Polybutylene terephthalate resin composition

A technology of polybutylene terephthalate resin and polybutylene terephthalate, applied in the field of polybutylene terephthalate resin composition, can solve mechanical problems of tensile strength and bending strength Reduced strength and other problems, to achieve the effect of excellent low moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

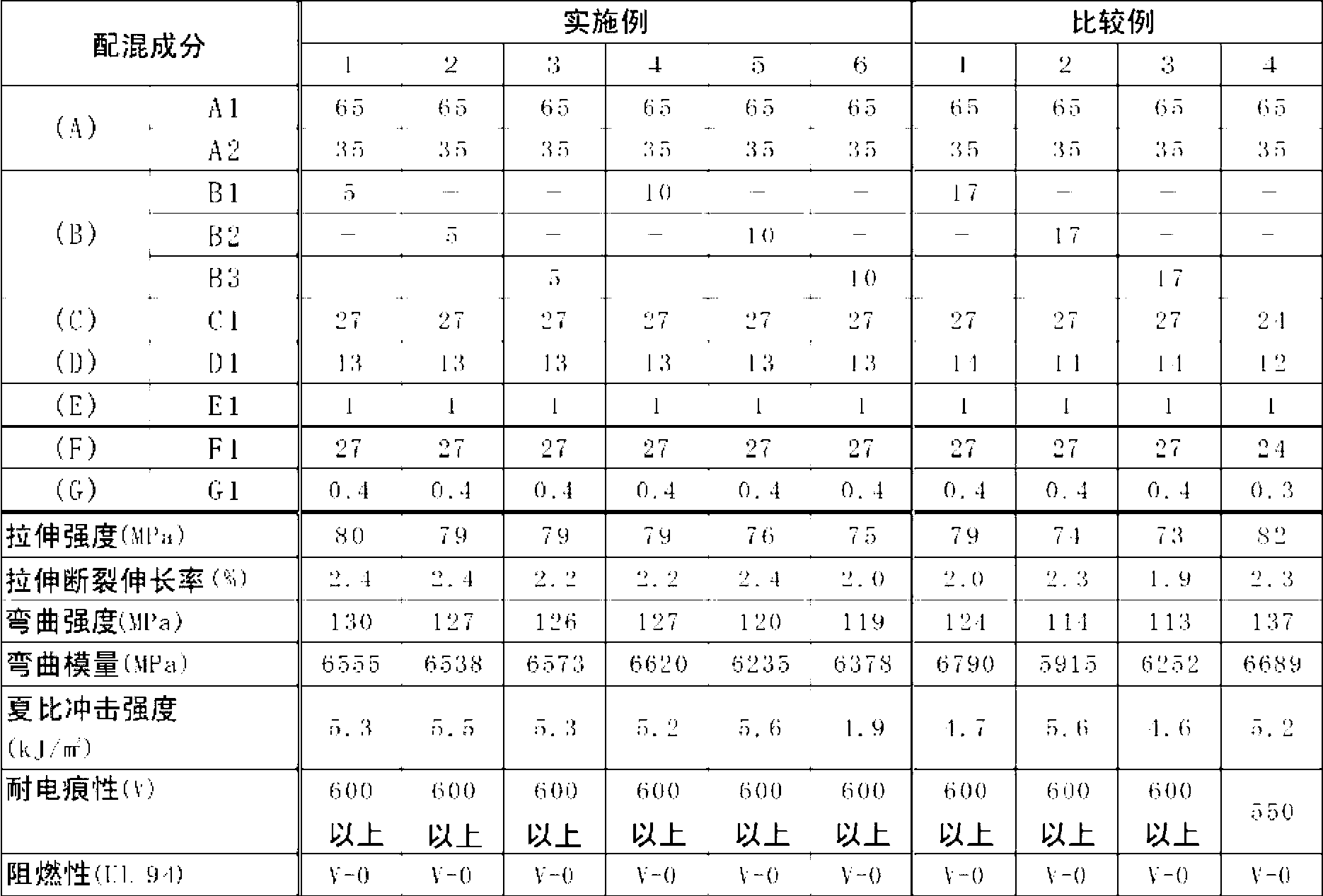

Embodiment 1~6 and comparative example 1~4

[0114] In Examples 1 to 6 and Comparative Examples 1 to 4, the following materials were used as components of the polybutylene terephthalate resin composition.

[0115] [(A) Polybutylene terephthalate resin]

[0116] A1: Polybutylene terephthalate resin with an intrinsic viscosity of 0.69 (manufactured by WinTechpolymer Ltd.)

