Process for preparing 2,4-dichlorphenoxyacetic acid with high quality

A dichlorophenoxyacetic acid, high-quality technology, applied in the direction of carboxylate preparation, organic compound preparation, chemical instruments and methods, etc., can solve problems such as reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

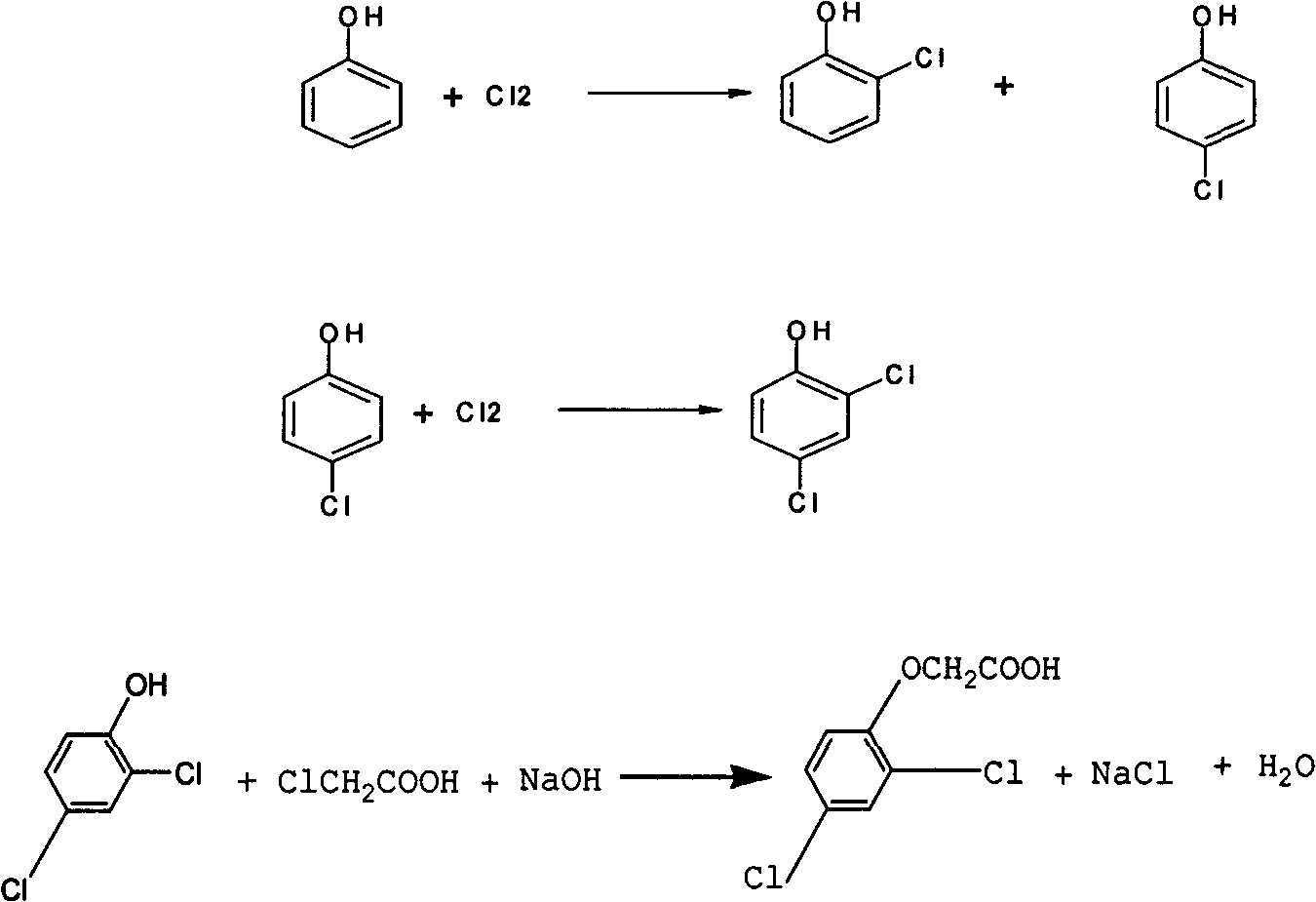

[0028] 1. Phenol chlorination to 4-chlorophenol:

[0029] (1) Take 1000 grams of phenol and put it into a 2000ml four-necked bottle, heat and melt it, and start stirring. Raise the temperature to 20°C, introduce the chlorine gas ventilation pipe under the phenol liquid surface, open the valve of the chlorine gas cylinder, start to feed chlorine gas, control the introduction of chlorine gas, keep the reaction temperature at 20-100°C, and optimally control it at 60-80°C. And absorb hydrogen chloride in the tail gas with water (for neutralization in the preparation of 2,4-dichlorophenoxyacetate). After 16 hours, when about 839 grams of chlorine gas was fed in, the mass percent content of phenol in the reaction solution was tracked by gas chromatography to be 0.1-0.5%, and the chlorine gas flow was stopped.

[0030] (2) At this time, the reaction solution is composed of (mass percentage content): 0.22% of phenol, 32.71% of 2-chlorophenol, 48.89% of 4-chlorophenol, 18.10% of 2,4-d...

