Preparation method of high-reinforcement nanometer CaCO3 for silicone sealant

A silicone sealant and reinforcement technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for material and surface science, can solve the problem of the appearance of silicone sealant products is not bright, the effect of broken and depolymerization is not good, Problems such as poor appearance performance, to achieve the effect of good appearance, good reinforcement, and high reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

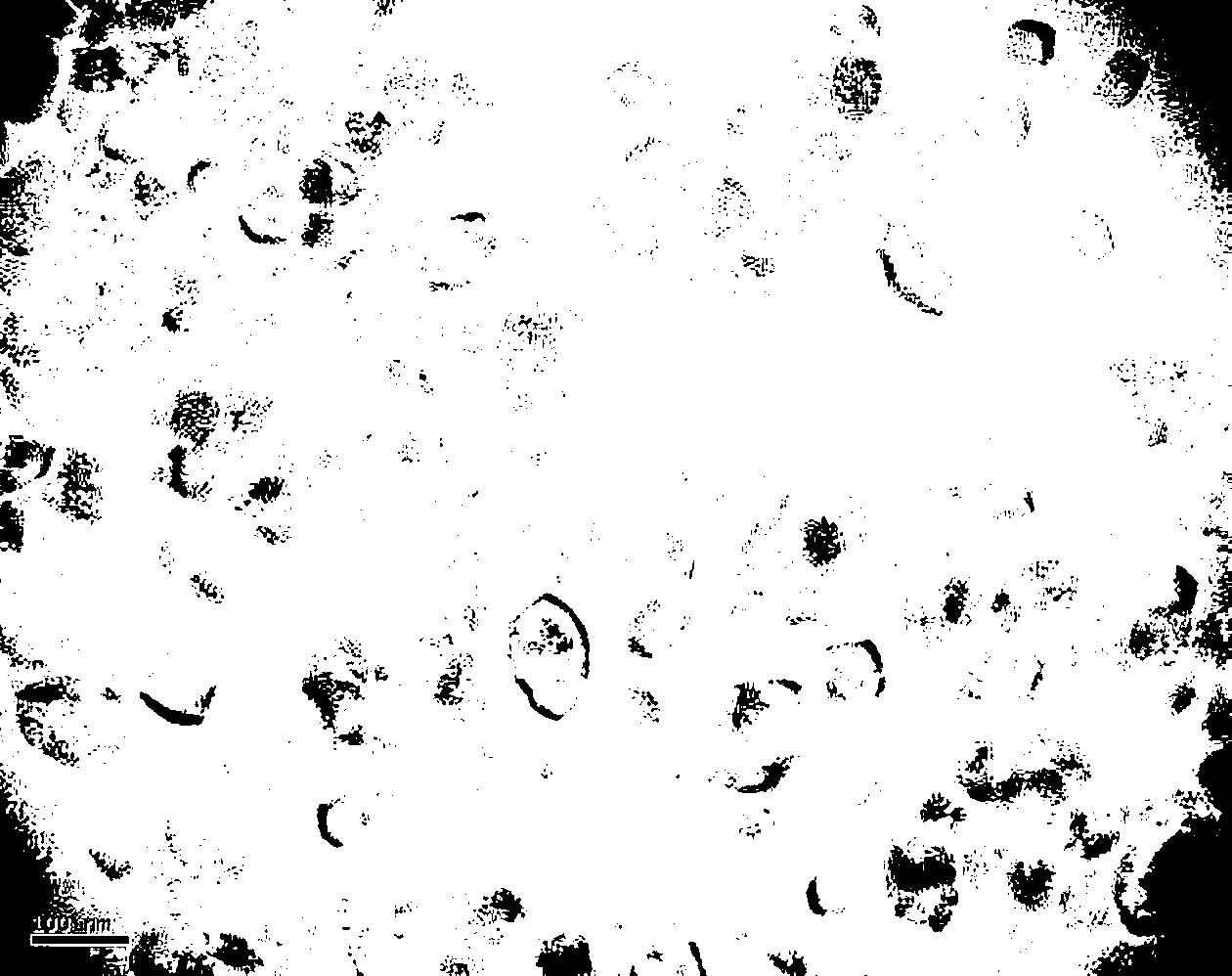

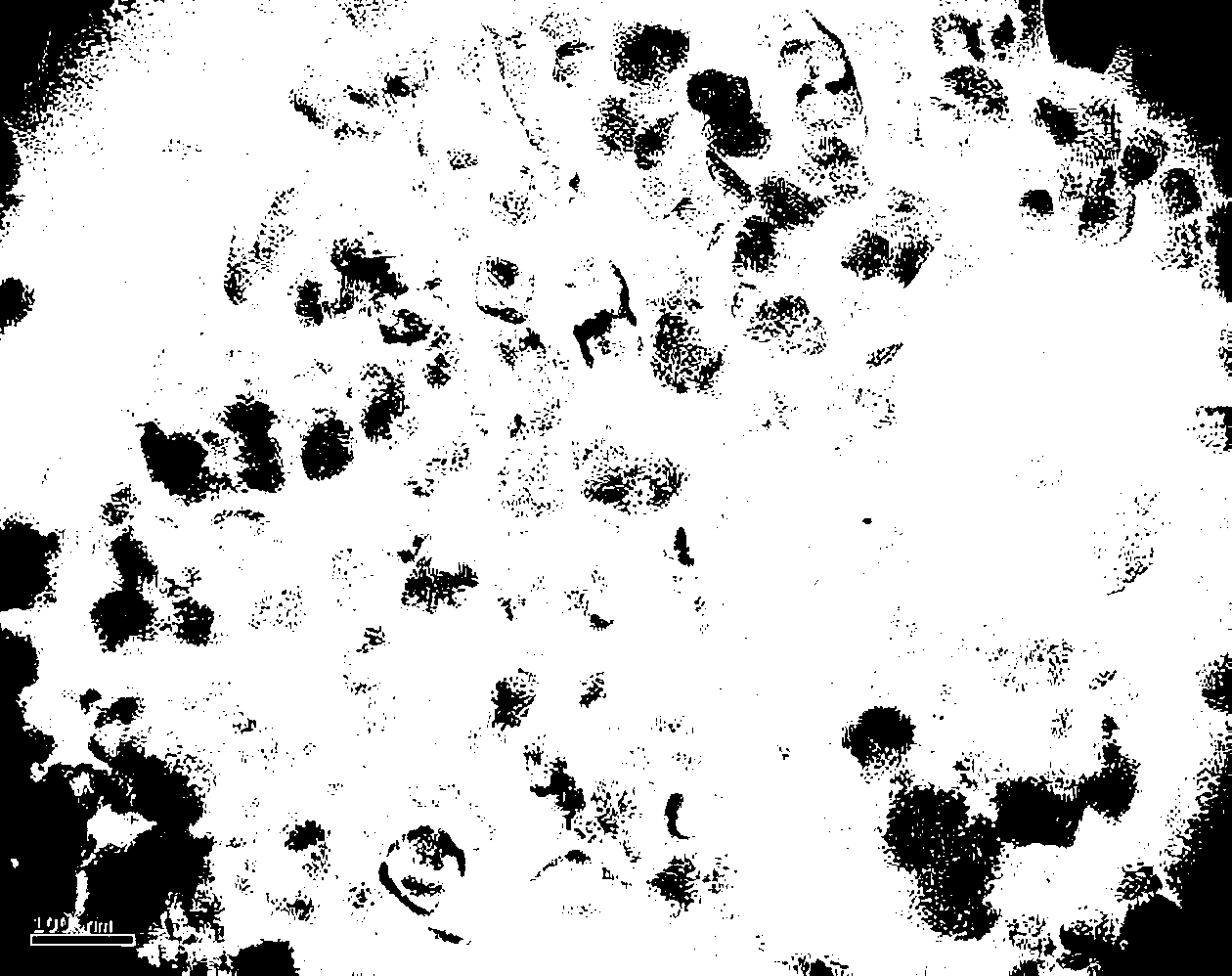

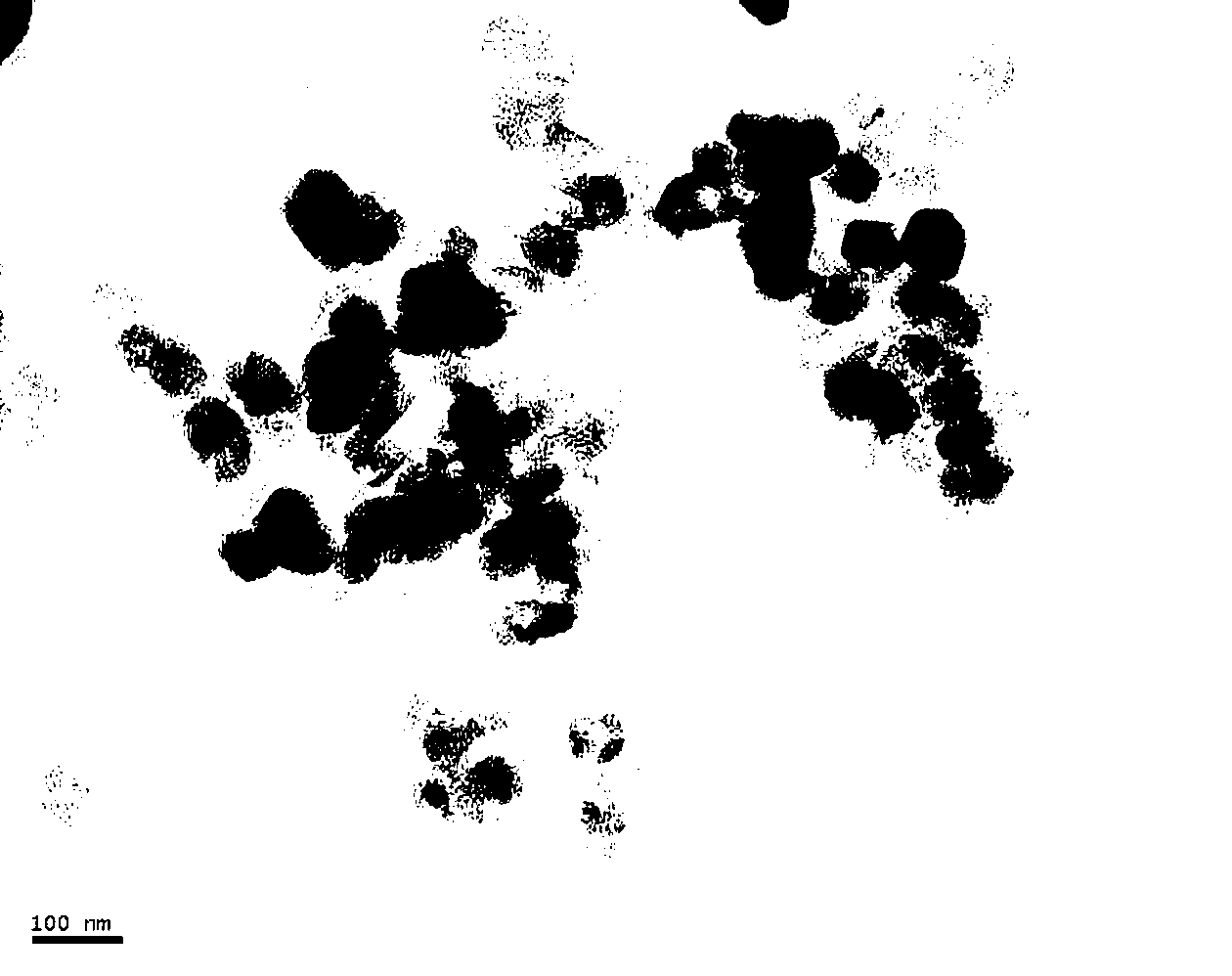

Image

Examples

Embodiment 1

[0033] A special high-strength nano-CaCO for silicone sealant 3 A preparation method comprising the steps of:

[0034] (1) Take CaCO 3 Natural limestone with a content greater than 98% is washed and calcined at 1000°C to generate CaO, and then digested in hot water at 60°C to generate Ca(OH) 2 Digestive fluid, the Ca(OH) 2 The digestive juice is sieved and purified, separated and removed to prepare Ca(OH) with a concentration of 10%. 2 suspension;