[0117] A2: Polybutylene terephthalate resin with an intrinsic viscosity of 0.875 (manufactured by WinTechpolymer Ltd.)

[0118] [(B) Polyamide resin]

[0119] B1: Nylon 6 (made by Ube Industries, Ltd., UBENYLON (registered trademark) 1015B)

[0120] B2: Nylon 12 (manufactured by Daicel-Evonik Ltd., DAIAMID (registered trademark) X4442)

[0121] B3: Nylon 11 (made in Arkema K.K., Rilsan (registered trademark) BMNO)

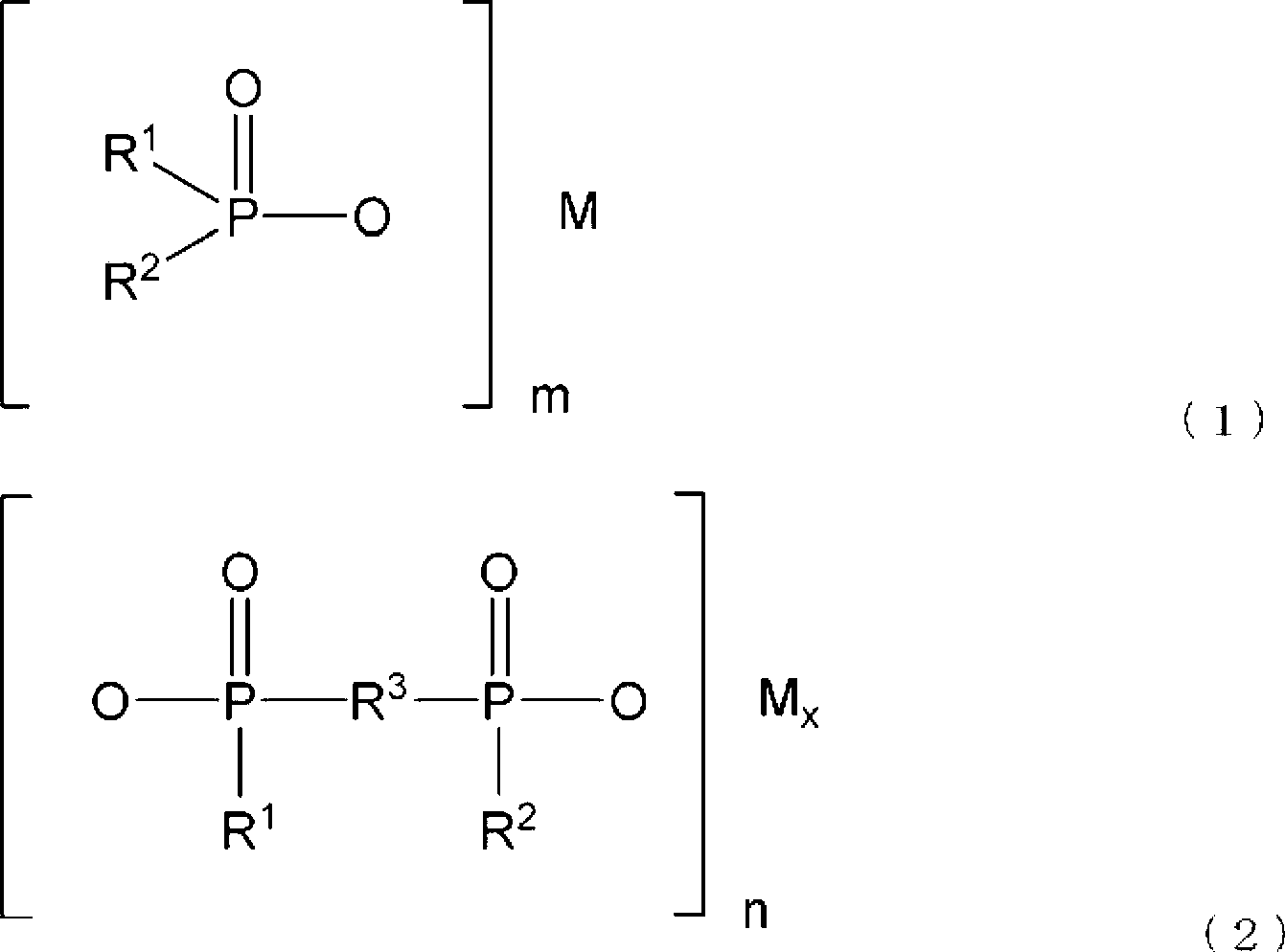

[0122] [(C) Organophosphorus flame retardants]