Embodiment 2

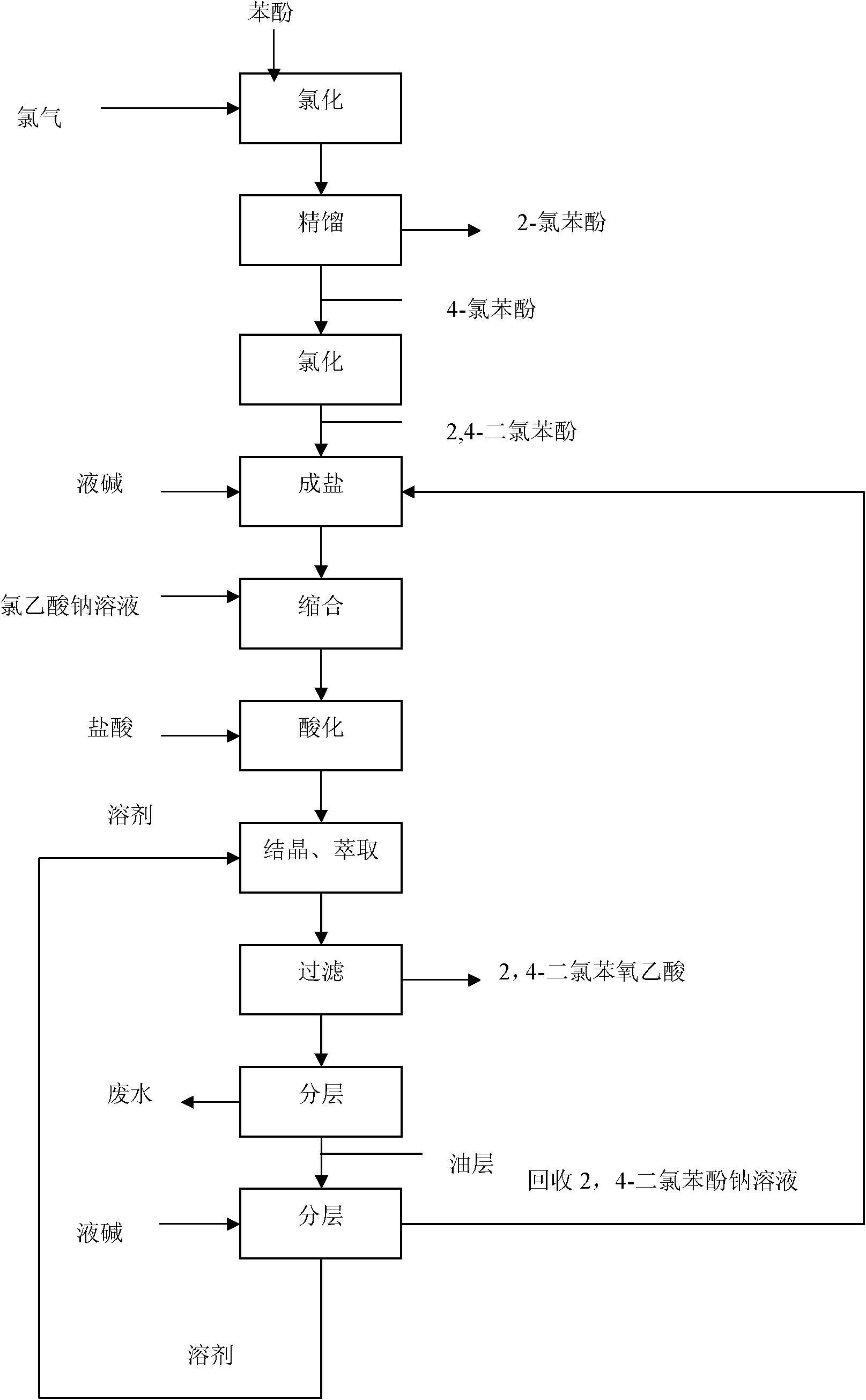

[0045] A kind of technique for preparing high-quality 2,4-dichlorophenoxyacetic acid, flow chart as figure 1 shown, including the following steps:

[0046] (1) Phenol is placed in the reaction kettle, and chlorine gas is passed into it, and the weight ratio of chlorine gas and phenol is controlled to be 2: 10, and the chlorination reaction temperature is 20° C., and 2-chlorophenol, 4-chlorophenol and 2-chlorophenol are prepared. , the mixture of 4-dichlorophenol, the mass percent content of residual phenol detected by gas chromatography is 0.5%, then the temperature is controlled to be 50°C, and the hydrogen chloride gas obtained by feeding inert gas is removed from the reaction;

[0047] (2) 2-chlorophenol is separated by rectification under reduced pressure, and the reaction temperature of rectification under reduced pressure is 110 ℃, and reaction pressure is 30mmHg;

[0048] (3) continue to pass into chlorine and carry out chlorination reaction, control reaction temperatu...

Embodiment 3

[0051] A process for preparing high-quality 2,4-dichlorophenoxyacetic acid, comprising the following steps:

[0052] (1) Phenol is placed in the reaction kettle, and chlorine gas is passed into it, and the weight ratio of chlorine gas and phenol is controlled to be 3: 10, and the chlorination reaction temperature is 60° C., and 2-chlorophenol, 4-chlorophenol and 2-chlorophenol are prepared. , the mixture of 4-dichlorophenol, the mass percent content of residual phenol detected by gas chromatography is 0.6%, then the temperature is controlled to be 80°C, and the hydrogen chloride gas obtained by feeding inert gas is removed from the reaction;

[0053] (2) 2-chlorophenol is separated by rectification under reduced pressure, and the reaction temperature of rectification under reduced pressure is 110 ℃, and reaction pressure is 30mmHg;

[0054] (3) continue to feed chlorine and carry out chlorination reaction, control reaction temperature to be 60 ℃, react to detect 2 through gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com