Preparation method of environment-friendly and ageing-resistant calcium silicate ceramic fiber building insulation board

A technology of ceramic fiber and calcium silicate, applied in the field of ceramic fiber materials, can solve the problems of failing to meet the minimum requirements of the external wall thermal insulation system, poor plate strength, reduced rock wool board strength, etc., to improve the overall anti-aging performance, The effect of improving waterproof and moisture-proof performance and solving safety and environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A ceramic fiber building heat insulation board, its composition ratio is: 50 parts of calcium silicate fiber; 20 parts of rock wool scrap; 10 parts of expanded perlite; 5 parts of sepiolite fiber wool; 10 parts of clay; 4 parts of resin powder; 5 parts of moisture-proof agent; 1 part of silicone water repellent; 0.2 part of polyacrylamide, 0.1 part of polyaluminum chloride.

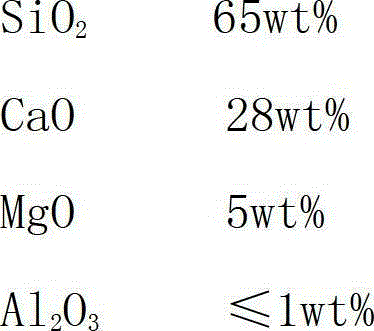

[0049] Described calcium silicate fiber is a kind of alkaline earth silicate fiber with SiO2 and CaO as main components, and its theoretical chemical composition is as follows:

[0050]

[0051] Calculate the acidity coefficient of calcium silicate fiber by chemical composition as follows:

[0052] Mk=wt(Al 2 o 3 +SiO2 2 ) / wt (CaO+MgO)=1.97.

[0053] The rock wool leftovers refer to leftovers produced during the production of rock wool boards for external wall insulation systems, wherein the acidity coefficient of rock wool fibers is controlled above 1.8.

[0054] The expanded perlite is ma...

Embodiment 2

[0063] A ceramic fiber building heat insulation board, its composition ratio is: 60 parts of calcium silicate fiber; 10 parts of rock wool scrap; 15 parts of expanded perlite; 5 parts of sepiolite fiber fleece; 8 parts of clay; 6 parts of resin powder; 3 parts of moisture-proof agent; 0.8 part of silicone water repellent; 0.2 part of polyacrylamide, 0.1 part of polyaluminum chloride.

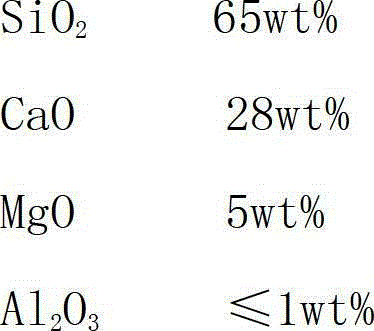

[0064] The calcium silicate fiber is a SiO 2 Alkaline earth silicate fiber with CaO as the main component, its theoretical chemical composition is as follows:

[0065]

[0066] Calculate the acidity coefficient of calcium silicate fiber by chemical composition as follows:

[0067] Mk=wt(Al 2 o 3 +SiO2 2 ) / wt (CaO+MgO)=1.97.

[0068] The rock wool leftovers refer to leftovers produced during the production of rock wool boards for external wall insulation systems, wherein the acidity coefficient of rock wool fibers is controlled above 1.8.

[0069] The expanded perlite is made of vitreous...

Embodiment 3

[0078] A ceramic fiber building heat insulation board, its composition ratio is: 70 parts of calcium silicate fiber, 12 parts of expanded perlite, 10 parts of sepiolite fiber fleece, 5 parts of clay, 5 parts of resin powder, 5 parts of moisture-proof agent, organic Silicon water repellent 1.5 parts, polyacrylamide 0.2 parts, polyaluminum chloride 0.1 parts.

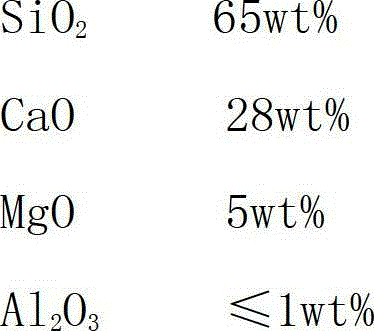

[0079] The calcium silicate fiber is a SiO 2 Alkaline earth silicate fiber with CaO as the main component, its theoretical chemical composition is as follows:

[0080]

[0081] Calculate the acidity coefficient of calcium silicate fiber by chemical composition as follows:

[0082] Mk=wt(Al 2 o 3 +SiO2 2 ) / wt (CaO+MgO)=1.97.

[0083] The rock wool leftovers refer to leftovers produced during the production of rock wool boards for external wall insulation systems, wherein the acidity coefficient of rock wool fibers is controlled above 1.8.

[0084] The expanded perlite is made of vitreous volcanic lava ore sand thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Cold compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com