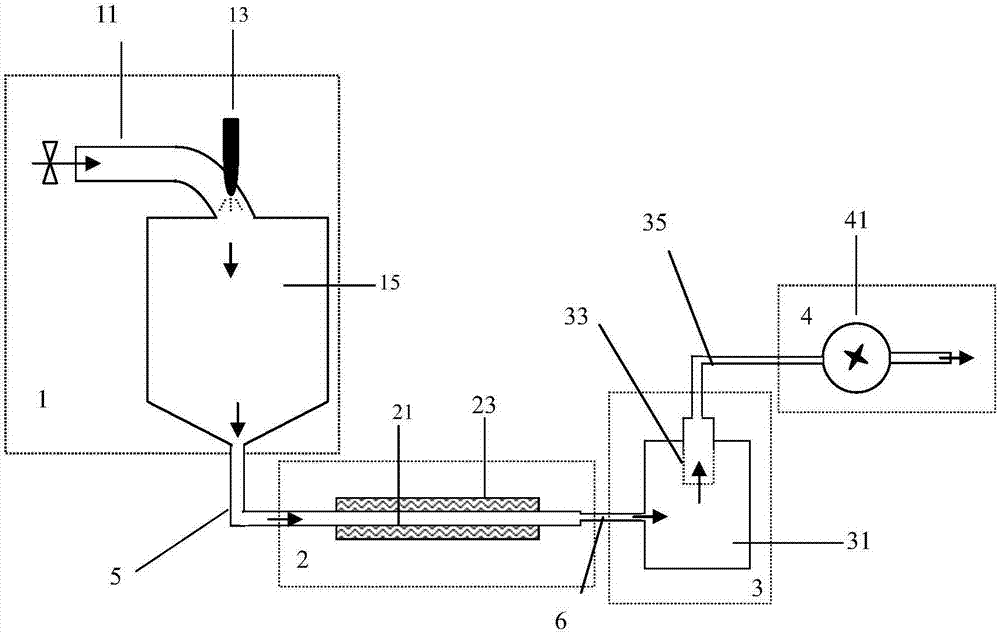

[0026] Please check figure 1 , a combined material surface coating and high-temperature treatment device, comprising a pipeline and a spray drying component 1, a high-temperature treatment component 2, a collection component 3 and an air extraction component 4 connected in sequence;

[0027] The pipeline includes a first connecting pipe 5 connecting the spray drying assembly 1 and the high temperature processing assembly 2, and a second connecting pipe 6 connecting the high temperature processing assembly 2 and the collecting assembly 3;

[0028] The spray drying assembly 1 includes a carrier gas channel 11 for introducing an inert gas, a nozzle 13 for sample injection, and a drying chamber 15; the main body of the drying chamber 15 is cylindrical, with upper and lower openings. The opening is communicated with the carrier gas channel 11, and the lower opening is communicated with the first connecting pipe 5, and the lower opening has a structure whose diameter gradually decre...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that: the air outlet of the exhaust pipe is connected to the air inlet of the carrier gas passage 11, and the carrier gas flows through the spray drying system under the drive of the induced draft fan 41, and the high temperature The treatment system and collection system flow back to the spray drying system, and the entire combined device forms a closed air circulation to realize the recycling of carrier gas, reduce energy consumption and improve efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com