[0035] (2) The Ca(OH) obtained in step (1) 2 The suspension is placed in the carbonization reactor, and at the same time, the calcined flue gas that has been dedusted and purified in step (1) is passed into the carbonization reaction, and the CO in the calcined flue gas 2 The concentration of the gas is 30%, and the carbonization temperature is controlled at 22°C. When the carbonization reaches pH=7, CaCO is added to the carbonization solution to account for the carbonization reaction. 3 1.5% dispersant by weight, after stirr...

Embodiment 2

[0038] A special high-strength nano-CaCO for silicone sealant 3 A preparation method comprising the steps of:

[0039] (1) Take CaCO 3 Natural limestone with a content greater than 98% is washed and calcined at 1050°C to generate CaO, and then digested in hot water at 80°C to generate Ca(OH) 2 Digestive fluid, the Ca(OH) 2 The digestive juice is sieved and purified, separated and removed to prepare Ca(OH) with a concentration of 6%. 2 suspension;

[0040] (2) The Ca(OH) obtained in step (1) 2 The suspension is placed in the carbonization reactor, and at the same time, the calcined flue gas that has been dedusted and purified in step (1) is passed into the carbonization reaction, and the CO in the calcined flue gas 2 The concentration of the gas is 35%, and the carbonization temperature is controlled at 20°C. When the carbonization reaches pH=7, add CaCO to the carbonization solution to account for the carbonization reaction. 3 1.0% dispersant by weight, after stirring fo...

Embodiment 3

[0043] A special high-strength nano-CaCO for silicone sealant 3 A preparation method comprising the steps of:

[0044] (1) Take CaCO 3 Natural limestone with a content greater than 98% is washed and calcined at 950°C to generate CaO, and then digested in hot water at 50°C to generate Ca(OH) 2 Digestive fluid, the Ca(OH) 2 The digestive juice is sieved and purified, separated and removed to prepare Ca(OH) with a concentration of 8%. 2 suspension;

[0045] (2) The Ca(OH) obtained in step (1) 2 The suspension is placed in the carbonization reactor, and at the same time, the calcined flue gas that has been dedusted and purified in step (1) is passed into the carbonization reaction, and the CO in the calcined flue gas 2 The concentration of the gas is 35%, and the carbonization temperature is controlled at 17°C. When the carbonization reaches pH=7, add CaCO to the carbonization solution to account for the carbonization reaction. 3 0.5% dispersant by weight, after stirring for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com