[0123] C1: aluminum tris diethyl hypophosphite (manufactured by Clariant (Japan) K.K., EXOLIT (registered trademark) OP1240)

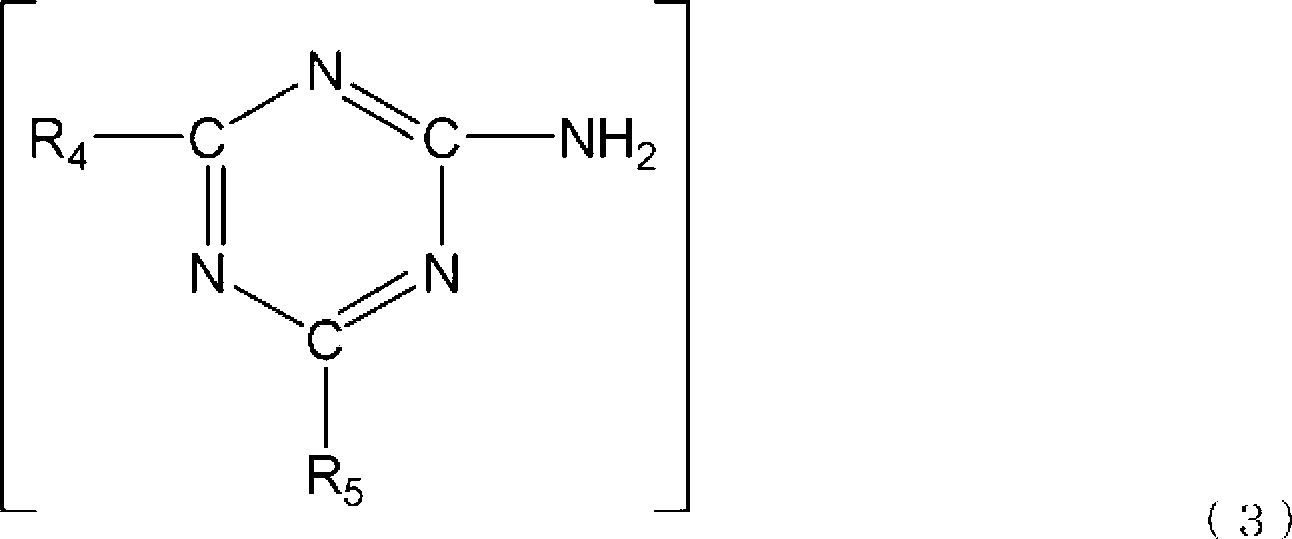

[0124] [(D) Nitrogen-containing flame retardant additives] ...

Embodiment 7、8、9 and 10

[0149] As Examples 7 and 8, a water absorption test was performed at a temperature of 23° C. and a relative humidity of 50%, and as Examples 9 and 10, a water absorption test was performed at a temperature of 23° C. and a relative humidity of 100%. The test pieces for the water absorption test were produced as follows: the polybutylene terephthalate resin composition obtained in Example 1 was used in Example 7 and Example 9, and the polybutylene terephthalate resin composition obtained in Example 8 and Example 10 was used. Using the polybutylene terephthalate resin composition obtained in Example 4, a sheet-shaped molded product having a size of 65 mm×55 mm×2 mm was injection-molded to produce it. The obtained test piece was vacuum-dried at 120° C. for 100 hours, and the weight of the test piece at this time was defined as the weight of the test piece at the start of the test. After measuring the weight of the test piece at the start of the test, the test piece was placed in a...

reference example 1 and 2

[0155] As Reference Example 1, a water absorption test was performed at a temperature of 23° C. and a relative humidity of 50%, and as Reference Example 2, a water absorption test was performed at a temperature of 23° C. and a relative humidity of 100%. The water absorption tests of Reference Examples 1 and 2 were performed in the same manner as in Examples 7 and 8 except that the test piece was produced using the polybutylene terephthalate resin composition obtained in Comparative Example 4. Table 2 shows the results of the water absorption test.

[0156] [Table 2]

[0157]

[0158] *: Content of the polyamide resin with respect to 100 mass parts of polybutylene terephthalate resins in a composition.

[0159] As can be seen from Table 2, compared with the tests of Reference Examples 1 and 2 using polybutylene terephthalate resin compositions that do not contain polyamide resins, using 100 parts by mass of polybutylene terephthalate In the tests of Comparative Examples 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com