Boiler flue structure

A technology of boiler flue and flue, which is applied in the structural design of coal-fired boiler flue and the field of structural design of coal-fired boilers. Increased effect of reducing fan energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to solve the problem of serious contamination of the boiler's high-temperature convection heating surface, the invention proposes a new boiler flue structure design. Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

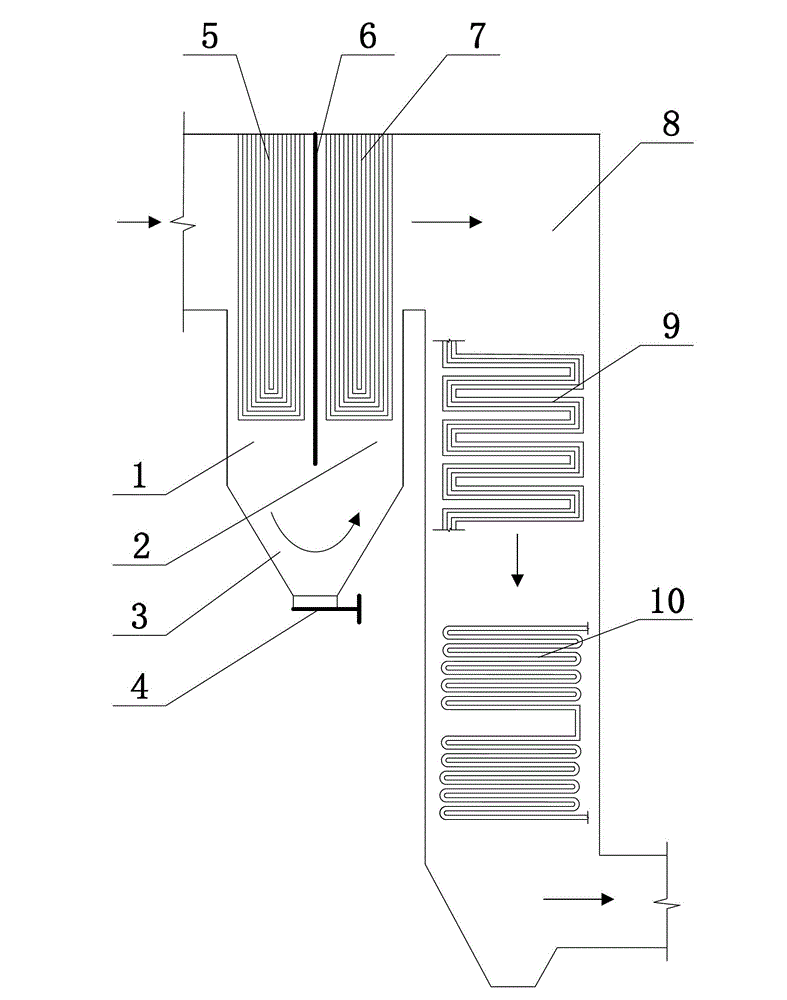

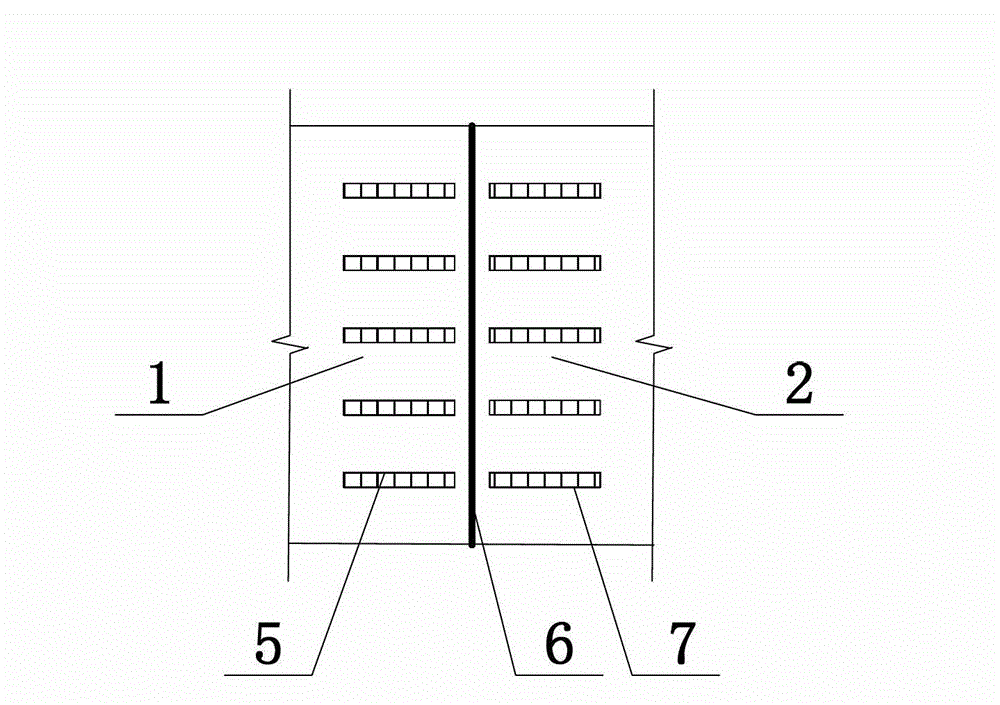

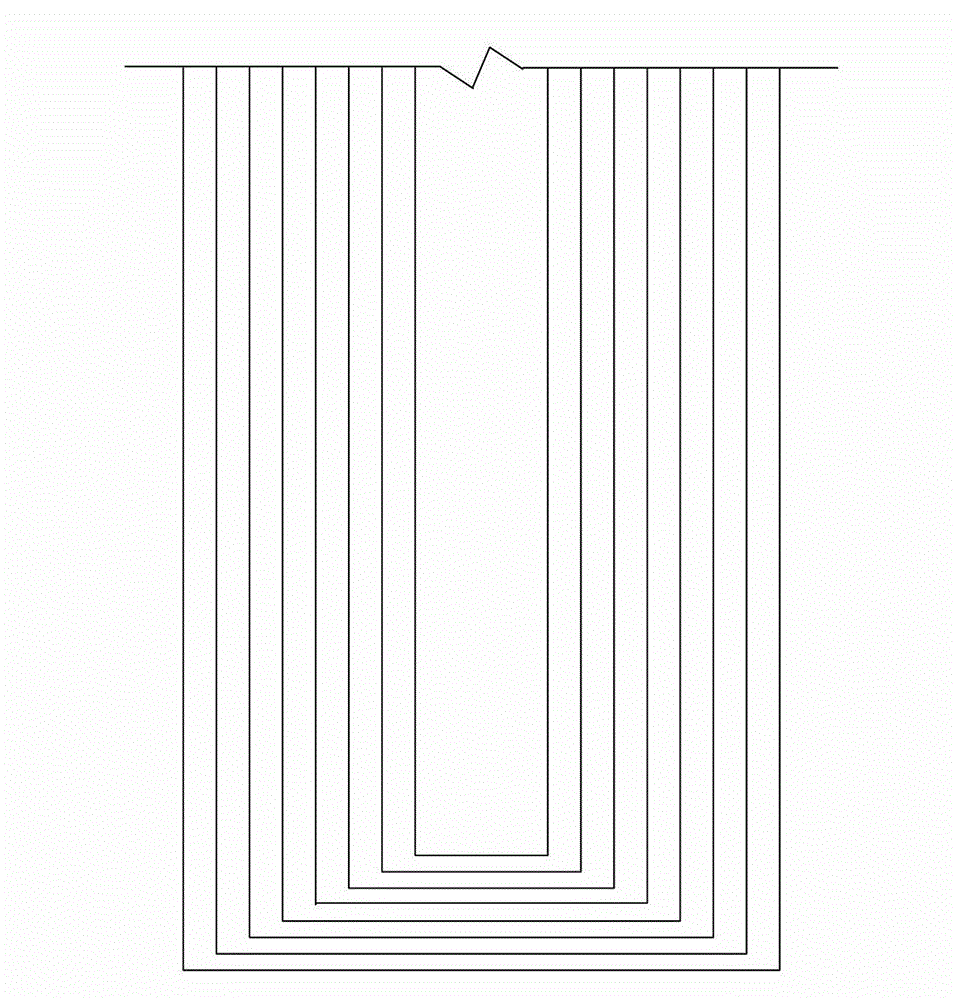

[0020] figure 1 A schematic diagram of a boiler flue structure provided by the present invention, such as figure 1 As shown, the flue includes a first flue 1 , a second flue 2 and a tail flue 8 . Between the first flue 1 and the second flue 2 is a water-cooled partition wall 6, and the two are connected to form a U-shaped passage through the ash hopper 3. A high-temperature reheater 5 is arranged in the first flue 1, and a high-temperature reheater 5 is arranged in the second flue. The final superheater 7 is arranged in the flue 2 , and the low-temperature reheater 9 and the economizer 10 are arranged in the tail flue 8 . The bottom of the ash hopper 3 is provided with an air loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com